Understanding Grms in Vibration Testing for ERM Motors: Key Metrics Explained

Grms in vibration testing for ERM motors means the root mean square acceleration measured in gravity units. You use Grms to see how strong the vibration is. This metric shows the average vibration level. It does this by taking the square root of the average of the squared acceleration values over time. When you check Grms, you get a clear idea of how the motor works. You also learn how reliable it will be when used.

Key Takeaways

Grms shows the average vibration strength in ERM motors. You can use it to check how well the motor works and if it is reliable.

Vibration testing finds possible motor problems. Doing tests often can stop problems like parts wearing out or not lining up right.

The ASD curve is important for finding Grms. It shows how vibration energy spreads over different frequencies. This helps you compare motors.

Use Grms with other checks like time-waveform and frequency analysis. This way, you get a better idea of motor health and possible damage.

Make motors with the right vibration strength. Use Grms numbers to set safe limits. This helps motors last longer.

ERM Vibration Motors Overview

What Are ERM Vibration Motors

ERM vibration motors are found in many devices. These devices need feedback or alert signals. The motors have an eccentric mass on the axle. When the motor spins, the uneven mass turns. This makes a centripetal force. The force causes the device to shake. You can see how the odd mass makes vibrations. This happens when you put it in different products.

Here are some main types and uses of ERM vibration motors:

Consumer electronics: You feel haptic feedback in phones and controllers.

Automotive: You get safety and comfort feedback in wheels and seats.

Medical devices: You receive alerts in prosthetics and health trackers.

Industrial uses: You notice sorting and alerting in factories.

Coin vibration motors are also called pancake motors. They are special because they are flat and small. You see them in tight spaces. They have a short shaft and a flat mass off-center. This helps them fit in small places.

The design of ERM vibration motors has some important parts:

Component | Function |

|---|---|

Eccentric Weight | Makes vibrations by spinning with uneven weight. |

Motor Shaft | Connects the motor to the weight and helps it turn. |

Bearings | Hold the shaft and help the motor run smoothly. |

Why Vibration Testing Matters

You need to test ERM vibration motors to check if they work well. Testing helps you see if the motors last long. Vibration testing lets you watch motor health and stop failures. You can make motors work better and find problems. These problems include looseness, misalignment, imbalance, worn parts, or resonance.

Industry standards help you test motors the right way. For example:

Standard | Description |

|---|---|

ISO 10816 | Rules for checking vibration in machines. |

ISO 7919 | Standards for measuring shaft vibration. |

API Standards | Used in oil, gas, and chemical industries. |

If you follow these standards, your motors meet safety and quality rules. You also get good results when you check how motors work in different places.

Grms in Vibration Testing

Grms Calculation

When you measure grms in vibration testing, you check the root mean square acceleration. This number shows how strong the vibration is over time. You use it to see the total energy a motor makes during a test. Grms is not just one reading. It comes from many acceleration measurements taken during the test.

You find grms by using the ASD curve. ASD means Acceleration Spectral Density. The ASD curve shows how much vibration energy is at each frequency. You look for the area under this curve. Then you take the square root of that area. This gives you the grms value. Here is how you do it:

You measure acceleration at different frequencies.

You plot these numbers to make the ASD curve.

You find the area under the curve.

You take the square root of the area to get grms.

Tip: The ASD curve helps you see how vibration energy spreads out. This makes it easier to compare motors or set a grms level for your tests.

Here is a quick summary of how the ASD curve helps you find grms in vibration testing:

The grms value comes from the ASD curve as the square root of the area under the curve.

This way shows the total energy of a random vibration event.

The ASD curve gives you the acceleration spectral density, which is important for finding grms.

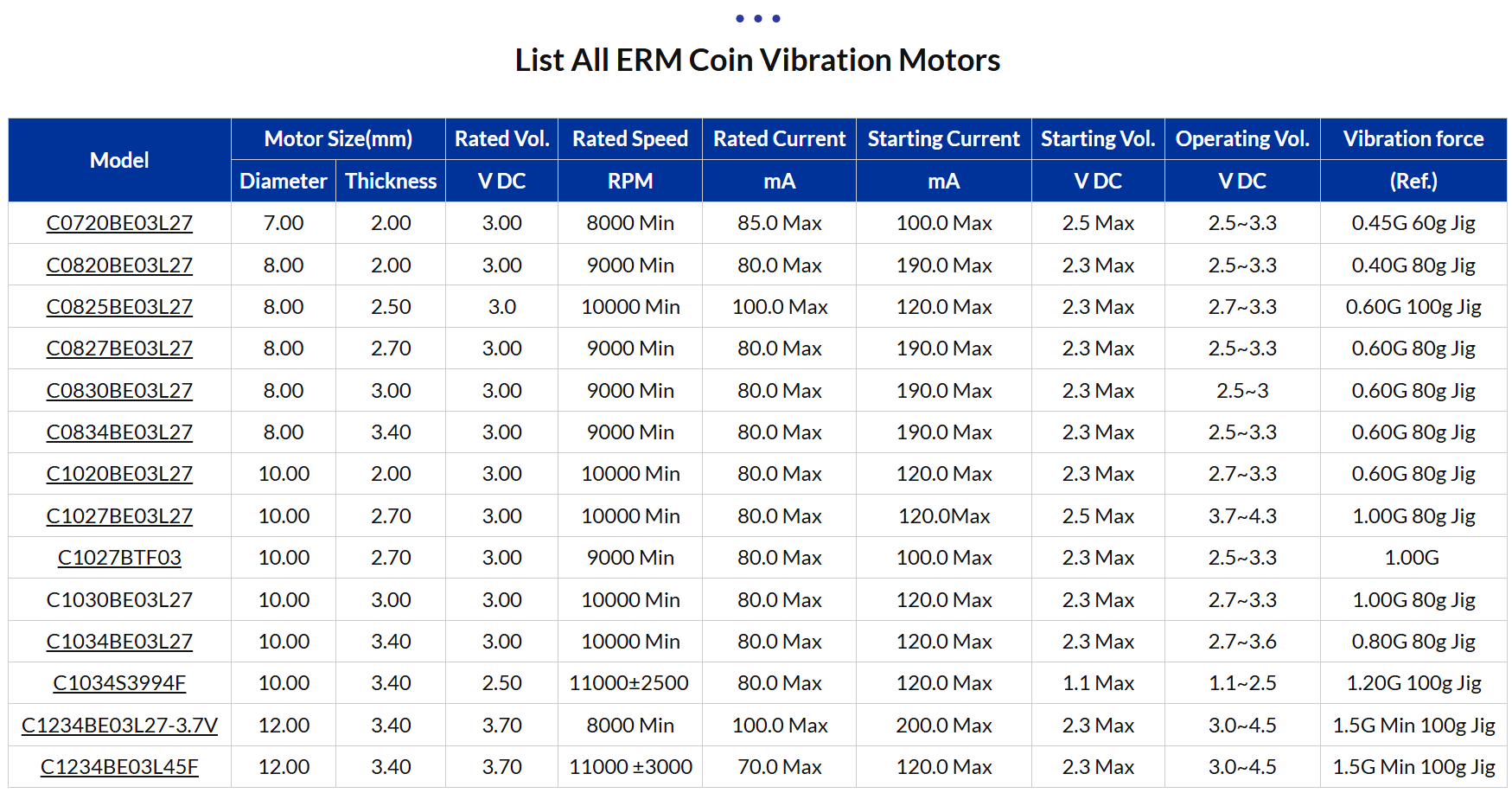

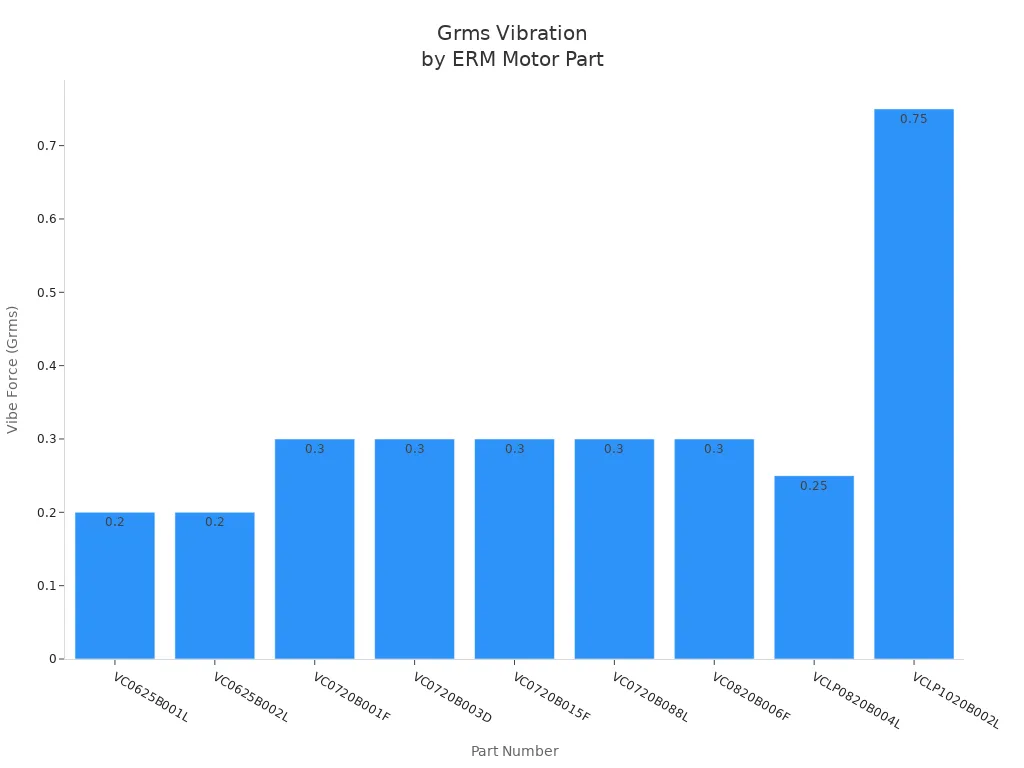

You often see different grms levels in ERM vibration motors. These levels help you compare how much vibration force each motor can make. Here are some common values:

You can also see these numbers in a chart for easy comparison:

Statistical Meaning of Grms

Grms in vibration testing gives you a way to measure the average vibration strength. It uses the root mean square acceleration to show how much energy the vibration motor makes over time. This number helps you see the overall effect of vibration on your motors. When you use grms, you get one number that sums up the vibration spectrum for the whole test.

You can use grms to compare motors or check if a motor meets your needs. Grms levels help you set limits for your tests. If you want to know how much stress your motors can take, you look at the grms value. This makes it easier to spot motors that might break early or need more help.

Grms gives you a wide view of vibration strength, but it does not show every detail. Other metrics can give you more information about the spectrum or the shape of the vibration. Here is a table that compares grms to other common metrics:

Metric | Description | Limitations in HALT Testing |

|---|---|---|

gRMS | Broad-spectrum intensity measurement providing a snapshot of the test spectrum at a specified time. | Does not account for frequency content, spectral shape, or differences in peak acceleration and kurtosis. |

Other Metrics | Typically include frequency content and spectral shape analysis. | Provide a more complete understanding of vibration effects under different test conditions and real-world situations. |

When you test ERM vibration motors, you use grms in vibration testing to get a clear picture of the average vibration force. This helps you make better choices about which motors to use in your products. You can also use grms levels to set safe limits for your vibration motor designs. By understanding the spectrum and using the right metrics, you keep your motors reliable and long-lasting.

Grms Impact on Motor Performance

Reliability Factors

When you look at ERM vibration motors, you want to know what makes them last longer. Grms gives you a way to measure vibration strength. This number helps you see what level of vibration can cause damage to your motors. If you use motors in a test, you can check the grms value to find out what vibration strength is safe.

You need to watch for damage from too much vibration. Motors with high vibration strength can wear out faster. You may see cracks, loose parts, or broken wires. The spectrum of vibration shows you what frequencies cause the most damage. If you see a wide spectrum, you know the motor faces many types of stress.

Here are some things that affect reliability:

High vibration strength can lead to early damage.

Motors with strong vibration may lose parts or stop working.

The spectrum helps you spot which frequencies cause the most damage.

You can use grms as a key metric to set safe limits for your vibration motor.

Tip: You should always check the spectrum during testing. This helps you find hidden damage before it gets worse.

You can use a table to see what types of damage happen at different vibration strengths:

Vibration Strength (Grms) | Possible Damage | Reliability Impact |

|---|---|---|

Low | Minor wear | Long motor life |

Medium | Loose eccentric weight | Shorter motor life |

High | Broken parts | Early motor failure |

Design Implications

When you design ERM vibration motors, you need to know what vibration strength your motor can handle. Grms helps you choose the right motor for your product. You can look at the spectrum to see what frequencies your motor will face. This helps you pick motors that will not break from too much vibration.

You can use grms to set design goals. If you want your motor to last longer, you pick a motor with lower vibration strength. You also look at the spectrum to make sure your motor can handle all the frequencies in your test.

Here are some design steps you can follow:

Check the grms value for each vibration motor.

Look at the spectrum to see what frequencies are present.

Choose motors with the right vibration strength for your product.

Test motors to make sure they do not show damage at expected vibration levels.

Use key metrics like grms to compare different motors.

Note: You should always test motors with the same spectrum you expect in real use. This helps you avoid damage that only shows up at certain frequencies.

You can use a checklist to help with motor design:

Does the motor have the right vibration strength?

Is the eccentric weight secure?

Can the motor handle the full spectrum of vibration?

Did the motor pass the test without damage?

Are the key metrics within safe limits?

When you use grms and other key metrics, you make better choices for your motors. You keep your vibration motors safe from damage and make sure they last longer in your products.

Limitations and Other Metrics

Grms Limitations

Grms measures the average vibration force in motors. It gives you one number for vibration strength. But it does not show all the details about vibration frequency. Grms cannot tell you which frequencies hurt the motor most. It also does not show how the eccentric weight changes the vibration pattern. If you only use grms, you might miss damage that happens at certain frequencies or in special tests.

Grms does not show short, strong bursts of vibration. Motors can have sudden spikes that cause damage. These spikes may not change the average grms much. You also cannot see if vibration changes quickly or stays the same. Life testing often needs more than grms to find early damage in motors.

Note: Grms is good for a quick look at vibration strength. But you should not use it alone to study motors fully.

Complementary Metrics

You can use other metrics with grms to learn more about motor health. These extra metrics help you find damage and understand vibration frequency. They also show how the eccentric weight affects the motor.

Time-waveform analysis shows how vibration changes over time. You can spot patterns that mean early damage or strange motor behavior.

Frequency analysis helps you find resonance. Resonance can make vibration stronger and cause more damage.

Machine learning methods can help you find faults. These models use vibration data to find hidden problems in motors.

Here is a table to compare these metrics:

Metric | What It Shows | How It Helps with Damage Detection |

|---|---|---|

Grms | Average vibration force | Finds general stress levels |

Time-Waveform | Vibration changes over time | Spots early or hidden damage |

Frequency Analysis | Vibration frequency and resonance | Finds damage from specific frequencies |

Machine Learning | Fault patterns in vibration data | Improves detection accuracy |

If you use these metrics together, you get a better view of motor health. You can find damage early and see how vibration affects motors. This helps you design motors that last longer. Using more than just grms helps you avoid problems that grms alone might miss.

Grms gives you a clear way to measure vibration strength in ERM motors. You can use this metric to compare motors and set safe limits. When you want a comprehensive view of vibration levels, you should also look at other metrics. New tools like the Mann–Kendall test, Mannagram, and Kendrum help you spot trends in vibration data. These advances make choosing the right motor easier and help you build products that last longer.

FAQ

What does Grms mean in vibration testing?

Grms stands for root mean square acceleration. You use it to measure how strong the vibration is in ERM motors. This number helps you compare different motors and check their performance.

What tools can you use to measure Grms?

You can use accelerometers and vibration analyzers. These tools record acceleration data. You then calculate Grms from this data. Most labs use digital equipment for fast and accurate results.

What does a high Grms value show about a motor?

A high Grms value means the motor creates strong vibrations. You may see more wear or damage if the value stays high. You should check if the motor can handle this level safely.

What other metrics help you understand motor vibration?

You can use time-waveform analysis, frequency analysis, and machine learning models. These metrics show vibration patterns, resonance, and hidden faults. You get a better view of motor health when you use them with Grms.

What happens if you only use Grms for testing?

If you only use Grms, you might miss damage from short spikes or certain frequencies. You should add other metrics to your tests. This helps you find problems early and keep motors reliable.

See Also

Exploring Motor Diagrams: Key Components and Their Uses

Decoding Motor Diagrams: Vital Parts and Their Roles

Understanding Motor Brushes: Key Elements for Optimal Performance

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry