8 Essential Vibration Tools Every Engineer Needs for Accurate Testing

You need good vibration tools for correct testing and checking. The right tools help machines work better. They also help stop machines from breaking down. These tools help you fix problems before they get worse. Good vibration measurement can really help:

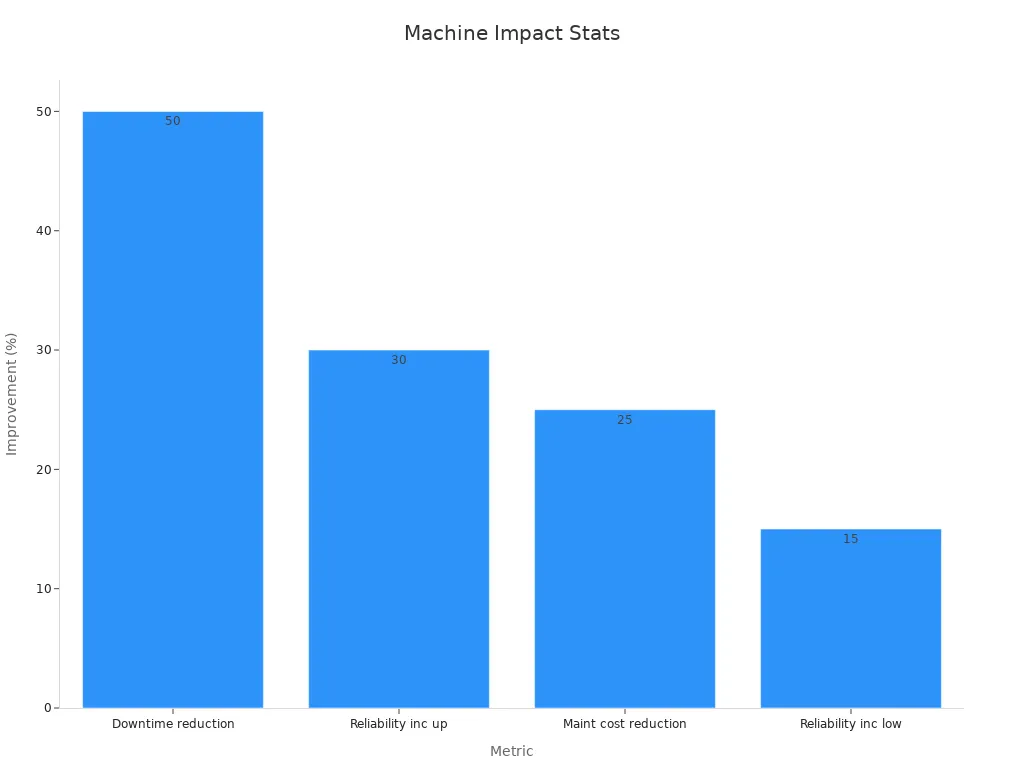

Metric | Improvement Statistic |

|---|---|

Downtime reduction | Up to 50% |

Equipment reliability increase | Up to 30% |

Maintenance cost reduction | 25% |

Equipment reliability increase | 15% |

Rules like ISO 10819 say you must measure vibration the right way for safety. Only good vibration checking with the right tools can keep engineers safe. It also helps make workplaces safer. Check your tools often to meet safety and testing needs.

Key Takeaways

The right vibration tools help engineers spot machine problems early. This lets them plan repairs and stop expensive breakdowns. Different tools have special jobs. Accelerometers measure movement. Laser vibrometers check things safely without touching them. Calibrating vibration tools often keeps measurements correct and trusted. This helps keep people safe and follows industry rules. Vibration meters and data systems give real-time, reliable data. This helps with better maintenance and safer workplaces. Advanced tools like signal analyzers and shaker tables help engineers study hard vibrations. These tools also help make products better.

1. Accelerometer

Overview

Accelerometers are very important for testing vibration. They check how fast something speeds up or slows down. Inside, there is a small proof mass. When something shakes, the mass moves. The sensor then measures this movement. Most accelerometers use capacitive, piezoresistive, or MEMS technology. MEMS accelerometers are liked because they are small and not expensive. They are also reliable. You can find them in many machines and devices. They work for both slow and fast vibrations.

Tip: MEMS accelerometers can check vibration from 1 Hz to 100 Hz with about 10% accuracy. They also measure still acceleration, which geophones cannot do.

Monitoring Applications

Accelerometers help you watch for many kinds of vibration. They let you check if machines are healthy. You can find early signs of problems and plan repairs. In building work, you watch vibration from big machines. In factories, you check motors and pumps. MEMS accelerometers give digital data and can connect to the internet. This makes it easy to collect and study information. Multi-axis accelerometers can measure vibration in more than one direction at once.

Here are some common uses:

Checking machines for repairs before they break

Sensing tilt and balance in big machines

Studying vibration in cars and airplanes

Importance

Accelerometers help keep people and workplaces safe. You need them to get good data. They help you follow safety rules and stop accidents. When you pick an accelerometer, match it to your job. Look for low noise, wide range, and good bias stability. MEMS accelerometers are a great choice for most jobs. They are accurate, small, and use little power.

Application Area | Key Selection Criteria |

|---|---|

Condition Monitoring | Low noise, wide range, low power |

Tilt Sensing | Bias stability, repeatability |

IoT Sensor Nodes | Very low power, small size |

Using the right vibration tools makes machines safer and better. Checking machines often with good tools helps you avoid big problems and plan repairs.

2. Vibration Meter

Overview

Vibration meters are small tools you hold in your hand. They help you check how much a machine shakes. You can see the results right away. Vibrometers measure vibration as it happens. They work for many different speeds, from 50 to 1000 Hz. The error is less than ±1.5%. This means you can trust what you see. Vibrometers use sensors like laser Doppler technology. This kind of sensor does not have as much noise as others. You can use vibration meters for quick checks or for watching vibration for a long time.

Note: If you use the same way to report frequency, acceleration, and duration, you can compare results from different machines and studies.

Key Uses

You can use vibration meters for many jobs at work. These tools help you:

Quickly check motors, pumps, and fans for vibration.

Watch how healthy a machine is and find problems early.

Compare good and bad machines using real-time data.

Help condition monitoring systems with fast, steady measurements.

Use them for checking one part or the whole machine.

Vibrometers give you almost the same results every time you test. If you check the same spot three times, the numbers are very close. This helps you trust the data when fixing machines. Axial vibration displacement checks can find problems sooner than other checks.

Why Essential

Vibration meters make checking for vibration fast and simple. They help you find problems before they get worse. If you find problems early, you can fix them before things break. Vibration meters also help with predictive maintenance by giving alerts right away. When you connect them to a vibration monitoring system, you get even more help. Real-time data lets you plan repairs and keep machines working well. Vibrometers help machines last longer and stop them from breaking down. They also help you follow safety rules and keep everyone safe.

Benefit | How Vibration Meters Help |

|---|---|

Early Fault Detection | Real-time vibration monitoring |

Maintenance Planning | Supports predictive maintenance |

System Reliability | Consistent, accurate measurements |

Safety Compliance | Meets industry standards for monitoring |

Tip: For the best results, use vibration meters with your condition monitoring systems to keep machines safe and working well.

3. Data Acquisition System

Overview

You need data acquisition systems to gather and save vibration data from machines. These tools connect to sensors and analyzers. They collect signals from accelerometers, microphones, and other devices. Data acquisition systems change analog signals into digital data. This makes it easy to use computers for analysis. You can use these systems for many jobs like vibration monitoring, quality control, and research. Modern systems have modular designs, so you can add more parts as needed. They work with many types of sensors. You can measure temperature, pressure, force, and more with the same setup.

Tip: Pick systems that follow rules like ISO 9001 or IEC 61010. This helps you get safe and reliable vibration data.

Vibration Data

Data acquisition systems are important for vibration testing. They collect real-time data from machines, so you do not miss changes. These systems sample analog signals at set times and turn them into digital values. This helps you track fast changes in vibration and find problems early. You can use these tools with condition monitoring systems to see how healthy your machines are. Data cleansing and validation steps help you trust the results. You can also use advanced analysis methods like time-domain and frequency-domain analysis to find hidden problems.

Data acquisition systems help with:

Real-time vibration monitoring

Fast and large data capture

Accurate and repeatable analysis

Working with analyzers and other tools

Importance

You depend on data acquisition systems for correct vibration analysis and decisions. These tools replace manual checks with sensor-based data collection. You get real-time feedback, which helps you fix and improve things quickly. The flexible design lets you add more sensors or channels when you need them. You can use these systems in many fields, like car testing or checking building health. When you use data acquisition systems with vibration monitoring, you make machines safer and more reliable. These tools help you plan repairs, avoid downtime, and keep machines working well.

Benefit | How Data Acquisition Systems Help |

|---|---|

Reliability | Real-time, high-integrity data capture |

Flexibility | Modular, scalable design |

Compliance | Meets industry standards |

Decision Support | Enables advanced analysis and reporting |

4. Signal Analyzer

Overview

Signal analyzers help you see what happens inside machines. These tools break down hard vibration signals into easy facts. You use them to turn raw data into patterns you can understand. Modern analyzers work with many sensors, like accelerometers and microphones. They collect data from different vibration tools. You can use signal analyzers in cars, planes, and power plants. They handle noisy and changing vibration data well. This makes them a top pick for engineers who need good results.

Analysis Functions

Signal analyzers give you many ways to study vibration. These tools use smart methods to help you find problems fast. Here are some main ways they help:

Analytical Method | Purpose / Application in Vibration Analysis |

|---|---|

Fast Fourier Transform (FFT) | Changes vibration signals from time to frequency to show machine problems. |

Wavelet Analysis | Looks at vibration data at different times and frequencies to find special issues or quick events. |

Envelope Analysis | Finds high-frequency changes to spot gear or bearing problems. |

Statistical Techniques | Makes normal patterns and finds changes that show possible trouble. |

Machine Learning | Teaches computers to see patterns in vibration for early problem finding. |

Spectral Analysis | Checks frequency parts to find resonance or odd things. |

Digital Twins | Builds computer models for early fixes, real-time checks, and testing ideas. |

You can also use filters, like Butterworth and Chebyshev, to take out noise. These tools help you focus on the most important signals. Many analyzers let you study time, frequency, and both together. This gives you a full view of machine health.

Why Essential

You need signal analyzers to test vibration the right way. These tools help you find faults before they get worse. You can measure things like displacement, velocity, and acceleration. This helps you find problems at different frequencies. Signal analyzers work with other vibration tools, like shakers and controllers. This gives you full control over your tests. You get very exact and trusted data. This helps you fix machines before they break. Many analyzers now use machine learning to find faults faster and make work easier. When you use these tools, your vibration checks are quicker, smarter, and more correct.

Tip: Use signal analyzers with your other vibration tools for the best results in machine checks and early repairs.

5. Impact Hammer

Overview

An impact hammer is used to hit things with a set force. This helps you see how things react to vibration. Engineers use impact hammers for dynamic vibration tests. The hammer has a force sensor inside. It records how hard you hit each time. You can pick different tips for different materials. Impact hammers work well in labs and outside. Field tests show more vibration than lab tests. This means you see what really happens in real life. The hammer’s design lets you get very exact and repeatable vibration signals.

Evidence Aspect | Details |

|---|---|

Number of Measurements | 144 field measurements (72 per handle) by 3 experienced users on concrete slabs |

Dominant Vibration Axis | Vertical (Z) axis showed highest transmitted vibration values, up to 22.59 m/s² |

Weighted RMS Acceleration | Highest values for 1525 hammer: 19.3 m/s² (main handle 20.04 m/s², side handle 18.56 m/s²) |

Statistical Significance | Significant differences between hammer models (p < 0.0001); no significant difference between two comparable tools (p = 0.89) |

Frequency Content | Dominant frequencies for electric hammers below 400 Hz |

Field vs Laboratory | Field measurements showed higher vibration levels than lab/robotic tests |

Practical Implications | Field data supports evaluation of user exposure and control strategies |

Testing Applications

Impact hammers are used for many jobs. You can check bridges, buildings, and machines with them. In car and airplane work, you test parts for cracks and wear. Impact hammers also help measure the natural frequency of concrete sleepers. If a sleeper is damaged, its natural frequency drops by up to 57%. This helps you find problems early. The hammer’s sensor and special design let you measure force and frequency well. You can change the hammer tip to fit your test.

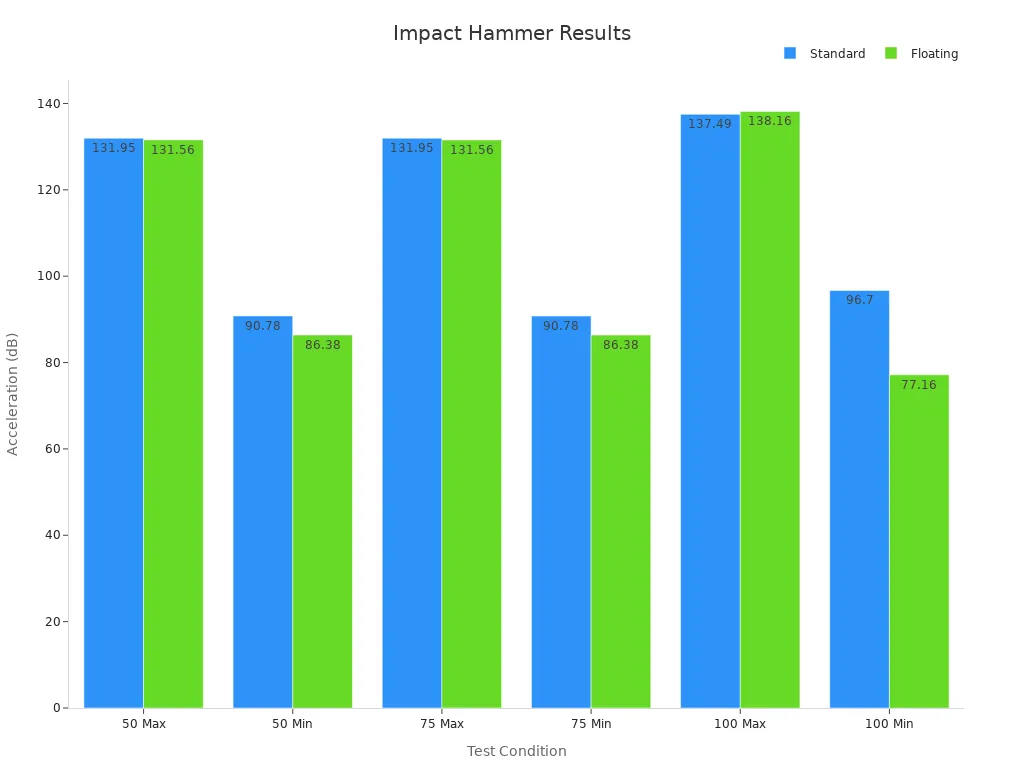

Parameter | Standard Fastener Vertical Acceleration (dB) | Floating Fastener Vertical Acceleration (dB) | Frequency Range (Hz) | Height (mm) |

|---|---|---|---|---|

Max vertical acceleration | 131.95 | 131.56 | 80-200 | 50 |

Min vertical acceleration | 90.78 | 86.38 | 6.3-12.5 | 50 |

Max vertical acceleration | 131.95 | 131.56 | 80-200 | 75 |

Min vertical acceleration | 90.78 | 86.38 | 6.3-12.5 | 75 |

Max vertical acceleration | 137.49 | 138.16 | 160 | 100 |

Min vertical acceleration | 96.7 | 77.16 | 1-12.5 | 100 |

Importance

Impact hammers are very important for vibration tests. You can trust the data because it is steady and clear. The hammer helps you find hidden damage by measuring force and frequency. You keep people safe by finding weak spots early. In building work, you check tunnels and bridges for strength. In factories, you watch machines to stop breakdowns. The data helps you design better products and follow safety rules. Using impact hammers makes sure your vibration checks are right and your workplace is safe.

Tip: Always pick the right hammer tip and force for your job. This gives you the best vibration results and keeps you safe.

6. Laser Vibrometer

Overview

A laser vibrometer checks vibration without touching the object. It shines a laser on the surface and reads how it moves. This tool works well for things that are hard to reach or very delicate. You get good results even if the surface is dark or rough. It also works from far away. Many engineers use this tool in cars, planes, and science labs. The tool is easy to carry and set up anywhere.

Tip: Laser vibrometers use special software like OptoSCAN and OptoGUI. These programs help you see vibration live and control the tool from far away.

Non-Contact Measurement

Laser vibrometers are great because they do not touch the thing you test. This means you do not change how it vibrates. This is important for small or fragile parts. You can measure from more than 200 meters away. You do not need to do anything to the surface first. The tool works on many surfaces, even if they are dark or rough. You can use it to check one spot or scan a whole area for a full picture.

Main benefits of non-contact measurement:

No damage to delicate equipment

Good vibration data from far away

Quick setup and easy to use outside

Clear results for careful study

Studies show scanning laser vibrometers can map vibration on tricky shapes, like faces or blades, without problems. You get steady data with errors less than 4.0 dB. This way helps with research, checking quality, and making sure machines work well.

Feature/Aspect | Description/Benefit |

|---|---|

Measurement Distance | Over 200 m, no need to prepare the surface |

Surface Reflectivity | Works on dark, rough, or living surfaces |

Data Quality | High detail (up to 32-bit), wide range >220 dB, live analysis |

Applications | Building checks, planes, cars, factories, and living tissue |

Safety Considerations

Laser vibrometers help keep people safe at work. You can measure vibration from far away. You do not need to stand near moving or risky machines. This lowers the chance of getting hurt. Many new laser vibrometers have safety tools like emergency stops and sensors. These help protect you and your team during tests.

Note: Using safety devices like laser scanners and emergency stops can cut machine injuries by up to 70%.

A good plan with vibration checks, laser tools, and safety steps can lower surprise breakdowns by 60%. Almost half of injuries with spinning machines happen because safety steps are missing. Always follow safety rules, look for dangers, and use controls to keep everyone safe.

Safety Statistic | Best Practice | Explanation |

|---|---|---|

60% fewer breakdowns | Use vibration checks and good care | Find problems early and watch machines |

50% of injuries from bad safety | Use strong safety plans | Controls and training stop accidents |

70% fewer injuries | Use smart safety features | Devices stop machines and keep people safe |

Laser vibrometers give you a safe and trusted way to check vibration and protect your workplace.

7. Shaker Table

Overview

A shaker table helps you make vibration in a lab. You use it to see how parts react to shaking. Shaker tables can move in one way or many ways. You can change how fast and hard they shake. This lets you copy real-life shaking. Engineers use shaker tables to test if products are strong. They check if things work well before using them. These tables help you find weak spots. You can make your designs better with this tool.

Tip: Shaker tables need calibration and checks. This makes sure the shaking is right. If you do these steps, you can trust your results.

Vibration Testing

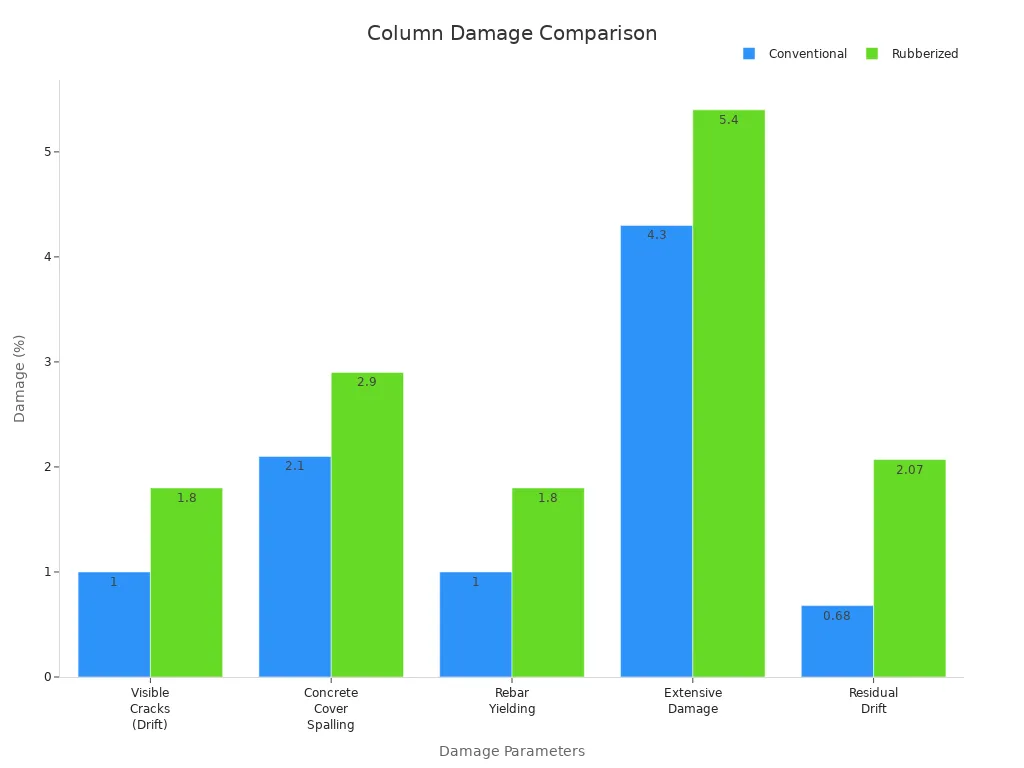

Shaker tables help you test vibration and check quality. You can do the same test over and over. This helps you compare results and see changes. You can test electronics, car parts, and building stuff. The table below shows how shaker tables help measure damage in concrete columns:

Parameter | Conventional Concrete Column | Rubberized Concrete Column |

|---|---|---|

Visible Cracks (Drift) | 1% | 1.8% |

Concrete Cover Spalling | 2.1% | 2.9% |

Rebar Yielding | 1% | 1.8% |

Rebar Fracture | N/A | N/A |

Extensive Damage | 4.3% | 5.4% |

Residual Drift | 0.68% | 2.07% |

Rubberized concrete columns have more drift and lose more energy. This shows shaker tables help you learn how materials act when they shake.

Importance

Shaker tables are important for vibration systems. You use them to check if your systems meet rules. These systems use special math to check if your data is right. Modal analysis helps you find natural frequencies and damping. This lets you make your systems work better. Shaker tables also use smart controls and can shake in many ways. These things help you copy real-life shaking better than computers. When you use shaker tables, you get good data for tests and checks. This helps you make your systems better and your products stronger.

8. Vibration Calibrator

Overview

A vibration calibrator checks if your vibration tools work right. It gives a set vibration signal you can trust. You use it to test vibrometers, sensors, and other tools. Many calibrators have a quartz reference accelerometer inside. This helps you get very exact results. Some models, like the 9210D, use closed-loop control. This makes calibration quick and simple. You can test many frequencies, from 0.7 Hz up to 2 kHz. Most calibrators also make ISO 17025 certificates. These certificates show your results are correct and can be trusted.

Tip: Always pick a calibrator with a test uncertainty ratio (TUR) of at least 4:1. This means your calibrator is much more exact than the tool you check.

Calibration Role

A vibration calibrator helps you find and fix mistakes in your vibration tools. You can spot random and systematic errors. Systematic errors cause bias and do not go away with more tests. Calibration lets you fix these errors and get better results. You also use calibrators to check if your data matches big standards. This keeps your results trusted everywhere.

Here are important steps for calibration:

Use labs with ISO/IEC 17025 approval for good results.

Make sure your calibrator matches national standards like NIST.

Keep a list of your tools and set times for calibration based on risk.

Track your certificates, uncertainty numbers, and test conditions.

Use digital reminders for when calibrations are due.

Remove and check any calibrators that are out of tolerance.

Follow extra rules for special jobs, like planes or dangerous places.

Why Essential

You need vibration calibrators to keep your data right and your tests useful. If you skip calibration, your tools may give wrong answers. This can make you miss problems or get false alarms. Calibrators help you follow rules and pass checks. They also help keep workers safe by making sure your tools work well. Studies show that using calibrated tools gives better results and fewer mistakes. For example, a vibration waveform classifier got 93% accuracy for non-decayed samples after calibration. This proves that calibration gives you better and more trusted data.

Benefit | How Vibration Calibrators Help |

|---|---|

Accuracy | Lower systematic errors and bias |

Compliance | Meet ISO and industry rules |

Reliability | Give steady measurement and data |

Safety | Help keep workers safe and stop downtime |

Note: Calibrate your vibration tools often to keep them ready for any job. This keeps your data, machines, and team safe.

When you pick the right vibration tools, your engineering work gets better. These tools help you test, watch machines, and keep workers safe. Each tool makes machines more reliable and helps with planning repairs. They also help you follow safety rules in many jobs. Engineers who use new tools see safer workplaces and better quality everywhere. The table below shows how these tools make work safer and machines work better:

Performance Aspect | Impact on Engineering Safety and Efficiency |

|---|---|

Early Problem Detection | Reduces repair costs and downtime through fast vibration analysis |

Smarter Maintenance Planning | Optimizes resources and improves quality in applications |

Safer Workplaces | Prevents accidents and supports improved safety for engineers |

Keep learning about new vibration tools and how to use them. If you have ideas or questions, share them. This helps other engineers do their best work.

FAQ

What is the most important vibration tool for beginners?

You should start with a vibration meter. This tool gives you quick, reliable results. It helps you check machine health and spot problems early. You can use it for many types of equipment.

How often should you calibrate your vibration tools?

You should calibrate your vibration tools at least once a year. If you use them in harsh environments or for critical tests, check them more often. Regular calibration keeps your data accurate and trusted.

Can you use one tool for all vibration tests?

You cannot use one tool for every test. Each tool has a special job. For example, accelerometers measure movement, while laser vibrometers check delicate parts without touching them. Use the right tool for the best results.

Why does non-contact measurement matter?

Non-contact tools, like laser vibrometers, let you measure vibration without touching the object. You avoid changing how it moves. This method works well for fragile, hot, or hard-to-reach parts.

What standards should you follow for vibration testing?

You should follow standards like ISO 10819 and ISO 17025. These rules help you get safe, reliable results. They also make sure your data matches what others use in the industry.

See Also

Top Ten Vibration Instruments Every Engineer Must Understand

Comprehensive Overview Of Phone Vibration Testing Techniques And Tools

Essential Guide To Selecting The Finest Vibration Measurement Devices

Different Techniques For Accurate Vibration Measurement Explained

Definitive Handbook For Effective Vibration Measurement Practices

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry