Interpreting Diagrams of a Motor: Essential Components and Their Functions in ERM Vibration Systems

Understanding motor diagrams is important for ERM vibration systems. These diagrams show essential components and their jobs. This helps improve how the system works. Learning this skill makes user experiences better, like in gaming. Accurate vibrations make games more fun. Knowing the main parts also makes fixing problems easier. It saves time and keeps the system working well.

Key Takeaways

Knowing motor diagrams helps improve ERM vibration systems. This makes fixing problems simpler and improves user experiences.

Eccentric Rotating Mass (ERM) motors make vibrations by spinning a heavy, uneven weight. They are used in phones and wearables for better haptic feedback.

Important parts of ERM systems include the uneven weight, motor shaft, and bearings. Each part helps create steady vibrations and smooth operation.

Check and maintain bearings and housing often to avoid problems. This care makes the motor last longer and keeps vibrations steady.

Learning to read motor diagrams is important. Focus on finding key parts and knowing their jobs to fix and improve performance easily.

Understanding ERM Motors and Their Role in Vibration Systems

What are ERM motors?

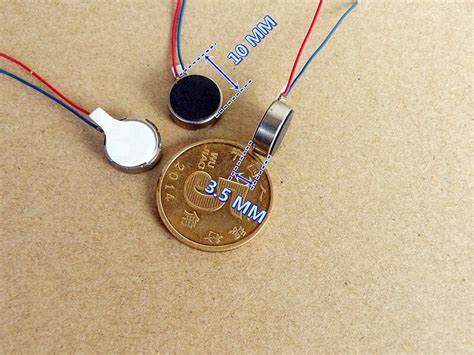

Eccentric Rotating Mass (ERM) motors are small devices. They create vibrations by spinning a weight that is off-balance. When the motor spins, this weight causes mechanical vibrations. ERM motors are used in devices needing vibrations or alerts. They are simple, reliable, and affordable for many uses.

These motors work in an easy way. The spinning weight makes a force that causes vibrations. This makes ERM motors great for phones, wearables, and machines. They give steady vibrations, perfect for haptic feedback needs.

Applications of ERM motors across industries

ERM motors are important in many fields. For example, in welding, they vibrate a welding rod to improve quality. Wearable tech also uses them. A European project made a vest with small ERM motors for touch feedback. This shows how they improve haptic technology.

You’ll also see ERM motors in healthcare, robots, and beauty tools. They fit in small spaces and give accurate vibrations. Whether in medical tools or game controllers, they make devices better with reliable feedback.

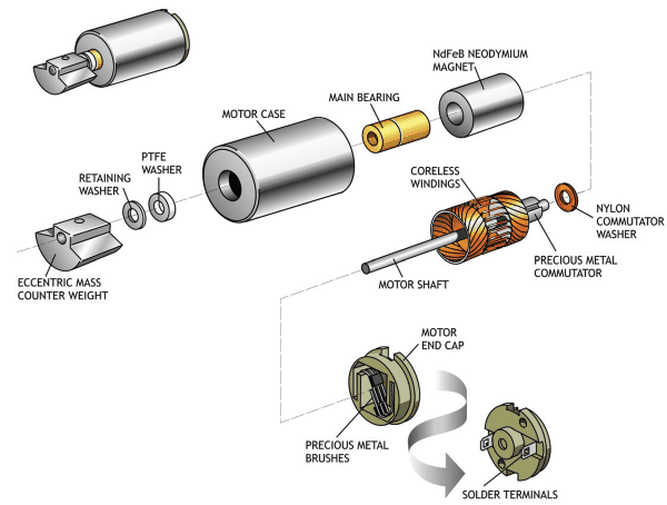

Why motor diagrams are essential for ERM systems

Motor diagrams help you understand how ERM motors work. They show parts like the weight, motor shaft, and wires. Studying these diagrams helps fix problems and improve performance.

For instance, knowing the motor’s voltage and current needs is important. Most ERM motors use 2 to 5 volts and 50 to 100 milliamps. Temperature and humidity can also affect how they work. Diagrams help pick motors for specific conditions, like -20°C to 70°C. This keeps motors lasting longer and working well.

Diagrams also explain technical details. Things like peak and RMS show how strong and steady the vibrations are. These details help you check if the motor fits your needs.

Essential Parts of an ERM Vibration System

Eccentric mass and how it makes vibrations

The eccentric mass is a key part of an ERM system. It helps create the vibrations you feel in devices. This mass is an uneven weight attached to the motor's spinning shaft. When the motor turns, the mass makes a pulling force. This force causes the motor to shake, creating vibrations for phones or wearables.

The size and position of the mass change the vibrations. A bigger mass makes stronger shakes, while motor speed changes how fast they happen. You can adjust these to fit different needs. For example, faster vibrations are good for touch feedback. Slower ones work better for general alerts.

Knowing how the eccentric mass works helps improve your system. It ensures the vibrations are strong and work well for your purpose.

Motor shaft and its role in spinning motion

The motor shaft is another important part of the system. It is the center rod where the eccentric mass spins. The shaft moves the motor's energy to the mass, making vibrations.

A good motor shaft keeps the spinning smooth and steady. This steadiness is needed for even vibrations. If the shaft wobbles, the vibrations won’t work right.

The shaft’s material and design also matter. Strong materials last longer and reduce damage. Good design saves energy and makes the motor work better. By focusing on the shaft, you can make your system more reliable.

Wires and power for the motor

Wires and connections power the ERM motor. They bring electricity to the motor so it can vibrate. These include wires, plugs, and connectors linking the motor to power.

Good connections keep the power flow steady. If power stops or changes, the motor may slow down. This can make the vibrations weak or uneven.

When setting up, check the wires and connections. Use strong materials and secure them tightly to avoid problems. Also, match the motor’s power needs, like voltage, to your power source. Good connections make your system work smoothly and reliably.

Bearings and housing for smooth operation

Bearings and housing are key for ERM systems to work well. They support moving parts and keep the motor steady. Without them, the motor might not work right. This could cause uneven vibrations or even damage.

What bearings do in ERM motors

Bearings are small parts that lower friction in the motor. They help the shaft spin easily, making vibrations steady. When the motor runs, bearings handle the stress from the spinning weight. This protects the motor and helps it last longer.

Think of bearings as quiet helpers. They save energy by reducing friction. Good bearings also make the motor quieter. This is important for devices needing silent, accurate vibrations.

Why housing matters for stability

The housing is like a shield for the motor. It protects against dust, water, and damage. A good housing also cools the motor by letting heat escape. This stops the motor from getting too hot.

Housing also gives strong support. It holds the motor in place so vibrations stay steady. For example, in wearables, housing makes sure vibrations go to the user, not the device.

How bearings and housing work together

Bearings and housing team up to keep the motor stable. Bearings reduce inside friction, while housing protects and supports. Together, they make the system work smoothly.

In some motors, both must align perfectly for good vibrations. If either breaks, the motor won’t work well. This can hurt how the device feels to use.

Tips to care for bearings and housing

Check bearings and housing often to keep them working. Look for noise or weak vibrations as signs of problems. Clean the housing and keep bearings oiled. Taking care of these parts makes the motor last longer and work better.

Tip: Use strong bearings and tough housing for better results. Spending more on quality parts saves money on repairs later.

By knowing how bearings and housing help, you can improve your ERM system. They may not stand out, but they are vital for keeping everything running smoothly.

How INEED Vibration Motors Turn Energy into Vibrations

How eccentric rotation works in vibration motors

INEED vibration motors use eccentric rotation mass to make vibrations. This means an uneven weight, called an eccentric mass, is fixed to the motor's shaft. When the motor spins, the eccentric mass creates a pulling force. This force makes the motor shake, creating vibrations you feel in phones or wearables.

The speed of spinning and the size of the weight affect vibrations. Faster spinning makes quicker vibrations, while a bigger weight makes stronger ones. This method is great for haptic feedback, giving precise touch responses. For example, in gaming controllers, it makes the experience more realistic with lifelike vibrations.

Changing electricity into vibrations: The steps

INEED motors turn electricity into vibrations in a simple way. Electricity powers the motor, making its shaft spin. The spinning shaft moves the eccentric mass, which creates vibrations.

This process is smooth and works well, even in small devices. INEED motors are used in many haptic tools, like tactile motors. They waste little energy, so they work efficiently. By learning this, you can see how these motors bring haptic features to everyday gadgets.

Things that affect vibration performance

Many things can change how well vibration motors work. Knowing these helps you use them better:

If the motor is unbalanced, vibrations may feel uneven. Regular checks keep it steady.

Broken bearings or loose parts can make the motor unstable. This lowers the quality of vibrations.

Bent or misaligned shafts can cause strange vibrations, ruining the experience.

Matching the motor’s frequency to the system avoids noise and wasted energy.

Good sensors, like accelerometers, are key for checking vibrations. They spot problems early by tracking changes.

Fixing these issues keeps the motor working well and gives better haptic effects.

Tip: Compare vibration patterns to normal ones often. This helps find problems early, saving time and repairs.

Practical Tips for Reading Motor Diagrams

Finding key parts in motor diagrams

When you see a motor diagram, start by spotting the main parts. These usually include the motor shaft, eccentric mass, bearings, and wires. Each part has a job to make vibrations and keep things running smoothly. For example, the motor shaft moves energy to the eccentric mass, which creates the vibrations you feel in gadgets like wearables or game controllers.

To make it simpler, focus on the labels and symbols in the diagram. Most diagrams use common symbols for parts. A circle might show the motor shaft, and a rectangle could mean the housing. Learning these symbols helps you find parts faster.

Tip: Keep a chart of motor symbols nearby. It will help you understand diagrams quickly and correctly.

Learning diagram layouts and symbols

Motor diagrams are like maps showing how parts connect and work. Knowing the layout is important to read them well. Start by finding the power source. It’s often marked with symbols for wires or plugs. Trace the electricity path through the motor to see how it powers the vibrations.

Symbols give extra details. For example, a zigzag line might mean a resistor, and arrows could show current flow. These symbols explain how the motor works and how its parts fit together. Look closely at the eccentric mass and bearings, as they affect how good the vibrations feel.

Note: Advanced motor diagrams, like those for haptic devices, may have harder symbols. Take your time to study them carefully.

Avoiding mistakes when reading diagrams

Reading motor diagrams can be hard, especially for beginners. A common mistake is missing small details, like how the motor shaft lines up or where the eccentric mass is placed. These details are key for steady vibrations and good feedback.

Another mistake is mixing up symbols or layouts. For instance, confusing power wires with signal wires can cause wrong setups. Always check the diagram and compare it to the motor to avoid errors.

Lastly, don’t forget about closed-loop feedback systems. These systems use sensors to watch vibrations and adjust the motor in real-time. If the diagram shows closed-loop feedback parts, learn how they connect to the motor.

Tip: Start with easy diagrams before trying harder ones. This will help you get better and more confident.

Real-World Applications of INEED Vibration Motor Diagrams

Troubleshooting and fixing motor problems

Motor diagrams help find and fix problems fast. They show how parts like the motor shaft, eccentric mass, and bearings work together. If vibrations feel weak or uneven, check the diagram for loose wires or bent parts. For example, a bent shaft can cause strange vibrations. Damaged bearings might make noise or shake the motor.

Feedback systems are also helpful for solving issues. They measure things like speed and angles between parts. This data shows where problems are and helps you fix them. Some advanced systems even watch the motor in real-time. This lets you catch problems early before they get worse.

Tip: Compare the motor’s vibrations now to its normal patterns often. This helps you find problems early and avoid big repairs.

Improving performance for different uses

Motor diagrams are great for adjusting motors to fit your needs. By studying the diagram, you can change the eccentric mass or motor speed to get the right vibration strength. Faster vibrations are good for gaming controllers. Slower ones work better for medical tools.

Advanced systems make adjustments even easier. Feedback loops control speed, position, and torque. They collect live data so you can make precise changes. In factories, microprocessors help protect motors and keep them working their best.

Optimization Method | Rise Time (s) | Settling Time (s) | Control Quality (ZLG) |

|---|---|---|---|

Mountain Gazelle Optimizer (MGO) | 0.0478 | 0.0841 | Lower ZLG values |

Grey Wolf Optimizer | N/A | N/A | N/A |

Particle Swarm Optimization | N/A | N/A | N/A |

This table shows how different methods improve motor performance. Picking the right one gives faster results and better control.

Building systems with INEED vibration motors

Motor diagrams are key when building systems with INEED motors. They explain how each part works together. For example, the diagram helps you choose the right motor size and power for your project. It also shows how to connect the motor to other parts for smooth operation.

INEED motors can be customized for many designs. You can change wire lengths, connectors, or mounts to fit your needs. Whether you’re making a wearable gadget or a factory tool, the diagram acts as a guide for the best results.

Note: Always think about temperature and humidity when designing systems. These can change how well the motor works and how long it lasts.

Knowing motor diagrams and their main parts is very important. It helps you fix problems and make ERM vibration systems work better. INEED vibration motors are well-designed and can be customized. They are great for haptic uses like in healthcare, robots, and wearable devices. These motors give accurate touch feedback, making them useful in many fields.

Use this knowledge to improve your projects with haptic technology. Whether creating touch motors or testing vibration effects, these tools will help you succeed.

FAQ

1. What is the main purpose of a motor diagram?

A motor diagram shows how the motor works. It explains the parts, their connections, and how they work together. This helps you fix problems and improve how the motor performs.

2. How do you identify the eccentric mass in a motor diagram?

Find the uneven weight connected to the motor shaft. It’s usually labeled or drawn as the part that makes vibrations.

Tip: Look at the diagram legend for labels or symbols showing the eccentric mass.

3. Can you customize INEED vibration motors for specific applications?

Yes, INEED motors can be changed to fit your needs. You can adjust wires, connectors, mounts, and vibration strength. These changes make the motor work better for your project.

4. Why are bearings important in ERM motors?

Bearings lower friction and support the motor shaft. They help the motor spin smoothly, make vibrations steady, and last longer. Without bearings, the motor could break faster.

5. How do feedback systems improve motor performance?

Feedback systems watch vibrations and change motor settings instantly. They fix problems like uneven vibrations or misaligned parts to keep the motor working well.

Note: Advanced feedback systems can find problems early, saving time and repair costs.

See Also

Understanding 3V Motors: Uses, Specs, And Selection Tips

Battery-Powered Motors: Varieties, Uses, And Efficiency Strategies

Ultimate Guide To Vibration Motors: Varieties And Selection Factors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry