ERM Vibration Motors: How They Work and Where They’re Used

ERM vibration motors make things shake by spinning a small weight. The weight is not in the center of the motor shaft. You can find these motors in many things you use every day. They make your phone vibrate when you get a text. They also make your game controller shake during exciting parts. Many engineers pick vibration motors because they do not cost much. They also work well and last a long time.

ERM vibration motors are used in millions of smartphones and wearables every year. Experts think the market will grow by 6.7% each year from 2019 to 2033.

Parameter | Value/Range |

|---|---|

Rated voltage | 3.0 V DC |

Power consumption | 140-210 mW |

Frequency | 65-250 Hz |

Vibration force | 0.6 to 2.5 G peak-to-peak |

Lifetime cycles | Up to 200,000 cycles |

Endurance time | Up to 220 hours before failure |

These numbers show why vibration motors are important. They are used in many products for people and engineers.

Key Takeaways

ERM vibration motors make things shake by spinning a weight that is not centered. This is how phones and game controllers can vibrate.

You can change how strong the vibration feels by changing the motor's voltage. This makes the motor spin faster or slower.

ERM motors are liked because they are easy to use and not expensive. They also save energy and last a long time in many devices.

These motors are used a lot in electronics, cars, medical tools, and factories. They help give feedback and alerts to people.

When you pick a vibration motor, think about how fast you need it to go. Also think about how much power it uses, how you control it, and how long it will last. This helps you choose the best one for your project.

ERM Vibration Motors

Key Components

If you open up an erm vibration motor, you will see a few main parts. There is a small DC motor, a shaft, and a weight that is not in the center. The weight connects to the shaft but sits off to one side. This is what makes the motor shake.

Here is a table that lists how these parts work:

Parameter | Range / Values |

|---|---|

Input Voltage | 0.98 V to 3.15 V |

Frequency | 100 Hz to 240 Hz |

Amplitude (G) | 0.45 G to 2.35 G |

Duty Cycle (%) | 19.7% to 63.0% |

You can change how strong the vibration feels by changing the voltage or duty cycle. If you turn up the voltage, the motor spins faster and shakes more. Engineers use special tools called accelerometers to check how much the vibration changes. If you put the motor on something soft, like your arm, the shaking feels weaker because your skin and muscles soak up some of the force.

Tip: There are different kinds of vibration motors, but erm vibration motors are a favorite because they are easy to use and work well.

Eccentric Rotating Mass Principle

The main idea behind erm vibration motors is called the eccentric rotating mass principle. When you turn on the motor, the off-center weight spins around fast. This spinning makes the whole motor move back and forth. That is what you feel as vibration.

Scientists have tested these motors on people’s skin and on robots. They learned that the vibration starts very quickly, in about 105 milliseconds, and stops in about 136 milliseconds. This quick start and stop is good for things like phone alerts and wearable gadgets. The frequency and strength of the vibration always change together. You cannot change one without changing the other. This is different from some other vibration motors, which let you control them separately.

You see erm vibration motors in lots of products because they are small, do not use much power, and cost less than other types. Their simple design makes them easy to add to new devices.

How Vibration Motors Work

Operation Process

Have you ever wondered how vibration motors make things shake? It all starts when you give the motor DC voltage. This voltage turns on the small motor inside. The motor spins a shaft with a weight that is not in the center. When the shaft spins, the weight moves in a circle. This makes the whole motor shake.

Here is an easy guide to show how vibration motors work:

You use a battery or circuit to power the motor.

The motor starts spinning the shaft.

The off-center weight goes around and makes the motor vibrate.

The shaking moves through the device and reaches your hand or skin.

You feel the buzz, pulse, or shake as feedback.

Tip: The vibration always goes the same way. The brushes and commutator inside the motor keep the current moving one way. This design gives you steady feedback every time.

Vibration motors are used in many things to give feedback. For example, your phone vibrates when you get a message. A wearable can use feedback to help you during exercise. Engineers put these motors in armbands, shirts, or gloves for feedback in different places. Sometimes, a computer controls when and how strong the feedback is, like in robots or virtual reality.

You can check how well vibration motors work by looking at some key things:

Peak amplitude: Shows how strong the shaking feels.

Frequency spectra: Tells how fast the vibration is.

Power spectral density: Shows how much energy the vibration has.

To measure these things, you use tools like accelerometers, velocity sensors, and displacement sensors. These tools help you make sure the feedback is strong and clear.

Controlling Vibration Intensity

You can change how strong the feedback feels by changing the DC voltage. If you turn up the voltage, the motor spins faster. This makes the vibration stronger and easier to feel. If you lower the voltage, the motor slows down and the feedback is softer.

The speed and vibration are linked. When the motor spins faster, the vibration frequency goes up. You can find the frequency by dividing the speed in RPM by 60. This means you can control the feedback by changing the voltage.

Here are some ways to adjust feedback in your projects:

Use software to change the voltage or duty cycle.

Put more than one motor in different places for special feedback.

Try different vibration patterns to match the feedback you want.

Some advanced systems use a screen to control when and how feedback happens. For example, a robotic arm can use feedback to tell you if you are gripping too hard or too soft. The system can change the vibration strength based on how much force you use. This gives you feedback right away.

Note: The direction of vibration does not change when you change the voltage. The commutator and brushes keep the rotation steady, so the feedback always goes the same way.

You can make feedback better by using damping materials or mounts. These help soak up extra shaking and make feedback more exact. Checking with vibration analyzers helps you find problems early, like imbalance or wear, so feedback stays good.

If you want good control in your feedback system, you need to know how vibration motors work. This helps you make better devices and feedback that feels right for users.

Applications of Vibration Motors

Vibration motors are used in many things you use every day. You can find them in phones, cars, medical tools, and factories. Let’s see how these motors help in different areas and why engineers like them.

Consumer Electronics

Vibration motors are inside your phone, smartwatch, and fitness tracker. They let you know when you get a call, text, or alert. Games and apps use them to make things more fun with shakes and buzzes.

Phones use vibration motors for silent alerts and feedback.

Wearables and IoT devices use small motors for reminders or health updates.

Game controllers use them so you feel every crash or jump.

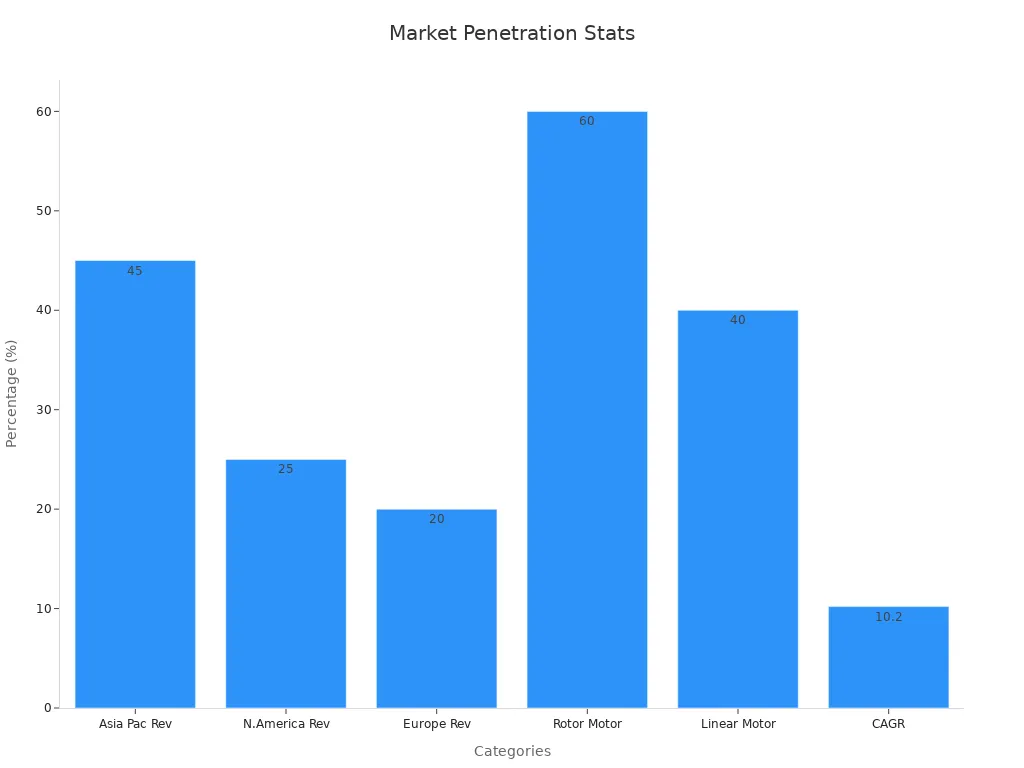

Here are some facts about the market:

Metric/Category | Statistic/Value |

|---|---|

Market Size (2024) | USD 2.5 Billion |

Projected Market Size (2033) | USD 5.8 Billion |

CAGR (2026-2033) | 10.2% |

Asia Pacific Revenue Share (2023) | 45% |

North America Revenue Share (2023) | 25% |

Europe Revenue Share (2023) | 20% |

Rotor Motor Segment Share | 60% |

Linear Motor Segment Share | 40% |

Smartphone Units Shipped (2023) | Over 1.5 billion |

Rotor motors, including ERM vibration motors, are in 60% of smartphones. Asia Pacific leads the market because there are many people and factories there.

Why do so many devices use ERM motors? They are simple, cheap, and work well. You can put them in expensive or budget products. Wearables and IoT devices need small, energy-saving motors, and ERM motors are a good fit. As more people use wearables and IoT devices, more ERM motors are needed.

Tip: If you want to add feedback to your gadget, ERM vibration motors are a smart choice because they balance price and performance.

Automotive Uses

Vibration motors help make cars safer and more comfortable. They give feedback through the steering wheel, seat, or dashboard.

Lane departure warnings buzz your seat or wheel if you drift.

Parking sensors use vibration to warn you when you get too close.

Car touchscreens use feedback so you know when you press a button.

ERM motors are strong and last a long time in cars. They work in hot or cold weather. You can trust them to give steady feedback for years.

Medical Devices

Many medical tools and wearables use vibration motors. They help patients and doctors by giving clear, gentle feedback.

Prosthetic arms and legs use vibration so users can feel touch or pressure.

Health trackers use feedback to remind you to take medicine or move.

Therapy devices use feedback to guide you during exercises.

Studies show ERM motors give steady feedback for all ages. You can use them in skin devices for therapy, like helping people with Parkinson’s disease. These motors send feedback right away to guide each step. Medical wearables and IoT devices use ERM motors because they are accurate, flexible, and easy to control.

Note: If you design a medical device, ERM motors can help patients and make feedback easy to understand.

Industrial Applications

Factories, machines, and smart sensors use vibration motors. They help with sorting, alerting, and testing.

Machines use vibration to move parts on a conveyor belt.

Sensors use feedback to warn about problems or errors.

Industrial IoT devices use vibration to send alerts or guide workers.

Here is a table showing why ERM motors are good for factories:

Metric | Description |

|---|---|

Voltage | ERM motors run at 3V DC, perfect for industrial uses. |

Current Consumption | 85mA to 100mA, showing good power efficiency. |

Speed (RPM) | 9000 to 10000 RPM, giving strong and steady vibration. |

Vibration Strength | 0.80 to 0.91 GRMS, enough for most tasks. |

Durability Testing | Motors pass thermal cycling and vibration tests for tough environments. |

Lifespan | Some motors last up to 1 million cycles under stress. |

You can count on these motors for feedback in tough places. They pass tests for heat, moisture, and dust. You get strong, steady feedback and do not have to worry about breakdowns. This makes them a top pick for factories where reliability and strength matter most.

Tip: If you want to build a smart factory or add feedback to machines, ERM vibration motors give you the strength and long life you need.

ERM vs Other Vibration Motors

ERM vs LRA

When you compare vibration motors, you see two main types: ERM and LRA. Each type has things it does well and things it does not. You should know these differences before you pick one for your project.

Here is a table that shows how ERM and LRA motors work in important ways:

Parameter | ERM Motor Characteristics | LRA Motor Characteristics |

|---|---|---|

Input Voltage | 0.3 V to 3.15 V | About 1.2 V (low voltage) |

Frequency Range | Wide: ~100 Hz to ~240 Hz | Narrow: 60 to 285 Hz (resonant frequency) |

Vibration Amplitude | 0.45 G to 2.35 G | Precise control, depends on weight and damping |

Step Response | Slow: 50 to 100 ms (inertia) | Fast: quick rise and fall times |

Power Consumption | Higher, less efficient | Lower, more energy-efficient |

Control Precision | Limited | High |

Efficiency Curve | Broad, less efficient | Sharp, higher efficiency |

LRA motors react faster and give sharper feedback. They use less power, so they save energy. This makes them good for things like phones and wearables that need quick feedback. ERM motors are simple and cost less money. They work well if you do not need fast or exact feedback. You can use ERM motors in factories where price and long life are more important than speed.

Tip: If you want a motor that lasts a long time and is easy to use, ERM motors are a good pick. If you need fast and sharp feedback with better energy use, LRA motors might be better.

Choosing the Right Motor

You may wonder how to pick the best vibration motor for your project. First, think about what matters most: speed, control, price, or how long it lasts. Using design thinking helps you balance what the device needs, how it feels to use, and how much it costs. You and your team can test different motors to see which one works best.

Try these steps to help you choose:

Write down what you need most: fast feedback, low power, or long life.

Test both ERM and LRA motors in your device.

Measure how strong, fast, and efficient the vibration is.

Ask users how the feedback feels to them.

Check how long each motor lasts in real use.

Some engineers use data to help make this choice. For example, you can collect vibration data from your device and compare how each motor works. You can also use models to guess which motor will last longer or use less power. This helps you pick the best motor, especially for medical or factory devices where long life and steady feedback are important.

Note: Always pick a motor that fits your device. If you need strong feedback for many years, focus on long life and strength. If you want fast, sharp feedback, look for high performance and good energy use.

You now know how ERM vibration motors work and where you can use them. When you choose a motor, you should check its lifespan to make sure it fits your project. A longer lifespan means your device will last longer and need less repair. If you want to learn more about vibration motors or compare lifespan across models, you can read product datasheets or ask experts for advice.

FAQ

How do you connect an ERM vibration motor to a battery?

You connect the red wire to the positive side of the battery. You connect the black wire to the negative side. The motor starts vibrating as soon as you complete the circuit.

Can you control the vibration strength?

Yes! You change the vibration strength by adjusting the voltage. Use a variable power supply or a simple circuit with a potentiometer. Higher voltage makes the motor shake more.

What should you do if your vibration motor stops working?

First, check the battery or power source. Make sure the wires are connected well. If the motor still does not work, try a new motor. Sometimes motors wear out after many uses.

Where should you place a vibration motor for the best effect?

You get the best results when you attach the motor to a firm surface close to where you want the vibration felt. Use double-sided tape or a small mount. Test different spots to see what feels best.

See Also

Understanding Different Types And Uses Of Vibration Motors

The Function Of Vibration Motors In Haptic Feedback

Vibration Motor Uses Across Various Modern Industrial Sectors

Advantages And Limitations Of 12V Vibration Motors Explained

Comprehensive Overview Of Vibration Motors And How To Choose

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry