Understanding ERM Vibration Motor RPM: Key Factors and Applications

You encounter ERM vibration motors in many everyday devices, from fitness trackers to medical equipment. In these motors, an offset mass rotates on a shaft, creating a strong vibration through centrifugal force. The speed of this rotation, known as RPM, plays a crucial role in determining how powerful and noticeable the vibration feels. When you understand how RPM affects vibration strength, you can make better choices for your application and enhance the user experience.

Key Takeaways

RPM, or revolutions per minute, directly affects the strength of vibration in ERM motors. Higher RPM means stronger vibrations, which is crucial for applications like wearables and industrial tools.

Choosing the right voltage is essential. Higher voltage increases RPM and vibration strength, but using too much can lead to overheating and reduced motor lifespan.

Understanding load and resistance is key. Adding weight or resistance can slow down the motor, reducing efficiency and vibration strength.

Motor design impacts performance. Features like the size of the eccentric mass and operating voltage influence RPM and vibration amplitude.

Custom solutions from INEED allow you to tailor vibration motors to your specific needs, ensuring optimal performance and reliability in your applications.

ERM Vibration Motor RPM

What Is RPM

RPM stands for revolutions per minute. It tells you how many times the shaft of a motor spins in one minute. When you look at an ERM vibration motor, the RPM shows how fast the offset mass rotates. This speed creates the vibration you feel in devices like fitness trackers or medical sensors. You can measure RPM by counting the number of complete turns the shaft makes every minute. For example:

RPM shows the number of full rotations per minute.

A 3V DC ERM motor can reach up to 12,000 RPM, depending on its design and the weight of the offset mass.

The input voltage affects RPM. Higher voltage usually means higher RPM and stronger vibration.

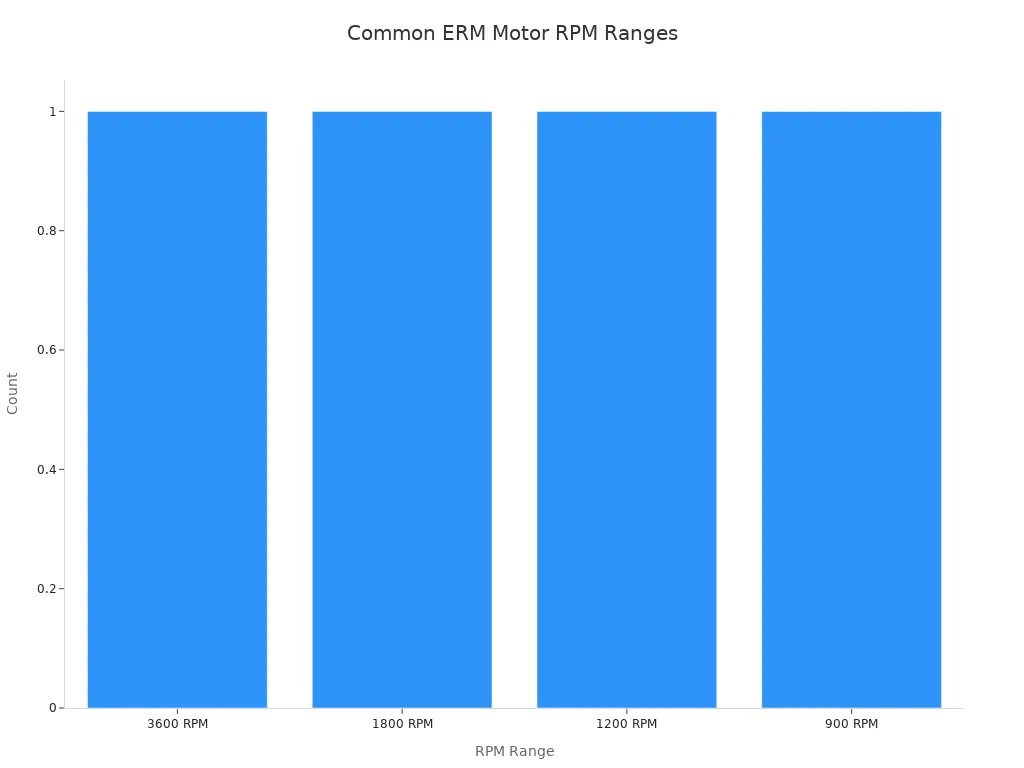

You can see the most common RPM ranges for ERM vibration motors in commercial use in the table below:

RPM Range | Motor Type | Voltage | Phase | Notes |

|---|---|---|---|---|

3600 RPM | 2-Pole | 230/460 | 3 | Ideal for bins, hoppers, and chutes |

1800 RPM | 4-Pole | 230/460 | 3 | For vibrating tables, feeders, and screens |

1200 RPM | 6-Pole | 230/460 | 3 | For large feeders and vibratory screens |

900 RPM | 8-Pole | 230/460 | 3 | Shakeout vibrator for foundries |

Why RPM Matters

You need to understand why RPM is important when you choose an ERM vibration motor. The RPM directly affects how strong and noticeable the vibration feels. If you want a gentle alert in a wearable, you might pick a lower RPM. For industrial equipment that needs powerful shaking, you would select a higher RPM. RPM also influences how efficiently the motor uses energy and how long it lasts.

Researchers have used ERM vibration motors in many fields. For example, scientists designed a robotic system that moves on sand using ERM motors. Medical engineers use these motors in capsule endoscopy to create controlled vibration patterns. Wearable technology often relies on ERM motors to give you haptic feedback, making devices more interactive.

Engineers face several challenges when they try to optimize RPM:

Keeping RPM accurate and repeatable, especially when the motor runs for a long time.

Balancing performance, reliability, and cost.

Testing new materials and designs to improve vibration.

Making sure all parts work well together in the final product.

When you understand RPM, you can make better choices for your application. You get the right balance of vibration strength, efficiency, and reliability.

Factors Affecting ERM Vibration Motors

When you select an ERM vibration motor, you need to know why certain factors influence its RPM and overall vibration performance. Each factor plays a role in how the motor delivers vibration, amplitude, and power. Understanding these factors helps you choose the right vibration motors for your application and ensures reliable operation.

Voltage and Power

Voltage and power directly affect the speed and strength of ERM vibration motors. When you increase the voltage, the motor spins faster, which raises the RPM and makes the vibration stronger. You can see the most common voltage ratings for ERM vibration motors in commercial products in the table below:

Voltage Rating | Power Rating |

|---|---|

3V | Varies |

4.5V | Varies |

5V | Varies |

Higher voltage means more energy for the motor, which increases amplitude and vibration force. If you use the correct voltage, you get stable RPM and consistent vibration. If you use too much voltage, you risk overheating and reduced lifespan. INEED offers vibration motors with optimized voltage and power ratings, so you can match the motor to your device’s requirements.

Tip: Always check the recommended voltage for your ERM vibration motor. Using the right voltage ensures efficient power use and stable vibration.

Load and Resistance

Load and resistance change how ERM vibration motors perform. When you add more load or resistance, the motor needs extra power to keep vibrating at the same RPM. This can lower efficiency and create more heat. You might notice that heavy loads or increased resistance cause the motor to slow down, which reduces amplitude and vibration strength.

Increasing load or resistance requires the motor to exert more energy to maintain vibration, which can lead to decreased efficiency and increased heat generation.

Changes in load directly impact the motor's performance, as additional weight or resistance necessitates more energy for vibration.

You can see how different load conditions affect the lifespan and reliability of ERM vibration motors in the table below:

Load Condition | Observations | Impact on Lifespan |

|---|---|---|

180 hours | Motor enters "burnout" stage | Vibration force decreases, current increases, instability grows |

220 hours | Motor stops working | Failure due to broken brushes or metal dust covering commutator surface |

Extreme vibrations can cause fatigue in structural components. Imbalances in the motor can lead to loosened connections and accelerated wear on bearings. Misalignment of rotor and stator may occur over time, leading to potential catastrophic failure. The primary failure mechanism in ERM vibration motors is the degradation of internal precious metal brushes. As these brushes wear down, they fill the gaps in the commutator, leading to short circuits or brush fatigue, ultimately resulting in a permanent failure to operate.

INEED customizes vibration motors to handle different loads and resistance levels. You get motors that last longer and perform reliably, even in demanding environments.

Motor Design

Motor design shapes how ERM vibration motors deliver vibration and amplitude. When you look at the design, you see several features that influence RPM performance:

The size of the eccentric mass affects the force generated by the motor, influencing RPM performance.

The operating voltage determines the speed of the motor, which is directly related to RPM.

The motor speed is crucial as it dictates the vibration frequency and amplitude, both of which are essential for RPM performance.

If you choose a motor with a larger eccentric mass, you get stronger vibration and higher amplitude. If you select a motor with a compact design, you can fit it into smaller devices without losing performance. INEED offers a wide range of vibration motors, including coin vibration motors and encapsulated vibration motors, with customizable design features. You can select the right size, mass, and configuration to match your application.

Note: Custom motor design lets you optimize vibration strength, amplitude, and power for your specific needs.

Control Methods

Control methods determine how you manage the RPM and vibration output of ERM vibration motors. You can use analog or digital control systems. Each method has advantages and disadvantages, as shown in the table below:

Control Method | Advantages | Disadvantages |

|---|---|---|

Analog | Continuous signal processing, Lower latency | Susceptibility to noise, Drift and calibration issues, Limited flexibility |

Digital | High precision, Noise immunity, Flexibility | Complexity and cost, Latency and sampling issues, Dependency on power supply |

Analog control gives you smooth and immediate changes in vibration amplitude and RPM. Digital control offers precise adjustments and better noise immunity. If you need flexible vibration patterns, digital control works best. INEED supports both analog and digital control options, so you can choose the system that fits your device and application.

When you understand why voltage, load, motor design, and control methods matter, you can select ERM vibration motors that deliver the right vibration, amplitude, and power for your project. INEED’s expertise in customizing vibration motors ensures you get reliable performance and long-lasting operation, no matter your requirements.

Vibration Performance and RPM

Vibration Strength

You need to know why RPM changes the vibration strength in an ERM vibration motor. When the motor spins faster, the offset mass creates stronger vibration. This happens because higher RPM increases the frequency and force of the vibration. For example, if you look at the relationship between vibration frequency and motor speed, you see:

Vibration Frequency (Hz) | Motor Speed (RPM) |

|---|---|

100 | 6000 |

You might think higher RPM always means stronger vibration, but that is not always true. At 1121 RPM, the vibration values can be higher than at 1479 RPM. This shows that the design of the motor and the load also affect vibration amplitude. INEED’s coin vibration motors use this principle to deliver precise haptic feedback in wearables and medical devices. You get reliable vibration strength because the motors are tested with accelerometers and mounted securely for accurate results.

Efficiency

You want your vibration motors to use power wisely. Efficiency tells you how well the motor turns electrical power into mechanical vibration. When you choose the right RPM, you get strong vibration without wasting energy. If the RPM is too high, the motor may use more power and create extra heat. If it is too low, you may not get enough vibration for your application. INEED’s encapsulated vibration motors are designed for high efficiency. They use coreless designs and strong housing to keep power use low and vibration output high. You can trust these motors to run longer and stay cool, even in tough environments.

Suitability for Applications

You need to match the RPM and vibration performance to your specific task. Accurate RPM helps you analyze vibration and avoid errors in your device. If you use the wrong RPM, you might misidentify faults or miss important signals. For example:

Accurate RPM is essential for effective vibration analysis.

Errors in RPM can affect the calculation of higher harmonics.

Understanding the link between frequency and RPM helps you keep your machinery healthy.

INEED offers a wide range of vibration motors, including coin and encapsulated types, so you can pick the best motor for your needs. You get motors that fit small wearables, medical devices, or industrial tools. Each motor is tested with known weights and suspended setups to measure vibration amplitude and ensure reliable performance.

Tip: Always check the RPM and vibration specs before choosing a motor. This helps you get the right power, efficiency, and vibration for your project.

Applications of ERM Vibration Motors

Wearables and Medical Devices

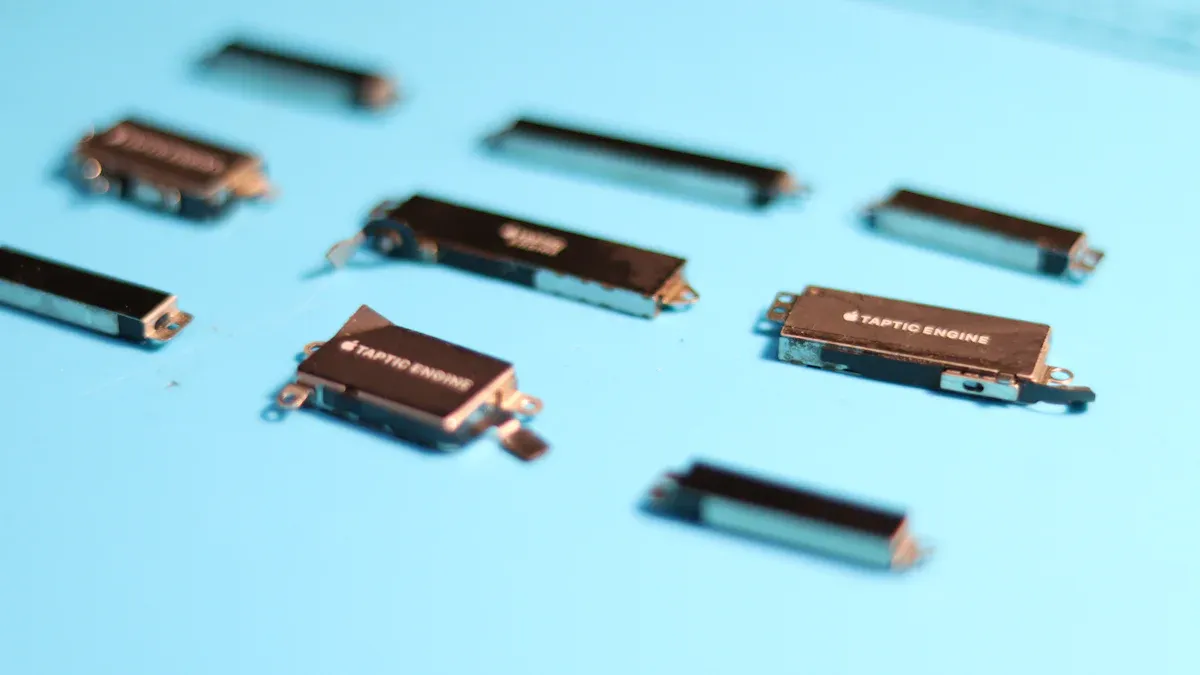

You see ERM vibration motors in many wearable and medical devices because they deliver reliable vibration feedback. Why do designers choose these motors? You need vibration to alert users, provide haptic feedback, or support therapy. In wearable technology, you feel a gentle buzz when you get a call or message. Medical devices use vibration to guide users during surgery training or to warn about health issues. Massage chairs and therapy tools use vibration to relax muscles and ease pain.

In healthcare, vibration helps with surgery training and health alerts.

In wearables, vibration notifies you about calls, messages, and health updates.

Therapy tools use vibration to improve comfort and recovery.

Brushed ERM motors in these applications usually run between 30Hz and 500Hz. This range gives you the right balance of vibration strength and comfort. You must consider factors like eccentric mass, shaft, bearings, housing, power connections, and environmental conditions. The table below shows why each factor matters:

Factor | Importance |

|---|---|

Eccentric Mass | Controls vibration intensity and quality. |

Motor Shaft | Transfers motion; must last through repeated use. |

Bearings | Keep vibration smooth; need regular care. |

Housing | Supports and cools the motor; helps transmit vibration. |

Power Connections | Ensure steady vibration; need regular checks. |

Environmental Factors | Affect motor performance; must match device conditions. |

Consumer Electronics

You rely on vibration in consumer electronics for a better user experience. Why does RPM matter here? The right RPM ensures you feel every alert, tap, or notification. Devices like smartphones, fitness trackers, and smartwatches use ERM vibration motors to create tactile feedback. You notice the difference when the vibration is too weak or too strong. Designers select RPM based on how noticeable and comfortable the vibration should be. Lower RPM gives a softer feel, while higher RPM creates a stronger buzz. INEED offers coin vibration motors that fit into slim devices and deliver consistent vibration, making your interactions more engaging.

Industrial Uses

You find ERM vibration motors in many industrial applications because they provide powerful and reliable vibration. Why do you need specific RPMs in these settings? Industrial equipment often requires strong vibration to move materials, alert workers, or test products. For example, the C1027BTF03 model from INEED runs at 9000 RPM and works well in harsh environments. You can mount these motors on PCBs or housings using self-adhesive tape. Industrial uses include vibrating tables, feeders, and screens. You must select the right RPM to match the task—higher RPM for rapid movement, lower RPM for gentle shaking. This choice ensures the motor delivers the right vibration for each industrial need.

Tip: Always match the RPM of your ERM vibration motor to the specific requirements of your application. This ensures you get the best performance and longest motor life.

Choosing RPM for INEED Vibration Motors

Assessing Needs

You need to start by understanding why your application requires a specific vibration level. The right RPM for your ERM vibration motors depends on the type of feedback or alert you want to deliver. If you use a wearable device, you want a gentle vibration that does not disturb the user. For industrial tools, you may need a stronger vibration to ensure clear signals. You must consider how they work and the role of the eccentric rotating mass principle. This principle explains why the offset mass creates vibration when the motor spins. You also need to think about the power available in your device and how much space you have for the motor.

Tip: Always measure the vibration strength you need before choosing a motor. This helps you avoid over- or under-powered solutions.

Matching RPM to Application

You must match the RPM to your application to get the best performance. The eccentric rotating mass principle means that higher RPM creates stronger vibration, but too much can reduce comfort or cause wear. You should look at the frequency and amplitude needed for your device. For example, medical devices often require precise, low-level vibration, while consumer electronics may need a quick, noticeable buzz. You can use peak amplitude, frequency spectra, and power spectral density to compare options. These metrics help you understand how the motor will perform in real-world use.

Customization Aspect | Details |

|---|---|

Electrical Performance | Rated voltage, rated current, speed, vibration, torque, etc. |

Physical Characteristics | Customized wire length, adding connectors, customized FPC available. |

Custom Solutions from INEED

You may wonder why you should choose a custom vibration motor from INEED. The answer lies in the flexibility and support you receive. INEED offers a wide range of customization options for ERM vibration motors, including electrical performance and physical characteristics. You can request changes to wire length, connectors, or even the motor’s speed. INEED also provides technical support to help you understand controlling vibration and the importance of grms in vibration testing. This support helps you set safe limits and ensures your motor lasts longer.

INEED guides you through the selection process.

You get help with vibration testing and understanding grms levels.

You receive advice on safe design limits for your motor.

When you work with INEED, you gain access to expert advice and tailored solutions. This ensures your motor fits your needs and delivers reliable performance in any application.

Understanding why RPM matters in an erm vibration motor helps you achieve the right balance of vibration strength and device performance. You can see the impact of RPM in several ways:

Higher voltage increases RPM, which creates stronger vibrations.

You can calculate vibration frequency by dividing RPM by 60.

Adjusting voltage or duty cycle lets you control vibration feedback for each application.

INEED gives you expert support and custom solutions, so you always find the best motor for your needs. For reliable advice and tailored vibration motor options, reach out to INEED.

FAQ

Why should you care about the RPM of an ERM vibration motor?

You should care because RPM controls how strong and noticeable the vibration feels. The right RPM helps your device deliver the best feedback, whether you want a gentle alert or a powerful shake.

Why do different applications require different RPM settings?

Different devices need different vibration strengths. For example, a fitness tracker needs a soft buzz, while industrial equipment needs a strong vibration. Matching RPM to your application ensures the best performance and user experience.

Why does INEED offer custom RPM options for vibration motors?

You get custom RPM options so your device can meet specific needs. Customization lets you choose the right vibration strength, efficiency, and size for your project. This helps your product stand out in the market.

Why is RPM important in the automotive industry?

RPM matters in the automotive industry because precise vibration feedback can improve safety and comfort. For example, haptic alerts in steering wheels or seats help drivers stay aware without distraction.

Why do you need to test vibration motors before final installation?

Testing ensures the motor delivers the right vibration and works reliably in your device. You can catch issues early, avoid costly mistakes, and make sure your product meets quality standards.

See Also

Exploring Motor Diagrams: Types, Parts, and Uses in ERM

Battery-Powered Motors: Varieties, Uses, and Efficiency Tips for ERM

Choosing the Perfect ERM Vibrator Motor in 8 Simple Steps

Understanding Motor Diagrams: Key Parts and Their Roles in ERM

Motor Brush Diagrams: Key Elements for ERM Motor Efficiency and Care

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry