Emerging Trends Shaping Vibration Motor Technology in 2025

Motor technology in 2025 is changing very fast. Tech trends like miniaturization, advanced piezoelectric materials, and AI-driven control help this change. Cars and smart devices now need motors that work well, last long, and can adapt. The market could be worth USD 10,253 million. This is because of new ideas in vehicle electrification and green manufacturing. These trends make motor technology follow tougher environmental rules. They also help new uses in cars, factories, and electronics. Companies need to use these new ideas to stay ahead of others.

Key Takeaways

Miniaturization makes vibration motors smaller and more accurate. This helps make better wearables, medical tools, and smart devices.

Smart technologies like AI and IoT make motors work better. They let people check motors from far away. They also help fix problems before they happen.

Energy-efficient designs and light materials help motors use less power. These things also help make products in a greener way.

Advanced vibration motors help healthcare in many ways. They help with therapy, watch health, and make patient care better.

Customization in cars and electronics gives users more choices. It helps people have better experiences and smarter devices.

Key Trends in Motor Technology

Miniaturization

Miniaturization is a big trend for motors in 2025. Engineers make motors smaller, lighter, and more exact. People want tiny devices for healthcare, robots, and electronics. Brushless DC motors, smart motors with AI, and wireless controls help this happen. New materials make motors stronger and save energy. This lets motors shrink but still work well.

Companies use piezoelectric materials to build squiggle motors. These motors are very accurate and very small.

Closed-loop feedback and AI maintenance make motors more reliable. This helps make smaller motors.

Asia-Pacific spends a lot on micro motor technology. This shows they support making motors smaller.

Brushless micro motors are used in medical devices. They last longer and work more precisely.

Miniaturization lets us have more wearables, better medical tools, and smarter robots. The small motor market could be worth over USD 22 billion by 2025. This shows people want these new small motors.

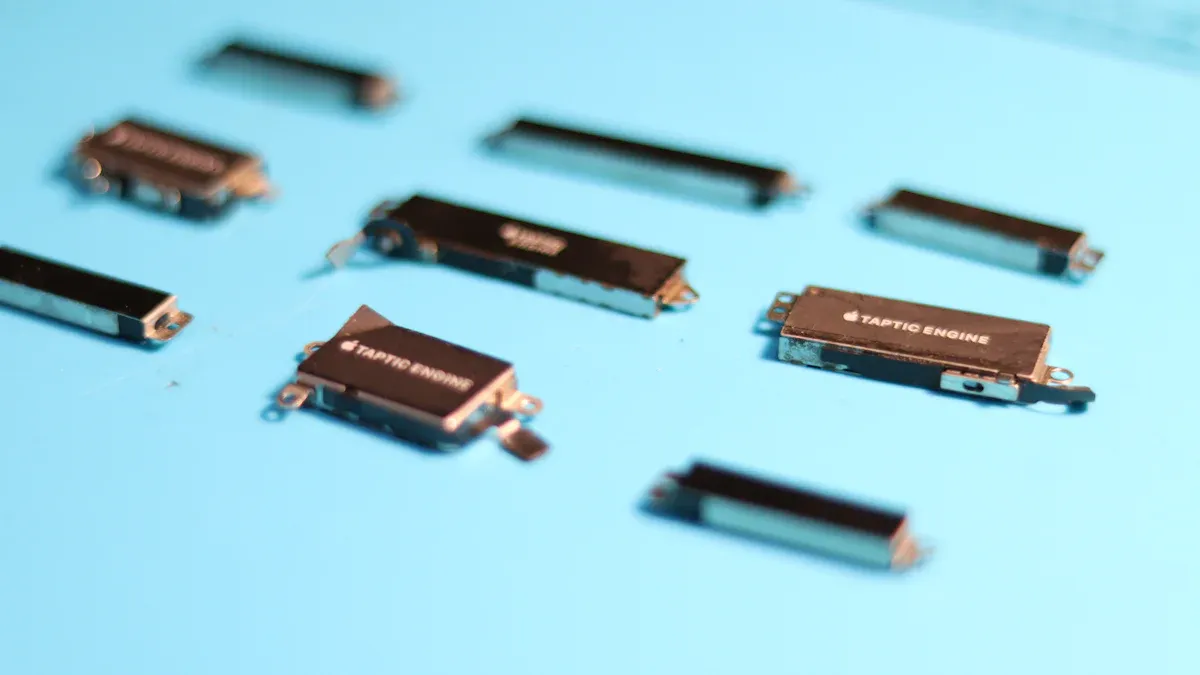

Micro-Motors in Wearables

Micro-motors are important in wearable tech. Their small size and accuracy add new features to smartwatches and fitness trackers. These motors give feedback you can feel, move things exactly, and stay quiet. The world market for micro motors will grow from USD 43.4 billion in 2023 to about USD 81.5 billion by 2033. This is because people want smaller gadgets.

New products like Maxon's flat DC micro motors show companies want power in small spaces. North America will see fast growth in this area. This is because of new health and smart device tech. Micro-motors in wearables help people track health, get alerts, and use devices in new ways.

Micro-motors help with:

Haptic feedback in smartwatches

Vibration alerts in fitness bands

Quiet use in medical wearables

Wearable devices use these trends to give users more personal and quick responses.

Medical Applications

Medical uses for advanced vibration motors keep growing. Hospitals and clinics use these motors in rehab, diabetes care, and pain relief devices. Vibration motors help with whole-body vibration therapy. This therapy helps bones, muscles, and metabolism.

Type of Vibration | Frequency | Amplitude | Clinical Implications |

|---|---|---|---|

Vertical | Low | Low | Rehab, better bone health |

Vertical | High | High | Helps with weight loss |

Vertical | Low | High | Better life for type 2 diabetes |

Vertical | High | Low | Better muscle activation |

Rotational | Low | Low | Helps neck pain or vertigo |

Rotational | Low | High | Less HbA1c, smaller waist, less fat |

Sonic Wave | Unknown | Unknown | Better balance and mood in elderly |

Studies show WBV helps insulin, blood sugar, balance, and life quality. Low-frequency, low-amplitude vibration is good for rehab and metabolism. High frequency and amplitude help with weight loss and muscles. Rotational vibration cuts fat and helps bones in people with metabolic syndrome.

More medical devices now use vibration motors. In the U.S., over 65% of vibration motors in 2024 are for custom industrial and medical devices. The market will grow about 9.7% from 2025 to 2032. This shows motor technology is very important in healthcare.

Medical devices now use advanced motors to help patients and support new treatments.

Electric Motor Tech Trends

Energy Efficiency

Energy efficiency is very important for new electric motors. Companies want to use less power and get more work done. New electromagnetic vibration energy harvesters help with this goal. These devices can make up to 3.83 mW at 31 Hz and 0.5 g acceleration. Gear racks and bevel gear sets change vibration into electricity. This way, they can reach 2.7 W of power. That is 66% more than old sine excitation methods.

Engineers pick strong materials like piezoelectric, magnetostrictive, and magnetoelectric compounds. These materials make motors last longer and work better.

MEMS technology helps make motors smaller and more efficient.

Multi-directional energy harvesting takes in vibrations from every direction. This gives more total energy.

Smart control systems help save energy and stop waste.

Variable frequency drives, or VFDs, are also very important. VFDs change motor speed and power use based on the job. This saves 5% to 15% energy most of the time. Some systems save up to 65%. VFDs also cut down on pollution and need less fixing.

Energy-efficient motors help companies spend less and follow new green rules. These trends help make motors smarter and better for the planet.

Battery Integration

Battery integration is changing vibration motor technology. Designers now make motors that work well with new battery systems. This helps devices run longer and work better. Engineers choose batteries that fit each motor’s needs. This stops energy waste and makes batteries last longer.

Smart battery systems watch charge levels and change motor power.

Fast-charging lets devices get ready quickly for important jobs.

Small battery designs fit into tiny devices but still give enough power.

Good battery systems help medical devices, wearables, and electric vehicles. These things need steady power and smart energy use. As batteries get better, motors also get more flexible and efficient.

Lightweight Materials

Lightweight materials are now very important for electric motors. Engineers use composites, advanced polymers, and light metals to make motors weigh less. This makes motors easier to install and saves energy.

Material Type | Benefit | Common Use Cases |

|---|---|---|

Carbon Fiber | High strength, low weight | Automotive, drones |

Aluminum Alloys | Good conductivity, light | Consumer electronics |

Advanced Polymers | Corrosion resistance | Medical devices |

Lighter motors use less energy to run. This matches the need for greener and better products. Devices with light motors last longer and work well in tough places.

Using lightweight materials helps make electric motors smaller and more efficient for many uses.

Smart Motor Technology

AI and Adaptive Control

AI is changing how vibration motors work in 2025. Artificial intelligence helps motors adjust how they run right away. Neural-adaptive controllers only use motor speed to get feedback. This means fewer sensors are needed, so systems cost less. These controllers fix hard problems like changes in two-mass drive systems. They use learning tools like fuzzy logic and backpropagation to change settings quickly. Because of this, vibration motors stay steady and work better than old controllers. Tests show these AI systems keep motors smooth, even if things change or problems happen. This makes vibration motors more reliable and efficient for many jobs.

AI-based adaptive control leads to fewer breakdowns and better results, even in tough places.

IoT and Connectivity

IoT-enabled vibration motors link devices and systems in new ways. Simple sensors check vibration and temperature, then send data to the cloud. Wireless connections let people check machines from anywhere. Platforms like Golioth help with strong data checks and remote access. Devices like the ioX-Connect Wireless Vibration Sensor and Memsio wireless MEMS accelerometer have long-range links, sense in many directions, and use batteries. These features help find problems early, plan fixes, and make equipment last longer. IoT also allows updates over the air and easy data sharing in smart factories and cars.

Key benefits:

Real-time checks

Early problem finding

Remote tests

Less downtime

Predictive Maintenance

Predictive maintenance uses smart sensors and data to keep motors working longer. Wireless vibration sensors watch equipment all the time, even in hard spots. IoT systems gather and study data to find problems before things break. AI and machine learning turn vibration data into simple tips, so teams can plan repairs and stop emergencies. Edge computing handles data on-site, so there are fewer delays and better safety. In oil and gas, predictive maintenance stops big outages and helps manage equipment.

Solution Type | Main Benefit | Impact |

|---|---|---|

Wireless Vibration Sensors | Real-time checks | Less manual work, longer equipment life |

IoT Condition Monitoring | Remote health checks | Early alerts, fewer breakdowns |

AI Analytics | Smart data study | Better reliability, fewer repairs |

Edge Computing | Fast, local data work | Quick tips, better safety |

Predictive maintenance saves money, cuts downtime, and keeps equipment working well.

Customization and Industry Solutions

Automotive Innovations

The car industry is making vibration motors fit new cars. Companies now work on software-defined vehicles and battery electric vehicles. Stellantis made the Dodge Charger SRT Concept EV. It has a software-controlled sound and vibration system called the “Fratzonic Chambered Exhaust.” Drivers can change the sound and vibration or turn it off for quiet places. Ford and BMW also use software to make engine-like sounds and special audio. These new ideas use software to copy vibration and sound. This makes driving feel better without changing the hardware. Car companies use this to help with electric cars and self-driving features. Drivers get a fun and changeable experience.

Stellantis: Fratzonic Chambered Exhaust lets you change vibration and sound

Ford and BMW: Use software to make engine sounds

Focus: Software feedback helps electric and self-driving cars

Customization in car technology gives drivers more fun and choices.

Consumer Electronics

Consumer electronics use new vibration motors to make devices better. Phones, tablets, and game controllers use two main motor types: Eccentric Rotation Mass (ERM) and Linear Resonant Actuator (LRA). ERM motors spin an off-center weight. LRA motors move back and forth for exact feedback. These motors make touchscreens easier and more fun to use. Haptic feedback in games and displays feels more real and keeps users interested. New trends are making motors smaller, smarter with IoT, and saving energy. Better materials make motors lighter and stronger.

Motor Type | Key Feature | Application |

|---|---|---|

Spinning weight | Phones, wearables | |

Moves back and forth | Gaming, tablets |

Vibration motor technology connects digital and real life, making devices more fun to use.

Healthcare Devices

Healthcare devices use special vibration motors to help patients. Vibration therapy sends gentle shakes to skin and muscles. This helps muscles move, balance, and walk better, especially for people with nerve problems. Wearable health devices now use AI to watch and study data in real time. These devices use vibration motors for therapy and checking health. Smart canes with sensors and vibration help people walk safer. AI looks at the data to find health risks and make treatments fit each person. This helps doctors act early and give better care.

Wearables: Watch health and give feedback right away

Smart canes: Help people walk better and safer

AI: Finds problems early and helps doctors work together

New ideas in healthcare devices make care smarter, faster, and focused on the patient.

Sustainability Trends

Eco-Friendly Materials

Manufacturers pick materials that are better for the earth. They use plastics that can be recycled and polymers that break down. Some metals they use do not hurt the environment. These choices help cut down on trash and pollution. Many companies make motors with parts that are light and strong. This helps motors last longer and use less power. Some factories use plastics from plants for motor covers. Others choose metals that can be recycled over and over. These actions help keep the planet clean and help companies follow strict rules.

Using eco-friendly materials in vibration motors means less trash and a smaller carbon footprint.

Energy-Saving Features

Energy-saving features are now common in new vibration motors. Smart sensors and control systems help motors use just the power they need. This cuts down on wasted energy and saves money. Some motors have systems that catch and reuse power. Others turn off by themselves when not needed. These features help devices last longer on one battery. They also help electric cars and portable devices work better.

Feature | Benefit |

|---|---|

Smart sensors | Use less energy |

Energy recovery | Use power again |

Auto shut-off | Save battery life |

Green Manufacturing

Green manufacturing is now very important for vibration motors. Companies try to make less waste and save energy. They use clean ways to make things. They follow strict recycling rules and use lean methods to use fewer materials. Many factories use solar panels and machines that save energy. Special services like vibration checks and predictive maintenance help control noise and energy use. These steps make products better and keep workers safe. Most companies want ISO 9001 and ISO 14001 certifications to show they care about the earth and quality. These standards prove a company works to protect the planet.

Green manufacturing helps the earth by cutting pollution and making better products.

Future Outlook

Evolving Trends

Experts think many new trends will change vibration motor technology soon. Companies will use IoT sensors to watch motors in real time. This helps them fix problems before things break. More factories will use machines to test vibration. These machines make tests faster and more correct. Artificial intelligence and machine learning will study lots of data. They will help find weak spots and set up better tests. Manufacturers will use more electrodynamic shakers. These shakers can test many different speeds and strengths. By using environmental chambers, tests can copy both shaking and weather changes. Engineers can watch data live and change tests from far away. New rules, especially for cars, will make companies use testing systems that can be changed and built in parts.

Experts say that using IoT sensors and AI will make vibration motors smarter, safer, and more dependable in many fields.

Impact on Manufacturers

Manufacturers have new problems and chances as vibration motor technology changes. They need to make motors that save energy, are small, and are good for the earth. More people want smart devices, electric cars, and new ways to move. This makes companies create special products. Many manufacturers now work together, make new products, and focus on what customers want. High prices and other motor types like piezoelectric motors mean companies must watch costs and keep inventing. Local things, like spending on green tech and factory growth, also change how companies make things. The need for better ways to make things and custom products keeps growing as more cars, electronics, and factories use these motors.

Manufacturers use:

Better ways to make things

Teamwork with other companies

Always working to make products better

End-User Benefits

People who use vibration motors get many good things from new technology.

Workplaces like factories, oil and gas, and planes are safer and more productive

Predictive maintenance means less fixing and fewer stops

It is easier to follow safety and green rules

Workers feel better and machines last longer

Small motors fit in tiny devices like health wearables and electronics

IoT and automation let people control and adjust motors from far away

Better haptic feedback in cars and games makes them more fun to use

Motors last longer and cost less to run

Motors can be used in more ways, helping new cars and ways to travel

These new features help users work better, stay safe, and enjoy their devices at home and at work.

Vibration motor technology in 2025 is changing a lot. Miniaturization, smart features, and being eco-friendly are important.

Micro AC motors work well in small spaces and are strong. They help many industries give users a better experience.

IoT and predictive maintenance make things run smoother and stop long breaks.

Manufacturers use modular designs, green materials, and team up with others.

End-users get more value by watching devices from far away and using vibration analysis with other tools.

New ideas and saving energy will help both makers and users stay ahead in a fast-moving market.

FAQ

What industries benefit most from new vibration motor technology?

Many industries get help from new vibration motor technology. The top ones are automotive, healthcare, and consumer electronics. These groups use advanced motors to make products work better and last longer. They also give users a better experience.

How does AI improve vibration motor performance?

AI lets motors change how they work right away. It looks at data to set the best speed and stop mistakes. This means motors break less and last longer. Companies use AI to make their systems smarter and more efficient.

Why is miniaturization important for vibration motors?

Miniaturization helps engineers put motors in smaller things. Wearables, medical tools, and smart gadgets need tiny motors. Small motors save space, use less power, and let people make new designs.

What makes a vibration motor eco-friendly?

Eco-friendly motors use materials that can be recycled. They also have features that save energy. Makers pick light metals and plastics that break down. These choices make less trash and help the planet.

Can predictive maintenance reduce downtime?

Yes. Predictive maintenance uses sensors and data to find problems early. Teams can fix things before they break. This keeps machines working and saves money by stopping long delays.

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry