Electric Vibration Motor Maintenance: Extending Lifespan and Optimizing Performance

Taking care of your electric vibration motor is important. It keeps it working well and lasting longer. Checking and fixing it often saves money and avoids problems. Predictive care costs 40% less than fixing after it breaks. Many businesses save 30% on repairs and have 75% fewer issues. This also cuts downtime by 45%, making work smoother. By focusing on care, you get a reliable and cheaper system.

Key Takeaways

Taking care of motors often can make them last longer.

Good upkeep can cut breakdowns in half and keep work steady.

Using proper oil and checking wires stops expensive fixes.

Watching vibrations and heat finds problems early, saving cash and time.

Tools that predict issues can stop big problems and help motors work better.

Understanding Electric Vibration Motors

What Are Electric Vibration Motors?

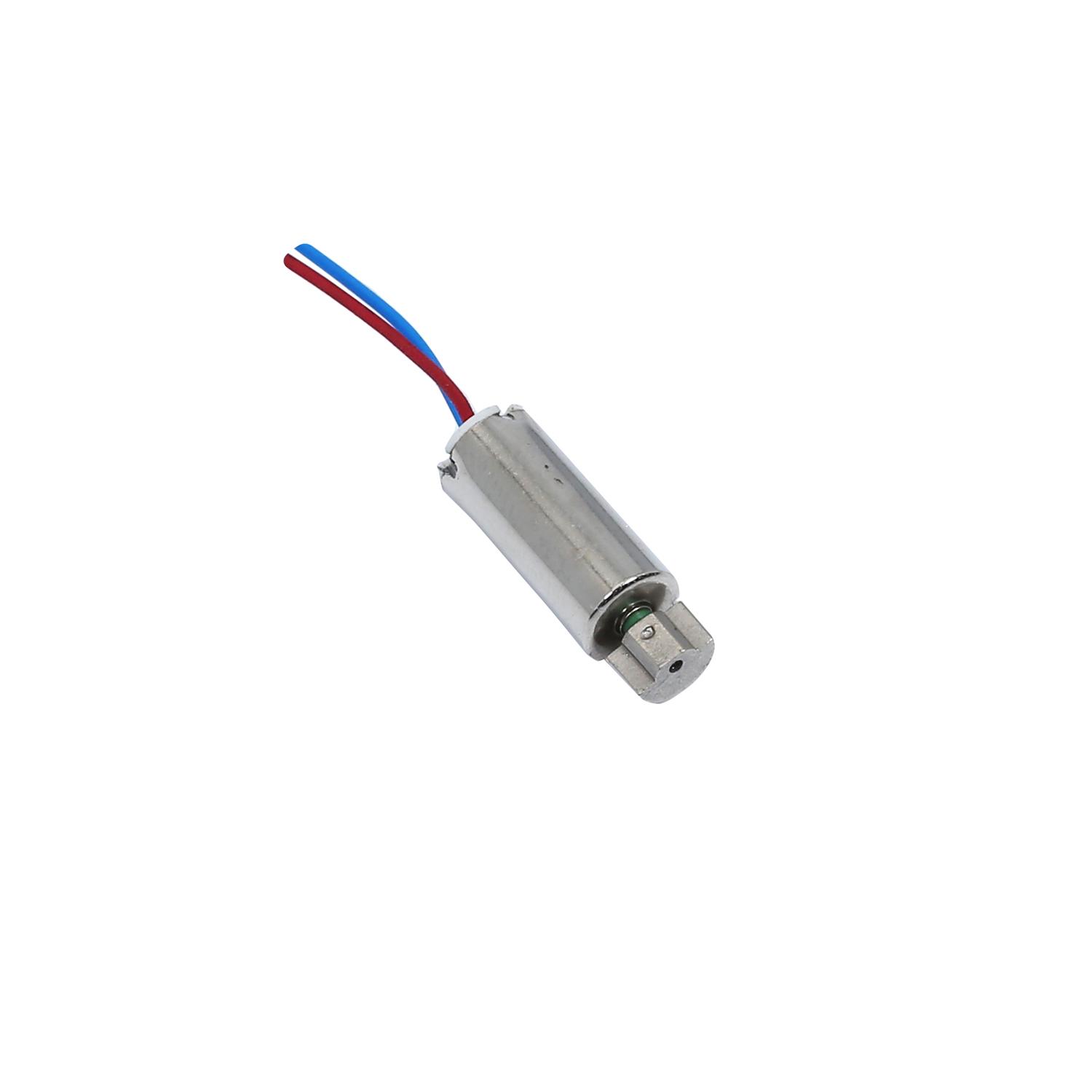

An electric vibration motor changes electrical power into shaking movements. These movements happen because of an uneven weight on the motor's shaft. When the motor spins, the uneven weight creates a force that makes it shake. This simple design works well for jobs needing controlled vibrations.

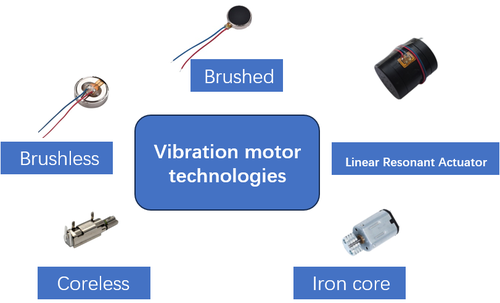

There are different kinds of electric vibration motors, like coin motors, linear resonant actuators (LRAs), and coreless motors. Each type has a special purpose. For example, coin motors are small and fit in tiny gadgets like smartwatches. LRAs give accurate feedback in phones. These motors are reliable and save energy, so they are used in many fields.

Applications of Electric Vibration Motors in Industries

Electric vibration motors are important in many industries. They are used in tools and systems where shaking is needed for work or user experience. Here are some examples:

Consumer Electronics: Phones and wearables use these motors for alerts and vibrations.

Healthcare: Medical tools use vibration motors to improve accuracy and ease of use.

Industrial Equipment: Machines like vibrating screens use these motors to sort materials better.

Retail: Barcode scanners use vibrations to show scans are successful.

Beauty Devices: Skincare tools use vibrations to clean skin more effectively.

These motors also save time and last longer in factories. For example, pumps with strong motor bases stay aligned, needing less fixing. Easy-to-take-apart designs make repairs faster and cheaper. By using electric vibration motors, industries get better performance and fewer problems.

Key Maintenance Practices for Electric Vibration Motors

Why Regular Maintenance and Inspections Matter

Taking care of your motor often keeps it working well. Regular checks help find problems before they get worse. For example, look for loose parts, wear, or misalignment. Fixing these early avoids big repairs or sudden breakdowns. A good maintenance plan makes your motor last longer and run smoothly.

Fun Fact: About 90% of motor failures happen due to poor care. Regular checks can lower these risks and make motors last longer.

Simple checks like looking at vibrations or parts can spot issues early. This helps your motor work better and use less energy. By caring for your motor regularly, you save time, money, and effort.

Lubrication to Reduce Friction

Lubrication is key to keeping your motor in good shape. It reduces friction between moving parts, helping them last longer. Without enough lubrication, parts like bearings can overheat or break. This can lead to expensive repairs.

Here are some easy tips for lubrication:

Use the right lubricant for your motor.

Don’t use too much or too little lubricant.

Check and add lubricant as part of your care routine.

These steps keep your motor running smoothly and prevent damage. Good lubrication improves performance and lowers the chance of sudden problems.

Watching Temperature for Better Performance

Temperature affects how well your motor works. High heat can damage parts and make the motor less efficient. Checking the temperature often helps catch overheating early.

Temperature sensors are helpful tools for tracking heat levels. They can show if insulation or other parts are failing. For example, when too hot, a motor might lose 30% of its power. This shows how heat can hurt performance.

Keep your motor in its safe temperature range for best results. Use temperature checks with vibration tests to find issues like damaged bearings. These steps help your motor work well, even in tough conditions.

Vibration Monitoring to Keep Motors Reliable

Watching vibrations helps your motor work well and last longer. It finds problems early, stopping big repairs and sudden stops. By checking how the motor shakes, you can spot issues like loose parts, worn bearings, or imbalance before they get worse.

Tip: Checking vibrations often keeps your motor strong and saves money.

New tools for vibration checks use smart technology to study motor health. These tools gather data all the time to find problems early. For example:

Smart systems use math methods like PCA and K-Means to find odd patterns.

AI tools, like CNN and LSTM, make problem-spotting more accurate.

Bearings make special vibration signals, which tools can study to predict issues.

By focusing on key vibration signals, you can plan fixes at the right time. This saves money and uses resources better. Watching vibrations all the time not only finds problems but also keeps your motor dependable.

Checking Electrical Connections for Smooth Running

Good electrical connections are key for your motor to work well. Loose or rusty connections can stop power flow, causing problems or even motor failure. Checking and fixing these connections often keeps your motor running smoothly.

Look for signs of damage, like burnt spots or broken wires. Tighten loose parts and replace bad ones quickly. Use a multimeter to check voltage and make sure power flows right. These simple steps stop big problems later.

Note: Bad electrical connections often cause motor troubles. Fixing them early keeps your motor working well.

For better checks, use advanced tools to test your motor. These tools measure things like resistance and insulation. They also find hidden problems that regular checks might miss. By mixing simple checks with smart tools, you can make your motor last longer and work its best.

Advanced Tips to Improve Electric Vibration Motor Performance

Keeping Alignment and Foundation Correct

Good alignment and a strong base help your motor work well. If the motor is not aligned, it can shake unevenly. This can damage parts and make the motor wear out faster. A weak base can make these problems worse, lowering the motor's efficiency and life.

To fix alignment, use special tools that measure accurately. The table below shows some helpful methods:

Technique | What It Does |

|---|---|

Ultrasound and Vibration Readings | Tracks alignment over time and gives data for checking. |

Alignment Tools | Shows numbers to check alignment, helping with better care. |

Easy-Laser XT190 | Gives real-time numbers for belt alignment, making fixes easier. |

These tools help find and fix alignment problems early. This stops extra stress on the motor and makes it work better. Also, make sure the motor's base is steady and not shaking from outside forces. A strong base keeps the motor running smoothly and efficiently.

Saving Bearings from Stray Currents

Stray currents can harm motor bearings and cost a lot to fix. Protect bearings by using ways to block or redirect these currents. Here are some tips:

Proper Grounding: Make sure the motor shaft is grounded to stop currents from harming bearings.

Insulated Bearings: Use bearings with special coatings to block electric currents.

Shaft Grounding Devices: Add devices like grounding rings to safely send stray currents to the ground.

These steps protect bearings and make the motor more reliable. Regular checks can find problems early. For example, grounding tests can show if these protections are working. By doing this, you can make your motor last longer and work better.

Picking the Right INEED Vibration Motor for Your Job

Choosing the right motor is important for good performance. INEED has many motors for different needs. Think about these factors when picking one:

Parameter | What It Means |

|---|---|

Peak | The strongest vibration over a certain time. |

RMS | The average vibration strength, showing the overall load. |

Crest Factor | Compares the strongest vibration to the average, showing performance changes. |

Check the motor's voltage and current needs. Most motors use 2 to 5 volts and need 50 to 100 milliamps. For battery devices, low-power motors like LRAs are best because they save energy. ERM motors are stronger but use more power.

Think about the environment too. Motors made for certain temperatures or with water protection work better in tough places. For hard jobs, brushless DC motors last longer and are more durable.

Noise is also important. Quiet motors are better for things like phones and wearables. Plastic motors make less noise than iron ones, so they are good for quiet jobs.

By looking at these factors, you can pick the best INEED motor for your needs. This helps your device work better and last longer.

Using Predictive Maintenance Tools for Better Motor Care

Predictive maintenance tools help keep motors working well. These tools use smart technology to check motor health and find problems early. They make motors last longer, cost less to fix, and work better.

The best part of predictive maintenance is spotting issues early. Sensors check vibrations, heat, and power in real time. If something unusual happens, like overheating, the system warns you. This helps fix small problems before they become big ones.

Here’s how these tools help your motors:

Benefit | What It Does |

|---|---|

Non-destructive testing | Checks motors without changing or damaging them. |

Boosts safety and reliability | Finds problems early, lowering risks and keeping motors stable. |

Spots wear early, so you can fix parts instead of replacing them. | |

Improves motor performance and lifespan | Keeps motors running smoothly by fixing imbalances and alignment issues. |

Reduces unexpected downtime | Tracks motor health constantly, so repairs happen before breakdowns. |

Helps plan better | Gives data to schedule repairs and use resources wisely. |

Ensures compliance | Regular checks meet rules and keep systems working properly. |

These tools also protect important parts like bearings. Bearings help motors run smoothly but wear out over time. Predictive tools can find early signs of damage, like odd vibrations or noises. Fixing these early saves money and keeps motors running well.

Another benefit is better repair planning. Instead of waiting for a breakdown, you can fix things during quiet times. For example, if a sensor finds a small misalignment, you can fix it during regular maintenance. This avoids sudden shutdowns.

Predictive tools also give detailed reports about motor health. These reports help you decide when to repair or replace parts. Over time, this lowers the chance of sudden failures and makes motors more reliable.

To get the best results, use predictive tools with regular checks and good lubrication. Together, these steps keep motors working their best. By using predictive tools, you save money and feel confident your motors are in great shape.

Benefits of Proactive Maintenance for Electric Vibration Motors

Saving Money with Fewer Repairs and Less Downtime

Taking care of your motor early saves money. Fixing small problems costs less than big repairs. Planning maintenance ahead avoids costly emergencies. Predictive care can cut costs by 25-30%. This happens because small issues are fixed before they grow.

Proactive care also reduces downtime. Broken motors can stop work and waste time. Regular checks keep motors running and prevent interruptions. This saves money and keeps your work moving smoothly. Planning ahead helps avoid sudden stops and costly delays.

Making INEED Motors More Reliable and Efficient

Regular care makes your motor more reliable. It helps the motor work its best for your needs. Checking performance shows where improvements are needed. Key performance indicators (KPIs) guide you to fix gaps in performance.

Proactive care stops unexpected breakdowns. Watching your motor’s condition helps catch problems early. This lowers energy use and keeps the motor running steadily. INEED motors, known for quality, work even better with regular care. Proper maintenance ensures they stay reliable and perform well.

Longer Life for Electric Vibration Motors

Caring for your motor helps it last longer. Lubrication reduces friction and overheating, which can damage parts. Checking your motor every six months finds problems early. This prevents serious damage and costly repairs. Vibration checks are also helpful. They find mechanical issues by studying how the motor shakes.

Preventive care saves money and improves efficiency. It reduces downtime and repair costs, making your motor last longer. A well-maintained motor works reliably for years. This makes it a smart and valuable investment.

Tip: Use regular checks, lubrication, and vibration tests to keep your motor working well and lasting longer.

Taking care of your electric vibration motors is very important. It helps them last longer, work better, and keeps the workplace safer.

Main Advantages:

Motors can last 20-40% longer.

Downtime can drop by up to 50%.

You can save 25-30% on costs.

Advantage | Improvement |

|---|---|

Better Reliability | 47% longer MTBF |

Higher Efficiency | 18-25% more productivity |

By following these steps, your motors will work their best. You’ll save both time and money. Start now to get the most out of your motors!

FAQ

How should you clean an electric vibration motor?

Use a soft, dry cloth to wipe off dust. Do not use water or strong chemicals, as they can harm the motor. For hard-to-remove dirt, use compressed air to clean tight spaces. Cleaning regularly helps your motor work better.

How often should you check your vibration motor?

Check your motor every three to six months. Look for loose parts, strange vibrations, or overheating. Regular checks find small problems early, saving money and making the motor last longer.

Can you use any type of lubricant for vibration motors?

No, always use the lubricant suggested by the motor maker. Using the wrong one can harm the motor or lower its performance. Read the manual for details and apply only a small amount to avoid overdoing it.

What are signs that a motor is misaligned?

Watch for uneven shaking, strange noises, or worn-out parts. Misalignment can also cause overheating or poor performance. Use alignment tools to check and fix the problem quickly to avoid more damage.

How do predictive maintenance tools help?

These tools check your motor’s health all the time. They measure vibrations, heat, and power. If something seems off, they warn you about possible issues. This lets you fix problems early, saving time and money.

See Also

Understanding Motor Brushes: Key Elements for ERM Motor Efficiency

Exploring Battery-Powered Motors: Varieties and Efficiency Tips

All You Need to Know About Vibration Motors and Their Uses

Choosing the Perfect Vibrating Motor for Your Needs

Seven Key Uses of Vibration Motors to Boost Production Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry