Electric Motor Types: DC, Brushless, Stepper, and Gear Motors

You have many options when picking electric motor types for your project. DC, Brushless, Stepper, and Gear motors each have special strengths. For example, brushless motors can go faster than 10,000 RPM. They give a lot of power and need less care. Stepper motors are great for exact moves, so they work well in robots. Gear motors give strong force at slow speeds, which is good for tough jobs. If you know how each motor is different, you can pick the best one for your needs. You might want to save money, get more power, or be more exact.

Key Takeaways

Brushless motors are quieter and last longer than brushed DC motors. They also need less care. This makes them good for fast and efficient projects.

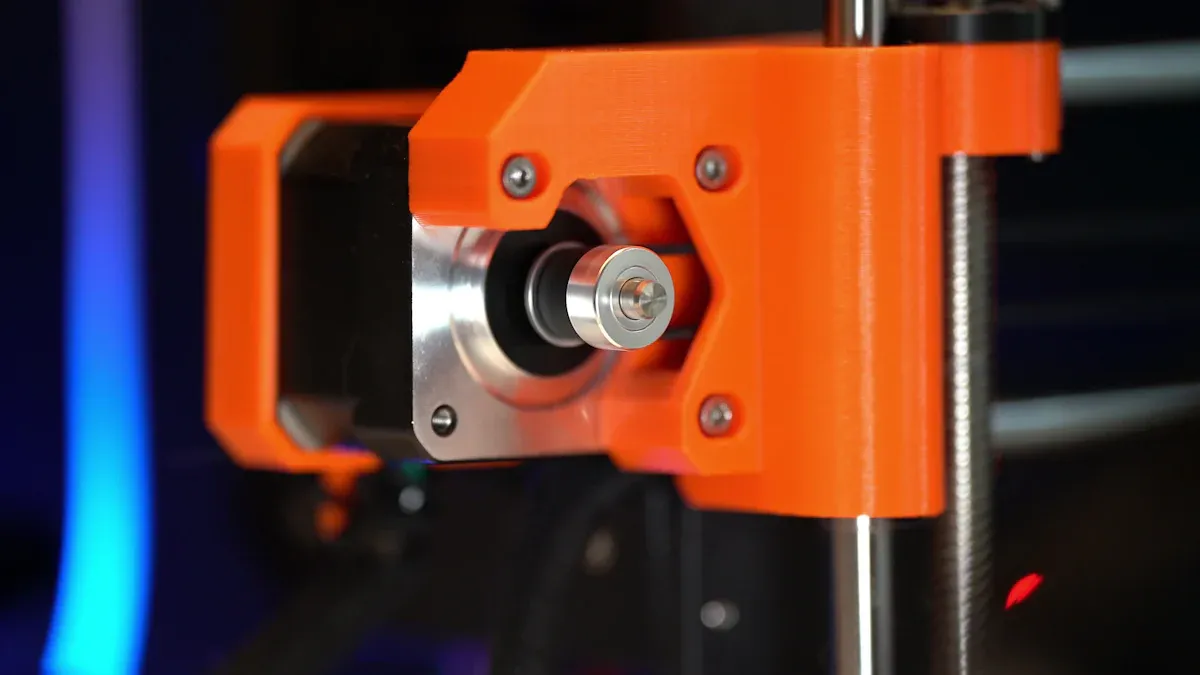

Stepper motors move in small, exact steps. They are great for projects that need very accurate control. 3D printers and robots use them a lot.

Gear motors make more torque at slow speeds. They help small motors lift or move heavy things. The motor does not have to be bigger.

Picking the right motor depends on what your project needs. Think about speed, power, accuracy, noise, and cost. This helps your project work better and last longer.

Check and match motor features like torque, speed, and control type often. This helps your machines run well and saves money over time.

Electric Motor Types Overview

Comparison Table

Picking the right electric motor can help your project work better. It can also save money and make things last longer. You should learn how each motor works. Each one has something special about it. The table below lets you compare DC, brushless, stepper, and gear motors. This helps you see which one is best for your needs.

Motor Type | Operation | Advantages | Disadvantages | Typical Uses |

|---|---|---|---|---|

DC Motor | Uses brushes and commutator for current flow | Simple control, low cost, fast response | Needs maintenance, shorter lifespan | Toys, fans, tools, car accessories |

Brushless DC Motor | Electronic commutation, no brushes | High efficiency, quiet, long lifespan | Complex control, higher initial cost | Drones, electric vehicles, HVAC |

Stepper Motor | Moves in steps with precise pulse control | High accuracy, easy position control | Less efficient, can be noisy | 3D printers, robotics, CNC machines |

Gear Motor | Combines a motor with gears for more torque | High torque at low speed, compact size | Lower speed, added mechanical parts | Lifts, conveyor belts, door openers |

Tip: Brushless DC motors are quiet and smooth. Stepper motors are good if you need exact moves.

Key Features

There are many electric motor types because each one does something special. DC motors are easy to control and react fast. This is good when you want quick and simple action. Brushless motors last a long time and do not make much noise. You will not need to fix them as often. Stepper motors move in tiny steps. This is great for machines that need to be very exact. Gear motors give more power to lift or move heavy things. You do not need a bigger motor for this.

Think about what is most important for your project. Do you want high speed, quiet sound, or more power in a small space? Knowing what each motor can do helps you choose the right one. This can stop problems later. That is why it is important to learn about electric motor types if you work with machines or electronics.

DC Motors

Brushed DC

Brushed dc motors are good if you want easy control. They use brushes and a commutator to change current direction. This makes it simple to change speed or direction. You often see brushed dc motors in toys and small tools. They are also in car accessories because they are cheap and work for simple jobs. But the brushes wear out after some time. You will need to replace them. This makes the motor noisy and shortens its life.

Brushless DC

Brushless motors fix many problems of brushed dc motors. They use electronics instead of brushes to switch current. This means less noise and less wear. They also last much longer. Brushless dc motors can work for over 10,000 hours. Brushed dc motors may only last about 3,000 hours. You find brushless motors in drones and electric cars. They are also in high-end fans. These motors give better speed control and more torque. They are also more efficient.

Feature | Brushed DC Motors | Brushless DC Motors |

|---|---|---|

Structural Design | Has brushes and a commutator that wear out | Uses electronics, no brushes |

Lifespan | Lasts 1,000–3,000 hours | Lasts 10,000–20,000+ hours |

Efficiency | 75–80% efficient | 85–90% efficient |

Speed & Acceleration | Brushes limit speed | Fast and precise with electronics |

Noise Generation | Makes more noise | Very quiet |

Maintenance | Needs brush changes often | Needs almost no maintenance |

Cost | Cheaper at first, but costs more to keep up | Costs more at first, but less to keep up |

Operation

You can control dc motors by changing the voltage. You can also use pulse width modulation (PWM). This helps you set the speed and direction. Brushed dc motors use brushes to switch current. Brushless motors use sensors and electronics. Brushless dc motors react faster. They also give better speed and torque control. You can check how well they work by looking at speed, current, voltage, and torque. For example, a brushed dc motor can go up to 9,000 rpm at 81% efficiency. Brushless motors can go even faster and use less energy.

Advantages

Why pick dc motors?

They have high starting torque to move heavy things.

They keep strong torque at many speeds, so machines run smooth.

You can control speed, position, and torque very well.

They react fast, so you can start or stop quickly.

Brushless motors last longer and need less care, which saves money.

Tip: Checking your dc motors often helps them last longer and work better.

Applications

Dc motors are used in many places because they are reliable. Brushed dc motors are in toys, small machines, and car windows. Brushless dc motors are in drones, electric cars, and robots. They last longer and need less care. In cleanrooms, brushless motors help keep the air clean. Dc motors are also in conveyor belts, lifts, and adjustable desks. They give strong torque and good control, so people use them for many projects.

Stepper Motors

Stepper Basics

Stepper motors are popular for position control. They move in small, exact steps. Each step turns the motor a set amount, like 1.8°. This lets you move things a tiny bit each time. Microstepping can make the moves even smaller. This gives smoother and better control. Stepper motors hold their spot when stopped. You do not need extra brakes. They stay in place, even if power is off for a short time.

Operation

Stepper motors turn electrical pulses into movement. Each pulse makes the motor move one step. The number of pulses tells how far it turns. The speed of the pulses sets how fast it moves. The motor’s moves match the pulses you send. This gives very accurate position control. Closed-loop control uses sensors to check the motor’s spot. This helps fix mistakes and keeps the motor on track. You can get high accuracy, with step angles as small as 0.36°. Moves can be as tiny as 2 micrometers. Stepper motors also keep strong holding torque when stopped. This is important for many machines.

Pros and Cons

Why use stepper motors for your project?

They give simple and reliable position control.

Stepper motors have high accuracy and repeatability.

You do not need feedback sensors for basic jobs, so you save money.

Closed-loop control gives even more precision and torque.

But there are some downsides:

Open-loop stepper motors use power even when still, so they get hot.

They can lose steps if they are overloaded or run too fast.

Closed-loop stepper motors cost more and need extra parts, like encoders.

Aspect | Stepper Motor (Open Loop) | Stepper Servo Motor (Closed Loop) |

|---|---|---|

Position Control | High | Very High |

Torque Stability | Medium | High |

Energy Efficiency | Low | Medium-High |

Heat Generation | High | Low |

Complexity | Low | Medium |

Tip: Use closed-loop control for the best accuracy and torque.

Uses

Stepper motors are used where position control is important.

3D printers use them to move the print head exactly.

CNC machines use stepper motors for cutting and drilling shapes.

Robotics uses stepper motors for arms and grippers that need careful moves.

Packaging machines use stepper motors to control belts and sealers.

Camera systems use stepper motors for focus and zoom.

Lab equipment uses stepper motors to move samples and tools.

Microstepping and the right driver settings help you get the best results. You can make moves more accurate and quieter by matching the motor and driver. Stepper motors give you the control you need for projects that need exact moves and reliable position control.

Gear Motors

Gear motors let a small motor make more torque. When you add a gearhead, the motor turns slower but gets stronger. This helps when you need to lift or move heavy things. You do not need a big motor for these jobs. There are different types of gear motors. You can pick dc, brushless, or stepper motors. Each type has its own good points.

DC Gear Motors

DC gear motors are easy to use and give strong torque at low speeds. Gears help the motor push or pull heavy things. These motors are good for moving belts or opening doors. Before you pick one, check some important things:

Parameter | Description / Considerations | Impact / Trade-offs |

|---|---|---|

Voltage & Current | Make sure the voltage matches your power supply. Check how much current it uses when starting or stuck. | Motors with higher voltage work better but need the right power. |

RPM (Output Speed) | This is how fast the shaft turns after gears slow it down. | Faster speed means less torque and more noise. |

Torque | Look at how much force the motor can give. | You need enough torque for your job. More torque can mean a bigger, slower motor. |

Gear Ratio | This tells how much the gears slow down the motor. | A higher ratio gives more torque but less speed and efficiency. |

Gearbox Type | There are different gears like planetary, spur, worm, and helical. | The type changes how loud, big, or strong the motor is. |

Efficiency | This shows how much power turns into movement. | Better efficiency means less heat and longer life, but can cost more. |

Duty Cycle | This tells if the motor can run all the time or just sometimes. | Motors that run all the time are bigger and cost more. |

Physical Dimensions | Check the size and shape of the motor and shaft. | Bigger motors are stronger but need more space. |

Environmental Ratings | Look at IP ratings and how well it handles heat, shock, or shaking. | Better ratings make motors last longer but can cost more and be bigger. |

Noise Level | Think about how loud the motor is. | Quieter motors can be more costly and harder to make. |

New materials and better cooling help dc gear motors last longer. They also help them run more quietly.

Brushless Gear Motors

Brushless motors are more efficient and need less care. You do not have to worry about brushes wearing out. These motors last a long time and can be up to 90% efficient. They give more torque for their size and stay cooler. Brushless gear motors are quiet, which is good when you need less noise. You can use them in HVAC, robots, and wind turbines. They work well for hard jobs and last a long time.

Brushless motors give more torque for their weight.

They last longer and need less fixing.

You can control their speed well and they are quiet.

These motors are good for tough or quiet places.

Stepper Gear Motors

Stepper gear motors help you move things exactly and with more force. Use them when you need both accuracy and strength, like in 3D printers or CNC machines. The gearhead helps the stepper motor hold its spot and move heavy things. You can check speed-torque curves to see how much force you get at different speeds. Stepper gear motors give holding torque and steady power at many speeds. This makes them good for machines that need control and strength.

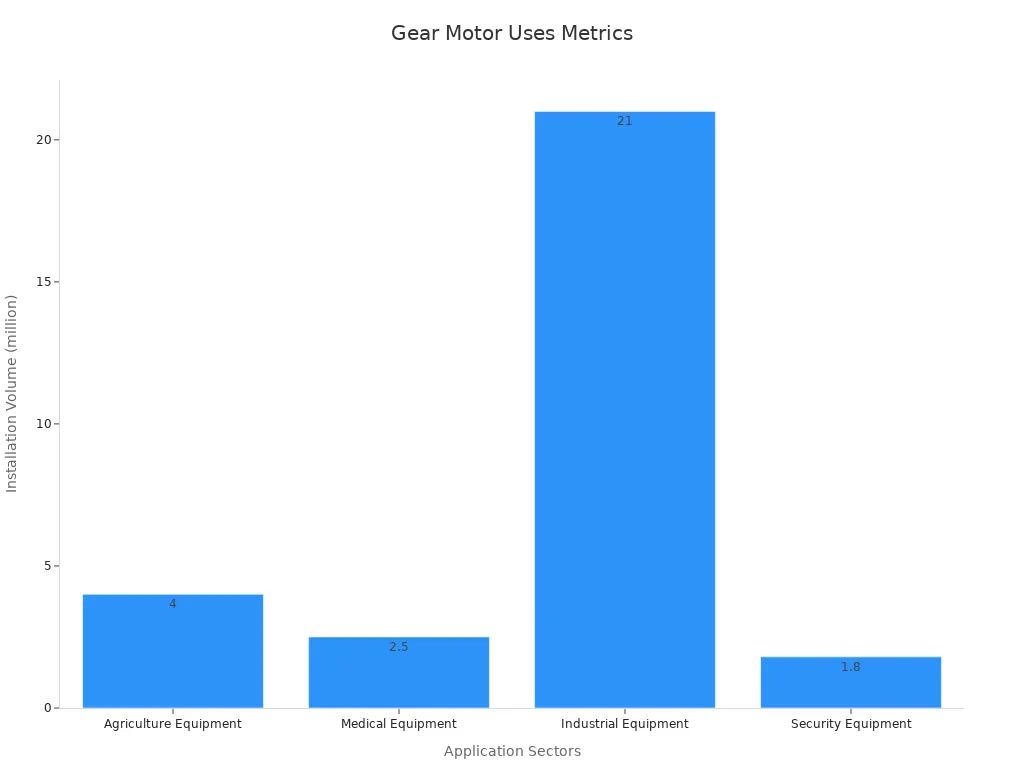

Applications

Gear motors are used in many jobs because they solve hard movement problems. They power belts, lifts, mixers, and even medical robots. Gear motors save space and energy while giving strong torque. Here are some common uses for gear motors:

Gear Motor Type | Market Share (2023) | Typical Torque Range (Nm) | Key Applications and Features |

|---|---|---|---|

Parallel Shaft Gear Motors | 42% | Up to 1,500 | Used in conveyor systems, textile, and packaging. They are efficient and small. |

Right-Angle Shaft Gear Motors | 29% | 50 to 800 | Used in escalators, mixers, and small lifts. They save space in HVAC systems. |

Planetary Gear Motors | 22% | Up to 3,000 | Used in robots, CNC machines, and medical devices. They give high torque and are very exact. |

Tip: Pick a gear motor that matches your torque, speed, and efficiency needs. This helps your machines work better and last longer.

Motor Comparison Guide

Side-by-Side

When you need to pick the right motor, you should look at what matters most for your project. Some motors give you more power. Others help you move things with high accuracy. You might want a motor that saves energy or one that costs less. Here is a side-by-side look at the four main types:

Feature | DC Motor | Brushless DC Motor | Stepper Motor | Gear Motor |

|---|---|---|---|---|

Precision | Medium | High | Very High (with position control) | Medium-High (with servo or stepper) |

Power (Torque) | High starting torque | High torque, efficient | Good holding torque | Very high torque at low speed |

Efficiency | Medium | Very High | Low-Medium | Medium |

Cost | Low | Medium-High | Medium | Medium-High |

Maintenance | Needs more | Very low | Low | Medium (depends on gears) |

Speed Range | Wide | Very wide | Limited | Low-Medium |

Noise | Medium-High | Very Low | Medium-High | Medium |

Best For | Simple, low-cost tasks | High speed, long life | Exact moves, position control | Heavy loads, slow speed |

You should choose a DC motor if you want simple speed control and low cost. Brushless DC motors work best when you need quiet operation and high efficiency. Stepper motors shine when you need position control and repeatable moves. Gear motors help you move heavy things with strong torque, even at slow speeds.

Note: If you need both high torque and exact position control, you can use servo motors. These motors combine a motor, a feedback device, and a controller. Servo motors give you the best of both worlds.

Selection Tips

You might wonder why you should pick one motor over another. The answer depends on your project’s needs. Here are some tips to help you decide:

Think about the drive mechanism. Direct rotation, ball screw, belt and pulley, or rack and pinion all need different motors.

Check the size and weight of your load. Heavy loads need motors with more torque.

Look at friction in your system. High friction means you need more power.

Decide how fast you want things to move. High speed needs a motor that can keep up.

Measure how far and how quickly you need to move. This affects your choice of motor and control method.

Ask if you need high resolution or stopping accuracy. Stepper motors and servo motors give you better position control.

Make sure your motor can hold its position when stopped. Some motors, like stepper motors, do this well.

Check your power supply and voltage. Not all motors work with every power source.

Think about where you will use the motor. Dust, water, or heat can affect your choice.

Look for special features. Open-loop or closed-loop control, programmability, feedback, and IP ratings all matter.

You should also look at technical performance metrics:

Moment of inertia tells you how hard it is to change speed.

Torque is the force that turns your load. You need to know both load torque and acceleration torque.

Speed requirements tell you how fast your motor must go.

Tip: If you need fast and accurate moves, servo motors are a strong choice. They use feedback to adjust and keep the right position. You get high torque and smooth control.

When to Choose Each Motor Type

Use a DC motor for simple, low-cost projects where you need basic speed control.

Pick a brushless DC motor when you want high efficiency, quiet operation, and long life.

Choose a stepper motor for projects that need precise position control, like 3D printers or CNC machines.

Select a gear motor when you need high torque at low speeds, such as in lifts or conveyor belts.

Go with servo motors if you need the best position control, high torque, and fast response. Servo motors work well in robotics, automation, and any job where you must control both speed and position with accuracy.

Remember: Matching the right motor to your needs helps your project run better, last longer, and use less energy.

Choosing the right motor matters because each type gives you different benefits. Brushless motors last longer, run quieter, and need less care than brushed motors, but cost more. Stepper motors give you exact moves, while gear motors help you lift heavy things. Use the table below to see why one motor might fit your project better:

Feature | Brushed DC | Brushless DC | Stepper | Gear Motor |

|---|---|---|---|---|

Lifespan | Short | Long | Medium | Long |

Noise | High | Low | Medium | Medium |

Precision | Medium | High | Very High | Medium |

Pick a motor that matches your speed, power, and control needs. This helps your project work better and last longer.

FAQ

Why should you pick a brushless DC motor over a brushed DC motor?

You should pick a brushless DC motor if you want less noise and longer life. Brushless motors need less maintenance. They also give you better efficiency and smoother speed control.

Why do stepper motors work well for precise movement?

Stepper motors move in small steps. Each step lets you control position very closely. You can use them when you need exact moves, like in 3D printers or robots.

Why do gear motors help with heavy loads?

Gear motors use gears to increase torque. This means you can lift or move heavier things without needing a bigger motor. You get more power at lower speeds.

Why does motor noise matter in your project?

Motor noise can affect comfort and safety. If you want a quiet space, like in a fan or medical device, you should choose a motor with low noise. Brushless motors are often the quietest.

Why should you care about motor efficiency?

High efficiency means your motor uses less energy. This saves you money and keeps the motor cooler. Efficient motors also last longer and work better in most projects.

See Also

Choosing And Using Batteries For Electric Motor Efficiency

Exploring ERM Vibration Motor Diagrams And Their Components

Best Uses Of 3V DC Motors In Today’s Electronics

Selecting Battery Powered Motors For Maximum Performance Benefits

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry