DC vs AC Motors: Understanding Speed Control and Torque Characteristics

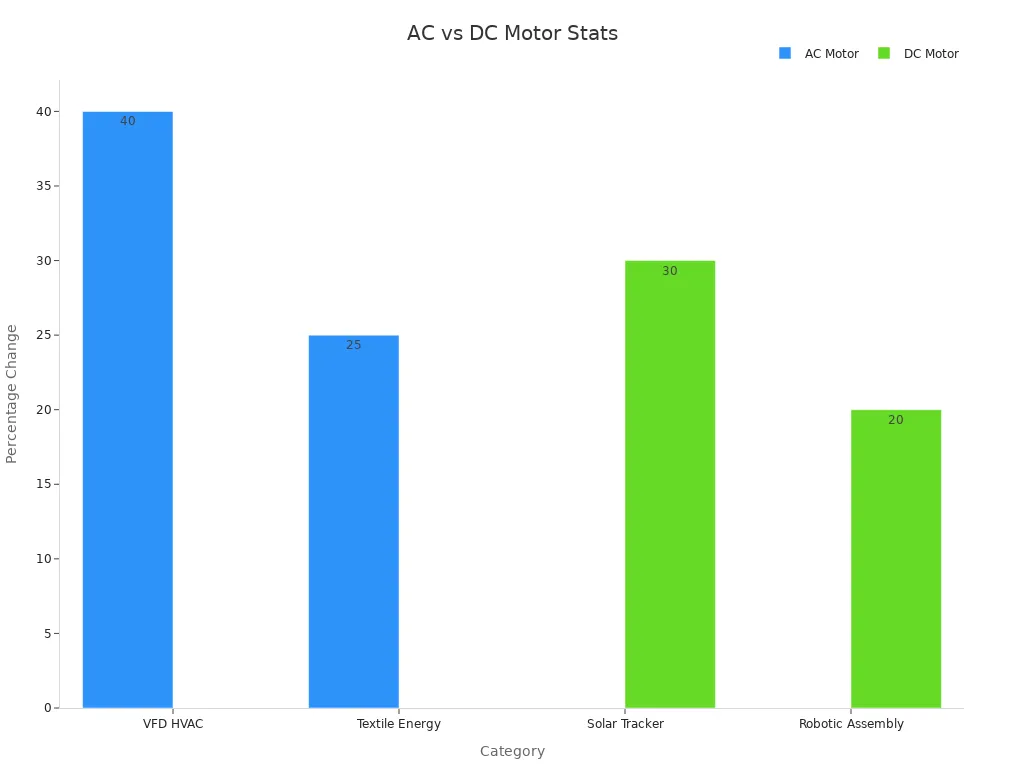

Why do engineers prefer DC motors for precise speed control and strong torque? When comparing DC vs AC motors, they handle these aspects differently. DC motors have a direct relationship between voltage and speed, making them ideal for applications like conveyor belts or elevators. On the other hand, AC motors require specialized control equipment to achieve similar performance. The chart below illustrates that DC motors respond faster and provide strong torque across all speeds, while AC motors excel at delivering consistent and robust electric power when the load remains relatively constant. Understanding the differences between DC vs AC motors helps users select the most suitable motor for their specific needs.

Key Takeaways

DC motors are easy to control. You can change their speed fast by changing the voltage. This makes them good for jobs that need quick speed changes. They also give strong torque at low speeds.

AC motors give steady torque. They work best for machines that run at the same speed. Fans and pumps use them a lot. They save energy and need less fixing.

Brushless DC motors last longer than brushed ones. They also use less energy. But they cost more at first. Brushed motors need new brushes often.

Picking the right motor depends on what the job needs. You must think about speed, torque, energy use, size, and fixing. Engineers look at these things to choose the best motor.

Use DC motors when you need exact control and strong starts. Use AC motors for jobs that run a long time. These jobs also save energy and need little fixing.

DC vs AC Motors: Key Differences

Speed Control

Electric motors are important in many machines. When people compare dc vs ac motors, they want to know which one controls speed better. DC motors are special because you can change their speed by changing the voltage. This makes dc motors great for jobs that need exact speed changes, like robots or conveyor belts.

AC motors work in another way. To change their speed, you have to change the frequency of the power. This needs special tools, like variable frequency drives. Some technical papers say that advanced controls, like observer-based control and voltage source converters, help ac motors control speed well. But these controls make things more complicated and cost more money.

Note: Some studies talk about brushless dc motors using fuzzy logic controllers and artificial neural networks. These smart controllers help dc motors keep the right speed and save energy, especially in electric cars. They can change motor settings quickly, so dc motors work well when loads change.

One big reason dc motors are good at speed control is their simple design. You can change their speed fast without extra tools. AC motors can do this too, but only if they have modern control systems. This is why dc motors are still used a lot where speed changes often.

Torque Characteristics

Torque is the force a motor uses to turn something. When people talk about dc vs ac motors, torque is a big reason to pick one. DC motors give strong torque even at low speeds. This makes them good for things like electric trains or cranes that need a lot of force to start.

AC motors act differently. They give steady torque when running at the same speed. This is good for fans, pumps, and compressors. Studies show that both dc and ac motors lose torque as they go faster. Brushless dc motors can spin faster than ac motors, but they have less torque at high speeds.

DC servo motors and ac direct-drive motors both show a link between torque and how much they weigh. AC motors do not get as much more torque as they get heavier, compared to dc motors.

AC direct-drive motors can make more torque than ac servo motors if they weigh the same. This helps them do tough jobs.

Engineers use dc motors when they need strong torque at low speeds and easy speed control. They use ac motors when they want steady work and good efficiency when the load does not change.

Electric Motors: How They Work

DC Motors

DC motors use direct current to create motion. Engineers choose these motors when they need simple and precise control. The design includes brushes that send electricity to the spinning part, called the armature. This setup lets the motor change speed quickly by adjusting the voltage. When the voltage increases, the motor spins faster. If the voltage drops, the speed slows down. This direct link between voltage and speed makes DC motors easy to control.

Why do DC motors handle changing loads so well? The answer lies in their feedback systems. These systems watch the motor’s speed and adjust the current and voltage to keep the speed steady, even if the load changes. For example, if a conveyor belt gets heavier, the motor senses the extra weight and sends more current to keep the belt moving at the same speed. Theories and experiments show that DC motors can match their speed and torque to the job by finding the right balance between current, voltage, and load. This ability helps DC motors stay stable and strong, even when conditions change.

AC Motors

AC motors use alternating current to produce motion. These motors are common in homes and factories because they work well with the electric power grid. AC motors change their speed by adjusting the frequency of the electricity they receive. To do this, engineers use devices called frequency drives. These drives let the motor run faster or slower by changing how often the electric current switches direction.

Why do AC motors work best for steady jobs? Their design gives them strong and steady torque when running at a constant speed. This makes them perfect for fans, pumps, and other machines that do not need to change speed often. AC motors start with a burst of force, known as starting torque, which helps them begin moving heavy loads. However, changing their speed or torque takes more equipment and planning compared to DC motors. This is why AC motors are chosen for jobs where the load stays the same and efficiency matters most.

Motors: Pros and Cons

DC Motors

DC motors are good at controlling speed and have strong torque at low speeds. Engineers pick these motors when they need to change speed or direction quickly. You can control DC motors by changing the voltage, which is simple for many electric systems.

Brushless DC motors use less energy than brushed ones. They do not have brushes, so they waste less power.

Brushed motors make sparks and can cause interference. Their brushes wear out, so you need to fix them more often.

Brushless motors use magnets and electronic switches. This makes them lighter and helps them work better.

Many new machines, like robots and electric cars, use brushless DC motors because they last longer and save energy.

Aspect | Benchmark / Statistic | Advantage / Disadvantage Description |

|---|---|---|

Brush Replacement | Every 2,500 hours or when brushes reach 1/3 length | You must check and change brushes sometimes. It is easier on small motors. It is harder on big motors. New brushes last longer. |

Power Range | Up to 4,000 hp for DC motors | DC motors can handle a lot of power. They do not need high voltage. |

Size and Power Density | Higher power density, smaller size | Small motors are lighter and react faster. |

Torque at Low Speed | Full torque from zero to base speed | These motors are great for jobs that need strong force all the time. |

Control Complexity | Simple voltage adjustment | It is easy and cheap to control DC motors. AC motors need more parts. |

Note: DC motors need care, especially brushed types. Brushless motors need less care but cost more at first.

AC Motors

AC motors are used a lot because they save energy and do not need much care. They work well with the power grid and give steady power for many jobs.

AC motors do not have brushes, so there are fewer parts to break. This means you do not have to fix them as much.

If you use special drives, AC motors save even more energy. They keep working well at different speeds and use less power.

AC motors give steady force when running at the same speed. This is good for fans, pumps, and compressors.

AC motors usually cost less than DC motors, especially if you buy a standard size.

Many reports say AC motors use less energy over time than DC motors. Because they do not have brushes, they last longer and break less. DC motors are better if you need fast control and strong force at low speeds. But AC motors are cheaper and save more energy for most jobs.

Tip: Use AC motors for jobs that run the same way all the time and do not need much care. Pick DC motors if you need to change speed fast or need strong force to start.

Choosing the Right Motor

Application Scenarios

Engineers pick motors based on what each job needs. DC motors are used in robots, electric cars, and conveyor belts. These jobs need fast speed changes and strong torque at low speeds. DC motors help machines start smoothly and handle heavy loads. AC motors are best for fans, pumps, and compressors. These machines run at the same speed most of the time. Factories use AC motors for big machines that work all day. Electric tools like drills and saws can use both types. But DC motors give better control when you need to be exact.

Some jobs, like exoskeletons or medical devices, need motors that match how people move. Engineers use math to figure out how much torque each joint needs. They look at torque, weight, and speed for different motors. This helps them pick the right one. Brushless motors are often chosen because they are lighter and last longer.

Tip: If you want a motor that saves energy and lasts a long time, brushless motors are a good choice.

Decision Factors

Picking between AC and DC motors depends on a few things. Engineers think about speed control, torque, weight, and how much energy the motor uses. They use computer tools to see which motor fits the job best. Sometimes, a gearbox is added to make more torque if needed. Engineers set a minimum torque for each part, like 150 Nm for a robotic leg joint.

A plan helps engineers balance numbers with real needs. They check if the motor gives enough speed and torque. They also look at how heavy it is, how long it will last, and how easy it is to fix. Brushless motors are picked a lot because they are efficient and light. AC motors are chosen for big jobs that need steady work.

Key things to think about:

How much torque and speed the job needs

The motor’s weight and size

How much energy it saves

How often it needs fixing and how long it lasts

Price and if you can get it easily

Note: The best motor depends on if you need exact control or steady power. Engineers use both facts and their own experience to choose the right one.

DC motors give better speed control and strong torque at low speeds. AC motors work best for steady jobs and save more energy over time. Readers should choose DC motors for tasks that need quick changes and strong starts. AC motors fit jobs that run at the same speed and need less care. Always check the job needs, energy use, and cost before picking motors.

FAQ

Why do engineers choose DC motors for precise speed control?

Engineers like DC motors because they can change speed easily. They do this by changing the voltage. This lets them control speed fast and accurately. DC motors react quickly when things change. This is helpful for jobs that need exact speed, like robots or conveyor belts.

Why do AC motors work better for constant loads?

AC motors give steady torque when they run at one speed. This makes them good for fans, pumps, and compressors. They use less energy over time and need less fixing. This helps save money in the long run.

Why do brushless motors last longer than brushed motors?

Brushless motors do not have brushes that wear out. This means there is less friction and less heat. Because of this, brushless motors stay cooler and last longer. They also do not need as much care as brushed motors.

Why is torque important when choosing a motor?

Torque is the force that turns a machine. High torque helps start heavy things and keeps them moving. Engineers check torque to make sure the motor can do the job. This is very important for lifts, cranes, or electric vehicles.

Why do some applications need variable frequency drives with AC motors?

Variable frequency drives help AC motors change speed by changing the power frequency. This lets machines match their speed to what is needed. Without these drives, AC motors would only run at one speed. This would make them less useful for jobs that need different speeds.

See Also

Differences Between Vibration And Frequency For Motor Specs

Main Contrasts Between Vibro Motors And Standard Types

Exploring Rotating Motor Types And How To Choose Them

A Guide To Reading And Interpreting Motor Diagrams

Selecting The Best Battery Electric Motor Setup For Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry