DC Motors with Encoders: Precision Control and Position Feedback for Advanced Applications

You can achieve precision control and very accurate movement by using a DC motor with an encoder. This setup allows you to monitor position and speed instantly. Many advanced machines, such as robot arms and telescopes, rely on this technology. For instance, the ECI 1118 rotary encoder can detect 262,144 positions in one turn, enabling tasks that require extremely high accuracy.

Device/Encoder | Accuracy/Resolution | Application Benefit |

|---|---|---|

Strausak AG Gripper Arm | 50 micrometers at tool tip | Places tools with precision control |

Discovery Channel Telescope (DCT) | 0.19 arc seconds (azimuth) | Surpasses previous position goals |

Effective feedback and precision control help your system maintain exceptional accuracy, even during challenging operations.

Key Takeaways

DC motors with encoders help control movement very accurately. They give live updates about position, speed, and direction.

Picking the right encoder is important. Optical encoders work best in clean places. Magnetic encoders are good for dirty or rough areas. Absolute encoders remember the exact spot, even if power goes out.

Closed-loop systems use encoder data to change motor actions right away. This makes machines like robots and medical tools safer and more exact.

Good wiring, the right controllers, and careful setup are needed. These steps help the motor run smoothly and send clear signals.

Encoders and DC motors are used in advanced machines like robots, CNCs, and medical tools. They help these machines move steadily, repeat actions, and save energy.

DC Motors and Encoder Integration for Precision Control

DC Motor Fundamentals

A DC motor changes electricity into movement. It has coils and wires inside. When you turn it on, it spins. To keep it working well, clean the coils. Check for loose wires or bad spots. If there are problems, the motor may stop or spark. You can look for trouble with your eyes or a heat camera. Some DC motors use smart systems to help them work better. These systems use feedback to keep the motor steady. Pulse width modulation helps control speed and direction. This lets you move things exactly where you want.

Encoder Basics and Types

Encoders help you know how far and fast things move. You can pick a rotary encoder for spinning or a linear encoder for straight lines. There are three main types: optical, magnetic, and capacitive. Optical encoders are very accurate but need to stay clean. Magnetic encoders work in dirty or wet places. Capacitive encoders do not mind dust or water but can have trouble with electric noise.

Encoder Type | Key Performance Characteristics |

|---|---|

Optical | Very clear, does not like dirt, costs more |

Magnetic | Tough, works in rough places, can get mixed up by magnets |

Capacitive | Strong, blocks dust and water, may be slower |

Encoders can be incremental or absolute. Incremental ones count steps. Absolute ones always know their place. Pick the right encoder for your job.

How Integration Enables Position Control

When you add an encoder to a DC motor, you make a feedback loop. The encoder tells the controller where and how fast the motor moves. The controller can change the motor right away. Rotary encoders send signals for every spin. Linear encoders do this for straight moves. This feedback helps fix mistakes and keeps things on track. Using special signals can stop noise and make things work better. Absolute encoders always know the spot, so you do not need to reset. By using a DC motor and encoder together, you get very good control and can move things exactly as needed.

How Encoders Deliver Precision Control and Position Feedback

Real-Time Monitoring of Position, Speed, and Direction

Encoders help you watch your system in real time. You can see the position, speed, and direction right away. When you connect an encoder to a DC motor, you get instant updates. You know how far the motor moves and how fast it spins. You also know which way it turns. This is very important for machines and robots.

Tip: Real-time feedback from encoders helps you spot mistakes fast.

Encoders are used in many factories. They help with moving things, filling bottles, and measuring lines. In robots, encoders help with welding and putting things together. The world market for encoders was $3.01 billion in 2024. It may grow to $5.93 billion by 2033. This shows that real-time feedback is very important today.

Metric/Aspect | Data/Description |

|---|---|

Global Encoder Market Size 2024 | USD 3.01 billion |

Projected Market Size 2033 | USD 5.93 billion |

CAGR (2025-2033) | 7.83% |

Industrial Sector CAGR | 7.21%, largest end-user segment |

Industrial Applications | Conveying, filling, backstop gauging, web tensioning, linear measurement, registration mark timing |

Common Use | Motion control feedback in electric motors, robotics (welding, material handling, assembly, grinding) |

Encoder Types | Rotary (largest share), Linear (second largest), Optical (largest share), Magnetic (second largest) |

Automotive Use | Steering wheel position monitoring, speed control, angular position measurement |

Vehicle Production 2021 | 80.14 million motor vehicles worldwide, with China producing over 26 million |

Importance | Real-time feedback on position, speed, and direction essential for automation and motion control |

Rotary encoders can spin up to 30,000 times each minute. They still give correct speed and position data. Many encoders use special signals to track direction, speed, and position. Magnetic encoders work well in dirty or rough places. They can handle dust, shaking, and heat. You find these encoders in wind turbines and big machines. Real-time feedback is very important in these jobs.

Closed-Loop Feedback for Enhanced Accuracy

Closed-loop feedback makes your system more accurate. The encoder sends updates to the controller all the time. The controller checks this and changes the motor quickly. This helps you reach the right speed and position.

Closed-loop systems work well in many tests. For example, medical machines like insulin pumps use closed-loop feedback. They keep things safe for longer than people can. These systems lower mistakes and make things safer. In factories, you can test and check your system often. This keeps your closed-loop system working well.

Note: Closed-loop feedback makes your projects safer and more accurate.

Robots and factories use closed-loop feedback too. With encoder feedback, a robot arm moves to the exact spot you want. Even if something pushes it, it stays on track. This is only possible with real-time feedback and high resolution.

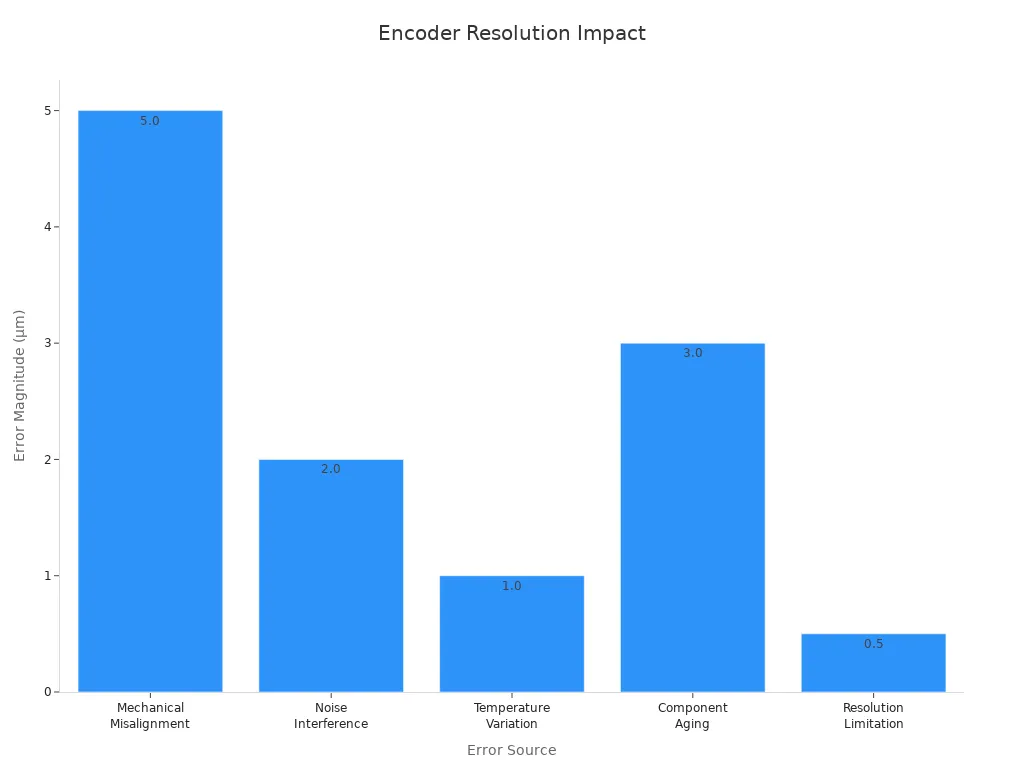

Impact of Encoder Resolution on Position Control

Encoder resolution tells how small a move you can see. High resolution means you can spot tiny movements. This gives you better control and smoother moves.

Error Source | Typical Magnitude (μm) | Compensation Method |

|---|---|---|

Mechanical Misalignment | 5.0 | Precision Mounting |

Noise Interference | 2.0 | Digital Filtering |

Temperature Variation | 1.0 | Thermal Compensation |

Component Aging | 3.0 | Regular Calibration |

Resolution Limitation | 0.5 | Interpolation |

The table shows that low resolution causes only 0.5 micrometers of error. This is less than other problems. High resolution encoders help you make fewer mistakes.

You can make your encoder see smaller moves in different ways:

Simple Division: Makes resolution four times better with little work.

Sine Fitting: Makes resolution 10 to 50 times better for medium needs.

Phase-Locked Loop (PLL): Makes resolution 100 to 1000 times better for high needs but needs more power.

Most optical encoders can count over 25 steps each turn. Some can count up to 1 million steps per turn. The smallest part on an encoder disc is about 10 micrometers. High resolution lets you control position very well and repeat moves in advanced machines.

Tip: Pick the right encoder resolution for your job. Too low loses accuracy. Too high can cost more or be harder to use.

When you pick the best encoder and use feedback, you get the best control for your project.

Position Feedback Mechanisms and Encoder Selection

How Position Feedback Works in Practice

Rotary and linear encoders help you know motor position. These tools show where your motor is and how it moves. You can use different sensors to get this information.

Hall-effect, optical, and magnetic sensors check the rotor’s spot in brushless motors.

Linear encoders watch straight-line moves.

Some systems do not use sensors. They use math to guess position and speed from voltage and current.

PWM or hysteresis control keeps the motor running smooth using feedback.

You find these feedback tools in robots, planes, and cars. They help machines work better and more accurately. These methods still work well even if there is noise or the environment changes.

Incremental vs. Absolute Encoders for Position Control

You must pick between incremental and absolute encoders. Both help track position but work differently. The table below shows their differences:

Feature | Absolute Encoder | Incremental Encoder |

|---|---|---|

Position Information | Always gives exact position | Shows changes, needs a starting point |

Reference Point | No need to set a start | Needs a start point |

Power Loss Handling | Remembers position if power goes out | Forgets position if power goes out |

Resolution | Set by design, shown in bits | Can be made better with extra steps |

Complexity | More parts, costs more | Fewer parts, costs less |

Typical Applications | Used in robots and important machines | Used in simple motion and motor control |

Both rotary and linear encoders can be absolute or incremental. Absolute encoders always know the position. Incremental encoders only show how much the position changes. If you need high detail and no lost data, use absolute. If you want simple and cheap, use incremental.

Choosing the Right Encoder for Your Application

Pick the best encoder for your job. Think about what you need to measure. Use rotary encoders for spinning. Use linear encoders for straight moves.

Follow these steps to choose well:

Decide if you need rotary or linear.

Check if your area is clean or dirty. Optical works best in clean places. Magnetic works in dirty or wet spots.

Think about how detailed you need to be. High detail helps control better. Pick high resolution if you need to see tiny moves.

Look at your money. Absolute costs more but gives better data. Incremental is cheaper for easy jobs.

Make sure your encoder fits your motor and controller.

Rotary and linear encoders work in many machines. Optical encoders are good for clean places and give high detail. Magnetic encoders are tough for hard places. Always match the encoder type, detail, and feedback to your project for the best results.

Using DC Motors and Encoders for Precise Control

Best Ways to Connect and Set Up

Pick an encoder that fits your work area. Optical encoders are very exact but need to stay clean. Magnetic encoders work well in dirty or rough places.

Make sure the encoder’s detail matches your job. Rotary encoders count spins. Linear encoders count straight moves.

Choose if you want to track changes or always know the spot. Incremental encoders show changes. Absolute encoders always know the place.

Use the right wires for your encoder. Learn about different signal types like single-ended, differential, HTL, and TTL. This keeps signals strong and clear.

Check if the encoder can handle dust, water, and the motor’s force.

Keep wires short and covered to stop noise and signal loss.

Tip: Good wires and the right encoder help you control things well.

Making Sure the Controller Works

Your controller must work with your motor and encoder. Many controllers can check speed and position using encoder data. Some controllers work with incremental encoders and use fast links like CAN bus or EtherCAT. This gives you quick updates and lets you change things fast.

New controllers can set themselves up for best results. Look for controllers with good noise blocks. This keeps encoder signals clear. The controller connects your commands to the motor. It must match well for smooth work.

Picking the Best Motor and Encoder

First, match the controller’s power to your motor. Then, pick an encoder with the right feedback, mount, and detail. For example, you might use an incremental encoder with up to 20,000 counts per spin. Or use an absolute encoder with up to 22 bits of detail. Make sure the encoder can handle dust and water if needed. Good controllers let you adjust for fast and exact moves. When all parts fit, you get steady and repeatable results.

Advanced Applications That Need Precise Position Control

Robotics and Industrial Automation

Encoders help robots and machines move to the right spot. They track every move, so robots do not miss their mark. Incremental encoders notice small changes in position. This lets the system fix mistakes right away. It makes robots and machines work better and faster. You see encoders in robot arms, AGVs, and conveyor belts. They help jobs repeat the same way each time.

Tip: Pick an encoder with enough detail for your job.

The table shows how DC motors with encoders help in tough jobs:

Sector/Application | Growth Rate / Key Statistic | Performance Benefit / Use Case |

|---|---|---|

Industrial Automation | 12.7% CAGR growth | Helps robot arms and AGVs move with care |

Electric Vehicles (EVs) | 10.3 million EV sales in 2023 | Encoders help motors save energy and control speed |

ADAS | 11.2% annual growth until 2030 | Makes cars safer with better lane and speed control |

CNC Machines and Precision Manufacturing

CNC machines need encoders for very accurate moves. Angle encoders measure how parts turn. They are very exact, better than ±10 arcseconds. Rotary encoders watch how fast things spin. This helps tools last longer and work better. Linear encoders check straight moves. They are important for machines that move in many directions.

Encoder Type | Application in CNC Machines | Accuracy and Role in Precision Manufacturing |

|---|---|---|

Angle Encoders | Measure how parts turn | Very high accuracy, better than ±10 arcseconds |

Rotary Encoders | Watch spindle speed | Good for speed control |

Linear Encoders | Check straight moves | Needed for exact moves in many directions |

Absolute Encoders | Give exact spot right away | No need to reset, saves time and lowers mistakes |

Incremental Encoders | Show changes in position | Need to reset, good for finding home and small moves |

Pick your encoder by how exact, fast, or easy you want it. This helps your machine work the same way every time.

Medical Devices and Lab Equipment

Encoders make medical machines safer and more exact. Centrifuges, blood testers, and lab robots use motors with encoders. These help control speed and position very well. Encoders keep things moving smoothly and in the right place. This is important for patient safety and test results.

Rotary encoders like HEIDENHAIN ECN 400 help aim radiation tools.

Linear encoders help blood testers and DNA machines move right.

Small encoders fit in tiny robots and wearable helpers.

Application Area | Motor Type | Role of Encoder | Benefits and Features |

|---|---|---|---|

Medical centrifuges, blood analyzers | Brushless DC motors with encoders | Tell speed, direction, and distance for control | Smooth, fast spinning; exact speed; needed for medical tests |

Automated lab equipment | BLDC gearmotors with encoders and gearboxes | Give steady motion with strong force | Quiet, smooth work; good for jobs like spinning blood |

Linear actuators in lab automation | BLDC linear actuators with encoders | Give strong and exact moves | Strong, small, and exact; used in testing and imaging machines |

Encoders give the trust and accuracy needed for advanced medical and lab tools.

You can make things move the same way every time with DC motors and encoders. These setups give strong power, smooth moves, and quick updates.

What It Means | |

|---|---|

Accurate Moves | Strong power and smooth action for steady jobs |

Speed Choices | You can change speed for better control |

Feedback | Clear data helps you repeat moves and fix mistakes fast |

Better Controllers | Two control loops help stop errors and keep things steady |

Saves Energy | Special drives use less power and work better |

Stays Reliable | Soft starts and cooling keep things working the same |

Where Used | Found in robots, medical tools, planes, and defense gear |

These systems are good for jobs that need steady and exact movement.

FAQ

How do you connect an encoder to a DC motor?

Attach the encoder to the motor’s shaft.

Connect the encoder wires to your controller.

Follow the wiring diagram for your parts.

Make sure all wires are tight and secure.

Check that the encoder lines up with the shaft.

Test everything before you start the motor.

What should you do if your encoder gives wrong readings?

Look at all wires for breaks or loose spots.

Clean the encoder if you see dirt or dust.

Make sure the encoder is lined up with the shaft.

Change any broken parts you find.

Try the system again to see if it works.

How can you choose the right encoder resolution?

Think about how tiny a move you need to see.

Higher resolution means you get more details.

Pick a resolution that matches your project’s needs.

Do not pick one too high for your controller.

Can you use DC motors with encoders outdoors?

Yes, you can use them outside.

Choose magnetic or capacitive encoders for wet places.

Cover all wires to keep out water and dirt.

Use weatherproof boxes for extra protection.

See Also

Benefits of Investing in Mini Brushless Motors for Accuracy

How To Choose The Best Mini DC Motors For Industry

Comprehensive Guide To SMD Vibration Motors For Engineers

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry