DC Motor vs AC Motor: Which is Better for Your Small-Scale Precision Application?

In the dc motor vs ac motor debate, dc motors are often best for small jobs. They give good speed control, are small, and are safer. Many people pick dc motors for tasks that need accuracy. Dc motors help when you need to fix electric motors in small spaces. People notice less noise and easier fixes with dc motors. You can look at a dc motor vs ac motor chart to help choose. Everyone should pick electric motors that fit their needs, since dc motors work well for most precision jobs. Dc motors are reliable, save money, and give better control than other electric motors. People trust dc motors for small projects, and dc motors keep showing they are useful.

Key Takeaways

DC motors give very good speed and position control. This makes them great for small and careful jobs. People use them in robotics and medical devices.

Brushless DC motors are quiet and last a long time. They also need less care than brushed DC motors.

AC motors give strong and steady power. They work well for big jobs that run all the time, like fans and pumps.

You should pick a motor based on what you need. Think about control, size, power, care, and price.

If you want fast and exact control in small spaces, use DC motors. If you want steady power and long life, use AC motors.

DC Motor vs AC Motor Overview

Key Differences

People talk a lot about dc motor vs ac motor. Dc motors are good for small, careful jobs. They let you change speed easily and react fast. This helps in things like robots or medical tools. Dc motors are small, so they fit in tight spots. Ac motors are stronger and last longer. They are best when you need steady speed and high power.

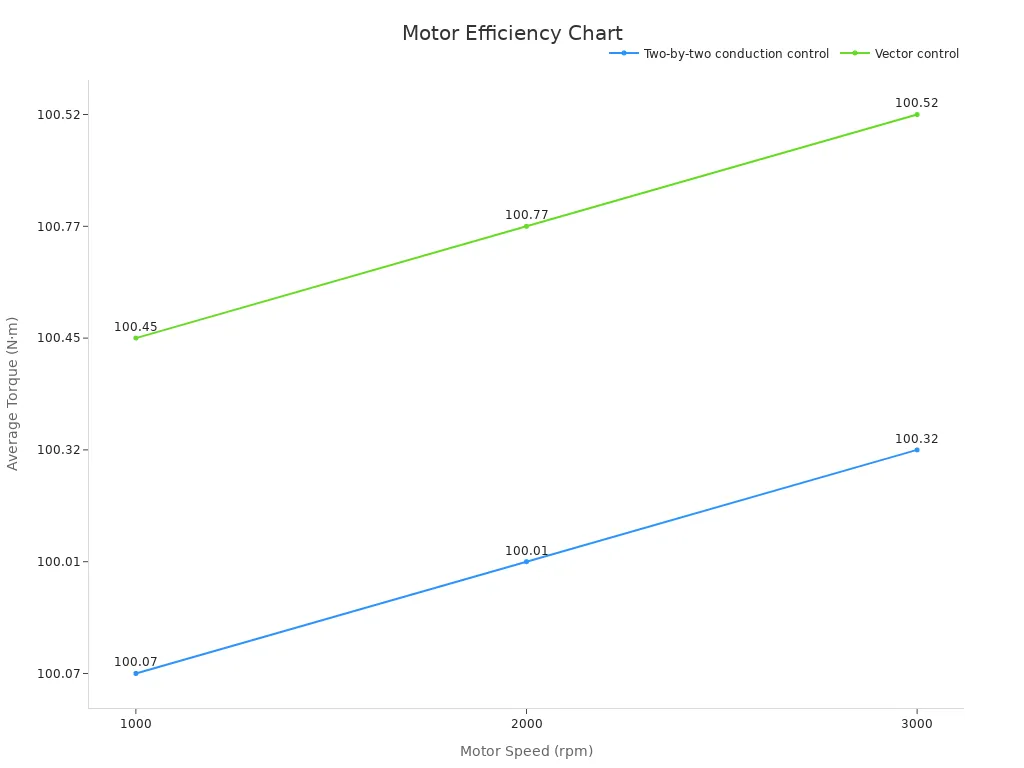

Dc motors use brushes or switches to move. This lets you change speed and position very closely. Ac motors use alternating current and need extra parts to change speed. Dc motors can have some torque ripple. But special controls like vector control help fix this. Ac motors, like induction types, run smoother. But they are not as exact as dc motors for small jobs.

Note: Brushless dc motors work well and save energy. They are good for careful jobs, but torque ripple can be a problem. Vector control helps keep torque steady and makes dc motors more exact for detailed work.

Comparison Table

Aspect | Brushless DC Motors (BLDC) | Brushed DC Motors | AC Induction Motors | Stepper Motors |

|---|---|---|---|---|

Control | Precise motion, servo control, coordinate motion | Less precise, simpler control | Operate at specific performance points | Indexing, discrete positioning |

Efficiency | Highest efficiency; typically 70-80%+ | Lower efficiency; losses due to brushes | ~30% less efficient than DC motors | Moderate efficiency |

Size | Smaller size; space-saving possible with external rotor | Larger due to brush assembly | Larger size due to construction | Compact for discrete steps |

Safety | Brushless = no sparking, longer life, less maintenance | Brushes cause sparking, more wear | No brushes, but less efficient | Safe, but depends on application |

Cost | Higher upfront cost, lower maintenance cost | Lower upfront cost, higher maintenance | Moderate cost, additional power supply | Moderate cost, application dependent |

Motor Type | Efficiency Range (%) | Control Features | Size and Space Considerations | Safety and Maintenance | Cost Considerations |

|---|---|---|---|---|---|

Electronically Commutated (EC) Motors | 60-75% (small), >80% (integral hp) | Multiple speed controls standard; PWM input control | Smaller size; external rotor option saves space | No brushes, no sparking, cooler operation | Higher initial cost; energy savings offset cost |

AC Shaded Pole Motors | 15-25% | Limited speed control; external controller needed | Larger size | No brushes; less efficient | Lower cost but higher energy consumption |

AC Permanent-Split Capacitor (PSC) Motors | 30-50% | External speed controller affects motor life | Moderate size | No brushes; moderate efficiency | Moderate cost |

~30% more efficient than AC | Precise control possible | Size varies | Brushes cause wear and sparking | Higher maintenance cost |

When you compare dc motor vs ac motor, dc motors often win for small, careful work. Dc motors are easy to control and fit in small places. Ac motors are better for strong, steady jobs. Electric motors are important in many things. You should pick the right one for control, size, and how much power you need.

Performance

Speed Control

Many engineers pick a dc motor for careful jobs. Dc motors can change speed fast and smoothly. This is great for things like robot arms or medical tools. Dc motors use electronic controls to change speed. These controls help the motor react quickly. For example, a brushless dc motor in a car fuel pump keeps fuel pressure steady by changing speed. Ac motors cannot match this level of control.

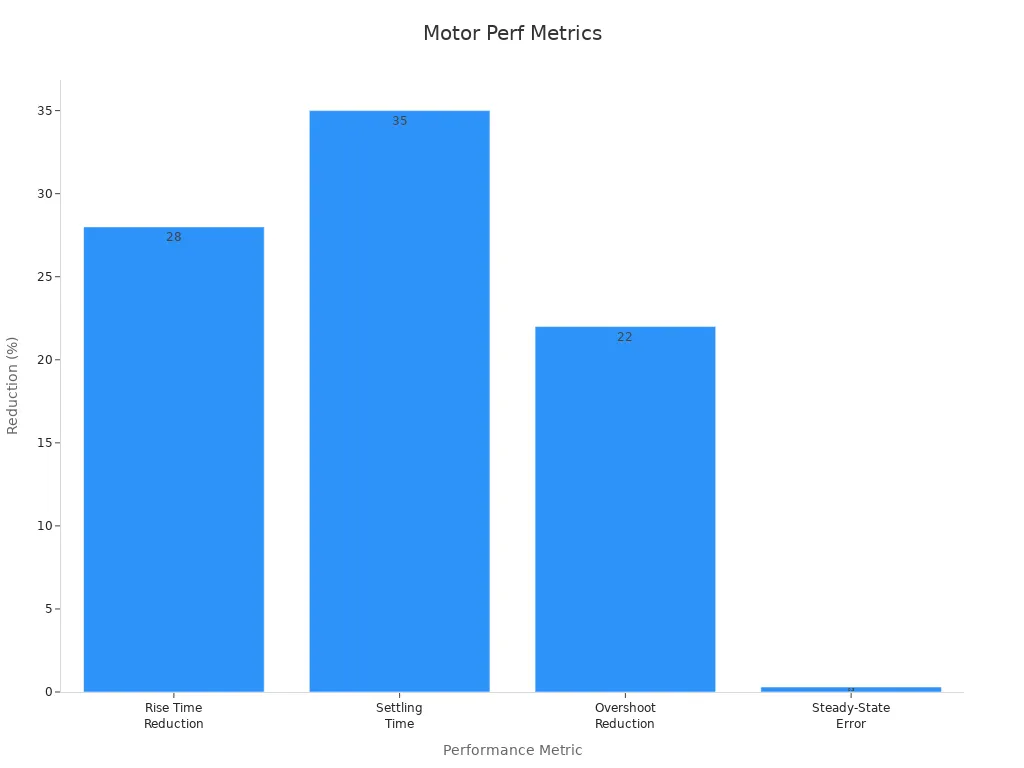

Dc motors also do well in tests. Engineers see rise time drop by about 28%. Settling time drops by about 35%. Overshoot goes down by 22% on average. Steady-state error stays very low at 0.3%. This means a dc motor can reach the right speed fast and stay there. The bandwidth of 950 Hz helps the dc motor handle quick changes. This is important for careful work.

Tip: A brushless dc motor lasts longer, up to 15,000 hours. It needs less fixing. This makes it a smart pick for jobs that need both speed control and reliability.

Torque & Precision

Torque is the force that turns a motor. Dc motors give high starting torque. This means they can move heavy things right away. This is good for machines that start and stop a lot. Dc motors can keep their torque steady at low speeds. This helps in things like camera gimbals or small belts. Smooth and accurate movement is important for these jobs.

Dc motors use microcontrollers for brushless commutation. This gives them fast response and better control. The table below shows how a dc motor helps with careful jobs:

Performance Metric | Improvement / Value | Example / Detail |

|---|---|---|

Rise Time Reduction | Average ~28% reduction | Mode 3: from 0.0379 s to 0.0025 s (~93.40% reduction) |

Settling Time Reduction | Average ~35% reduction | Mode 2: from 0.0516 s to 0.0037 s (~92.83% reduction) |

Overshoot Reduction | Average ~22% reduction | Mode 3: from 0.3116% to 0.0040% (~98.72% reduction) |

Steady-State Error | Minimized to 0.3% | Consistently low across simulations indicating high precision |

Gain Margin | Infinite | Indicates very high robustness to gain variations |

Phase Margin | ~179.58° (close to 180°) | Ensures excellent phase stability under varying conditions |

Bandwidth | 950.3757 Hz | High bandwidth enables fast transient response and handling of high-frequency components |

A dc motor reacts well to sudden changes in load. It keeps its speed steady. This is important for careful work. Dc motors are a top pick for small jobs where accuracy and quick response matter most.

AC Motor Power

Ac motors are best when you need more power. They can handle big loads and run for a long time. Ac motors are good for fans, pumps, and other machines that need strong power. They are also very efficient, especially when they are big. For example, an ac induction motor can be 90–93% efficient. A synchronous ac motor can be up to 99% efficient.

The table below shows how bigger ac motors get more efficient:

Motor Power (HP) | Typical Efficiency Range (%) | Notes |

|---|---|---|

5 | ~80–82.5 | Smaller motors have lower efficiency |

20 | ~82.7–86.5 | Efficiency improves with size |

100 | ~90.3–93.0 | Larger motors exceed 90% efficiency |

250 | ~91.0–93.9 | Efficiency continues to increase |

1,000 | ~92.3–95.5 | High efficiency at large scale |

5,000 | ~95.2–97.3 | Very high efficiency for very large motors |

Ac motors do not control speed as well as dc motors. They often need extra parts to change speed. This makes them cost more and harder to use. But if you need to move heavy things with high efficiency, an ac motor is the best choice.

Note: Ac motors are best for jobs that need steady speed and strong power. Dc motors are still the best for small, careful jobs that need fast speed changes and good control.

Efficiency & Noise

Power Consumption

AC motors are known for being very efficient. They use less energy over time. This helps save money on power bills. Many people pick AC motors to save energy. DC motors give better control of speed and torque. For some jobs, DC motors use more power when starting. DC series motors can use up to 500% of their full-load torque at startup. AC motors can also need a lot of power to start. Sometimes, they use 7-8 times more current than when running. Bigger AC motors get even more efficient.

Here is a simple table to compare power use and features:

Aspect | AC Motors | DC Motors |

|---|---|---|

Starting Current | Can use 7-8 times more current for a short time; depends on type | Series motors can use a lot of current at start; shunt motors use less |

Torque Characteristics | Medium starting torque; steady speed in synchronous types | Great torque control; high starting torque in series and compound |

Speed Regulation | Not as exact; synchronous motors need special control | Very good speed control in shunt and compound motors |

Energy Efficiency | Very efficient, especially when motors are big | Good efficiency, but sometimes less than AC motors |

Why does this matter? People who want to save energy and money often choose AC motors. If you need fast control and quick changes in small devices, DC motors are better. DC motors may use more power when starting.

Noise Levels

Noise can make a workspace less comfortable and safe. AC motors are usually quiet, especially induction types. Their design helps them run smoothly and quietly. DC motors can be louder, mostly brushed types. The brushes rub and make noise. Brushless DC motors are much quieter. This is important for things like medical tools or lab machines. Low noise helps people work better and feel comfortable.

AC motors: Run quietly, less shaking, good for quiet places.

DC motors: Brushed types are louder; brushless types are quieter.

Tip: If you need a motor that is very quiet, pick a brushless DC motor or an AC induction motor.

Maintenance Needs

How long a motor lasts and how much care it needs is important. AC motors have a simple build with fewer moving parts. This makes them last longer and need less fixing. They can work for years without much care. DC motors, especially brushed ones, need more attention. The brushes wear out and must be changed. Brushless DC motors last longer and need less fixing.

Why does this matter? People who want a motor that lasts long and needs little care pick AC motors. If you want a motor that is easy to fix, DC motors are a good choice for small jobs.

AC motors: Last a long time, need little care, work for many years.

DC motors: Brushed types need more care, but brushless types last longer.

Note: Picking the best motor means thinking about how long it lasts, how much care it needs, how much energy it uses, and how reliable it is.

Suitable Application

DC Motor Use Cases

DC motors are important for many careful jobs. Engineers pick them when they need quick and exact control. These motors help robots move arms at the right speed and spot. Medical devices use DC motors to make safe and steady moves. In mobile robots, dual-loop PID control keeps errors under 1%. It also helps the robot recover fast from bumps or load changes.

Adaptive Neuro-Fuzzy Inference System controllers in DC motors stop overshoot and settle in 0.18 seconds.

Imitation learning and fuzzy logic systems make DC motors more stable and strong for real-time speed control.

Model Reference Adaptive Control works better than old controllers. It keeps speed steady even when loads change.

Neural network-based PID controllers help brushless DC motors save energy and handle new jobs.

Engineers say tuning PID settings is important for DC motors in robots and automation. This makes them more exact and quick to respond.

Brushless DC motors are used in cleanrooms for making semiconductors. These motors do not have brushes, so they make less dust and last longer. Built-in encoders help control speed and position very well. This is needed for handling fragile wafers. Cleanroom-safe covers and high ratings like IP65 help these motors meet tough rules. Companies see better product quality, more good parts, and less downtime after using brushless DC motors.

These examples show why DC motors are best for jobs that need high accuracy, fast response, and trust. They can use smart control systems, so they are great for robots, UAVs, medical tools, and clean places.

AC Motors in Practice

AC motors are used a lot in factories. Three-phase induction motors are the most common in industry. They make up 70–80% of all motors in factories. These motors can handle heavy work and run for a long time with little care. In factories, HVAC, and mining, AC motors keep fans, pumps, and compressors working well.

Industry stories show that picking and caring for AC motors helps them work better and last longer. For example, torque de-rating stops overheating. This lowers heat stress and keeps insulation from failing. This means less costly downtime and longer machine life. In making semiconductors, AC motors help with tricky jobs where keeping things clean is key. Engineers use careful motor control to keep work going and cut down on problems.

AC motors use less energy over time, so companies save money on power. Their simple build means fewer parts can break. They last longer and need less fixing. These things make AC motors best for jobs that need steady power, good efficiency, and long life.

Choosing the Right Motor

Picking the right motor depends on what the job needs. Engineers look at some main things to match the motor to the task:

Performance: Does the job need exact speed, strong torque, or both?

Environment: Will the motor face dust, water, or hot or cold?

Control: Does it need special speed and position control?

Maintenance: How often can you fix the motor?

Cost: What are the first and later costs?

The table below helps compare which motor fits each job:

Motor Type | Best For | Key Advantages | Typical Applications |

|---|---|---|---|

Brushed DC Motor | Simple, low-cost, small-scale tasks | Easy control, low price | Toys, small tools, hobby projects |

Brushless DC Motor | Precision, clean, and quiet environments | High accuracy, low noise, long life | Robotics, medical devices, UAVs |

AC Induction Motor | Heavy-duty, continuous operation | High efficiency, low maintenance | Fans, pumps, compressors, conveyors |

Synchronous AC Motor | Constant speed, high precision | Stable speed, reliable performance | Automation, robotics, process lines |

Tip: If you need fast, exact control in a small space, DC motors are best. If you need steady power and long life, AC motors are better.

Here is a quick checklist for picking a motor:

Need exact speed or torque control? Pick a brushless DC motor.

Need to run machines all day with little care? Pick an AC induction motor.

Working in a clean or sensitive place? Pick a brushless DC motor with a clean cover.

Need a simple, cheap fix for a small job? Pick a brushed DC motor.

Need steady speed and high trust? Pick a synchronous AC motor.

Matching the motor to the job gives the best work, trust, and saves money. This way helps engineers and designers make good choices for every job.

Engineers pick dc motors for small, careful jobs. Dc motors are easy to control and fit in tight spaces. They can change speed quickly and are very accurate. Ac motors are better for big jobs that need steady speed. Dc motors are used in robots, medical tools, and cleanrooms. They do not need much space and are safer to use. Dc motors are simple to fix and take care of. They work well with smart control systems. Dc motors are the best for detailed tasks. You can use the decision guide to help choose the right motor.

FAQ

Why do engineers prefer DC motors for precision tasks?

Engineers like DC motors for careful jobs. These motors let you control speed and position well. DC motors react fast to changes. This helps machines do small or careful work. DC motors are small, so they fit in tight spots. That makes them good for small devices.

Why do AC motors last longer than DC motors?

AC motors have fewer parts that move. They do not use brushes that wear out. This means less rubbing and less heat. So, AC motors can run for many years. They do not need much fixing. That is why factories use AC motors a lot.

Why does noise matter when selecting a motor?

Noise can make work less safe and less comfy. Loud motors can bother workers or mess up sensitive tools. Brushless DC motors and AC induction motors are quiet. Many people pick these motors for hospitals, labs, or offices. Quiet motors are important in these places.

Why do DC motors need more maintenance?

Brushed DC motors have brushes that touch moving parts. These brushes wear out after some time. When brushes are gone, the motor can stop or get weak. You need to check and fix DC motors often. Brushless DC motors do not have this problem because they have no brushes.

See Also

How To Choose Mini DC Motors For Industrial Use

Benefits Of Investing In Mini Brushless Motors For Precision

Choosing The Best 3 Volt DC Motor For Projects

Picking The Ideal Battery Powered Motor Setup For Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry