DC Motor Parts Explained: A Comprehensive Breakdown of Internal and External Components

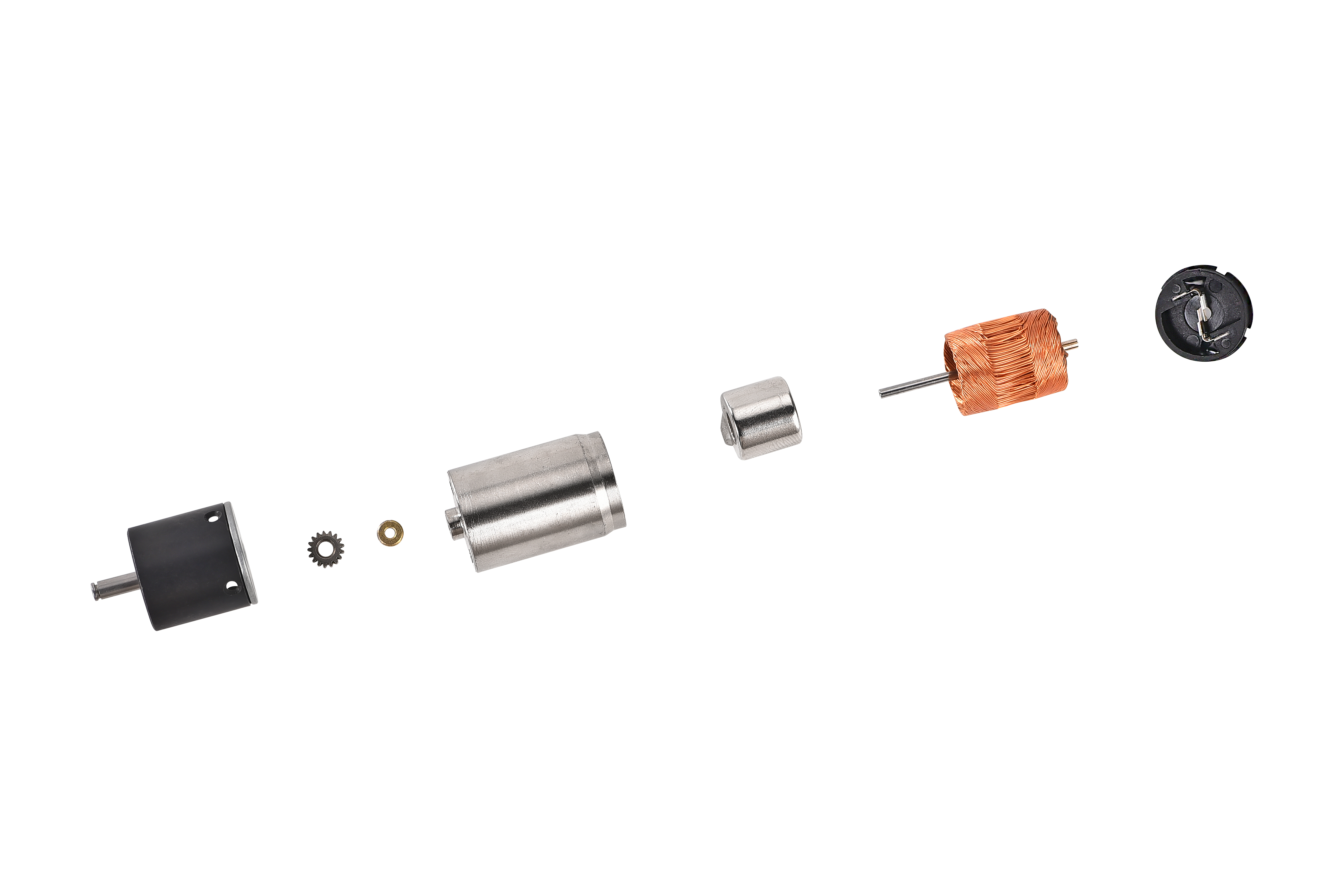

DC motors are everywhere - from factory equipment to your power tools, there are ones for everything. Their working principle is similar to an energy converter, converting electrical energy into motion. But how exactly does it work? It all depends on the synergy between the key components:

The armature and the rotor: The "power component" that rotates when current passes through it.

The commutator and the brush: Like an intelligent switch, it changes the direction of the current to keep the operation normal

The housing and the terminal: Protecting the system and connecting the power supply

Here are the reasons for their importance:

Maintenance can save costs: Not conducting inspections may lead to more than 7 times the number of failures (data shows that the failure rate increases from 0.01 per year to 0.09)

Control = Knowledge: Torque depends on the current (T = kt × Ia) - understanding this, you can control the performance

Avoid downtime: Early detection of worn-out brushes can prevent sudden failures

Whether you are an engineer or just out of curiosity, understanding these basic principles can help extend the lifespan of the machine and make it run more efficiently.

Key Takeaways

Knowing DC motor parts, like the armature and commutator, helps with repairs.

Checking brushes and bearings often stops damage and keeps the motor working well.

The cooling fan stops the motor from overheating, which can break parts and cost money to fix.

A strong housing keeps the motor safe from outside harm, making it last longer.

Understanding how all parts work together helps find problems early and keeps the motor reliable.

Internal Components of a DC Motor

Armature

The armature is like the motor's heart. It changes electrical energy into movement. Why is it so important? The armature has a core made of thin iron sheets and copper wires wrapped around it. When electricity flows through these wires, it meets the magnetic field from the motor's field winding. This meeting creates a force called torque, which makes the motor spin.

How the armature is designed affects how well the motor works. Studies show that improving things like wire thickness and motor size can make it more efficient. For example, smart methods like the JAYA algorithm help motors work better and use energy wisely. These improvements make the armature a key part of the motor's success.

Commutator

The commutator is another important part of the motor. Its job is to switch the direction of electricity in the armature wires. This switching keeps the motor spinning. Without the commutator, the motor would stop after half a turn. Why does this switching matter? It keeps the motor's force steady, so it runs smoothly.

The commutator needs to be strong to last long. Problems like sparks or loud noises can mean it's wearing out. For instance, high heat might show friction or resistance, which wears it down faster. Good designs, like using quality brushes, help avoid these problems. These features make the commutator work better and last longer.

Problem | What It Means |

|---|---|

Sparks | Worn or damaged parts, especially during speed changes. |

Loud noises | Possible mechanical issues, often with vibrations. |

High heat | Friction or resistance causing faster wear. |

Uneven motor performance | Trouble with brush and commutator contact, seen during startup. |

Brushes

Brushes are small but very important for the motor. They connect the motor's still parts to its moving parts. Why do we need brushes? They let electricity flow into the armature, helping the motor run well.

What brushes are made of and how they’re built matter a lot. Most are made from carbon or graphite, which conduct electricity well and last longer. But brushes wear out over time. Checking them regularly can stop problems like sparks or uneven motor running. Healthy brushes make the motor work better and last longer.

Tip: Check your brushes often for wear. Replacing them on time saves money and avoids delays.

Rotor

The rotor is the spinning part of a DC motor. It changes electricity into movement. Why is the rotor important? It works with the magnetic field to make torque. Torque is the force that spins the motor. If the rotor isn’t designed well, the motor won’t work efficiently.

The rotor’s design affects how the motor performs. For example:

Steel disks are stacked to build the rotor. This lowers energy loss and boosts efficiency.

Balancing the rotor reduces friction and resistance. This makes the motor last longer.

Coils are added to the rotor to strengthen the magnetic field. This improves torque and smooths motor operation.

A good rotor design makes the motor reliable and efficient. Think of the rotor as the motor’s backbone.

Bearings

Bearings are small parts that help the rotor spin smoothly. Why are bearings important? They cut down friction between moving and still parts. This keeps the motor running quietly and efficiently. Without bearings, the motor would wear out quickly.

Bearings also keep the rotor aligned. Good alignment stops vibrations and noise. This improves how the motor works and makes it last longer. Taking care of bearings, like cleaning and oiling them, is key. It prevents damage and saves money on repairs.

Windings

Windings are wires wrapped around the motor’s core. They create the magnetic field that moves the rotor. Why are windings so important? They control the motor’s power and efficiency. Better windings mean better motor performance.

Different winding setups can improve how the motor works. For example:

Two sets of windings can double the motor’s torque.

Special designs make the motor more reliable without losing power.

Windings also help manage heat. Bad windings can cause overheating, which damages the motor. By improving windings, the motor stays cool and works well.

Tip: Check your windings often for damage. Fixing small issues early keeps your motor running smoothly.

External Components of a DC Motor

Housing/Frame

The housing, or frame, keeps the motor's inside parts safe. It blocks dust, water, and damage from outside. Why does this matter? Without protection, the motor's parts could break or wear out quickly. The housing also holds everything together while the motor works.

Modern housing designs are strong but lightweight. Materials like aluminum and steel are often used. These materials don’t rust and can handle heat well, making the motor last longer. In advanced machines like robots or drones, housing designs reduce electrical interference. This helps the motor work better.

Tip: Look for cracks or damage on the housing often. A broken frame can let harmful things in and lower the motor's efficiency.

Terminals

Terminals are where electricity enters the motor. They connect the motor to its power source, letting current flow steadily. Why are terminals important? Without them, the motor wouldn’t get the energy it needs to run.

Good terminal design prevents problems. Bad connections can cause overheating or electrical issues. High-tech motors use terminals with safety features like fault detection. These features catch problems early and protect the motor from damage.

Here’s what advanced terminals can do:

Feature | Description |

|---|---|

Efficiency | Works at over 98.5% in brushless DC motors up to 300 W |

Thermal Management | Spreads heat evenly, so no heat sink is needed |

Fault Protection | Built-in safety features and external monitoring for better performance |

Note: Keep terminals clean and tight. Loose or dirty connections can make the motor work poorly.

Shaft

The shaft moves power from the motor to other parts. It spins to drive gears, wheels, or other connected devices. Why is the shaft important? It turns the motor's movement into useful energy for your machine.

A good shaft design saves energy and works smoothly. Balanced shafts reduce shaking, which helps the motor last longer. Some shafts are made for specific tasks, like handling heavy loads or fast speeds. This makes sure the motor works well in different situations.

Tip: Check the shaft for wear or misalignment often. Fixing small issues early avoids big repairs and keeps the motor running well.

Cooling Fan

The cooling fan helps keep the DC motor working well. It stops the motor from overheating by removing extra heat. Without cooling, the motor parts can wear out faster. This leads to breakdowns and expensive repairs.

Why is the cooling fan important? Heat can harm motors. When the motor runs, it makes heat from friction and resistance. Too much heat can damage parts like windings and bearings. The cooling fan keeps the motor cool, making it last longer and work better.

Most cooling fans spin automatically with the motor shaft. As it spins, it moves air to cool the motor. The fan’s size and blade shape affect how well it works. Bigger fans with better blade designs move more air. This helps high-performance motors stay cooler.

A bad cooling fan can cause big problems. Signs include strange noises, less airflow, or overheating. Regular checks and cleaning can prevent these issues. Dust-free fan blades improve airflow and cooling.

Modern cooling fans have extra features. Some use light materials like plastic to save energy. Others are quiet, which is good for noise-sensitive places. These designs protect the motor and improve how it works.

Tip: Check the cooling fan during maintenance. A clean fan keeps the motor running smoothly and avoids failures.

How Internal and External Components Work Together

How the armature and commutator work together

The armature and commutator are a team in a DC motor. The armature makes torque by meeting the magnetic field. The commutator changes the current's direction to keep the motor spinning. Without this teamwork, the motor can't keep steady speed or power.

Tools like Simscape show how these parts work together. They connect models of the armature and commutator to study their effects. Even small misalignments can lower torque and cause problems. Knowing this helps keep the motor running its best.

How the housing and shaft support the motor

The housing and shaft give the motor strength and stability. The housing keeps dust and damage away from the motor's inside parts. The shaft moves the rotor's spinning energy to gears or wheels for use.

Studies show why these parts matter. Better housing designs make building motors easier. Balanced shafts cut friction torque by 14.5%. These changes make motors work better and cost less to make.

Metric | Old Motor | Improved Motor | Improvement |

|---|---|---|---|

Cogging Torque (mNm) | 138 | 36.5 | 73.5% less |

Friction Torque (mNm) | 21.3 | 18.2 | 14.5% less |

Power Output Increase (%) | N/A | N/A | 11% more |

Production Cost Decrease (%) | N/A | N/A | 10% less |

Manufacturing Complexity | High | Low | Easier to build |

How brushes and cooling fans help the motor

Brushes and cooling fans are key for motor efficiency. Brushes send electricity to the armature, keeping torque and speed steady. Worn brushes can cause sparks and uneven running, so check them often.

Cooling fans stop the motor from overheating by removing extra heat. Too much heat can harm windings and bearings, shortening the motor's life. New fan designs move air better, keeping motors cool even during hard work. This is especially helpful for high-speed motors that make a lot of heat.

Together, brushes and fans help the motor run smoothly and last longer, even in tough conditions.

Knowing the main parts of a DC motor helps you fix and care for it better. Every part, like the armature and cooling fan, is important for smooth working. Understanding how these parts work together helps you spot problems early and make the motor last longer.

Learning about DC motor parts helps you improve how it works and avoid delays. Whether you're fixing machines at work or at home, this knowledge helps you make smart choices. Learn more to boost your skills and keep your motor working well.

FAQ

Why is regular maintenance important for a DC motor?

Taking care of your DC motor helps it work well. It stops parts like brushes and bearings from wearing out. This lowers the chance of breakdowns. Skipping maintenance can cause overheating or poor performance. Fixing problems early saves money and keeps the motor lasting longer.

Why do DC motors use brushes?

Brushes send electricity to the armature, helping the motor spin. Without brushes, the motor won’t work. They keep the current steady, making the motor run smoothly. Checking and replacing worn brushes stops problems like sparks or uneven running.

Why does a DC motor need a cooling fan?

The cooling fan stops the motor from getting too hot. Heat can harm parts like windings and bearings. This makes the motor wear out faster. A good cooling fan keeps the motor cool and working well, even during hard tasks.

Why is the commutator essential in a DC motor?

The commutator changes the current’s direction in the armature. This lets the motor keep spinning. Without it, the motor would stop halfway. A strong commutator helps the motor run smoothly and keeps torque steady.

Why should you inspect the motor housing regularly?

The housing keeps the motor’s inside parts safe. It blocks dust, water, and damage. Cracks or breaks can let harmful things in, causing failures. Checking the housing often protects the motor and helps it last longer.

See Also

Understanding Motor Brushes: Key Elements for ERM Motor Efficiency

A Guide to Interpreting and Analyzing Motor Diagrams

Exploring Motor Diagrams: Components, Varieties, and Uses in ERM Motors

All You Need to Know About Mini Motors: Types and Uses

Essential Insights on Vibration Motors: Varieties and Selection Tips

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry