DC Electric Motor speed control methods for industrial applications

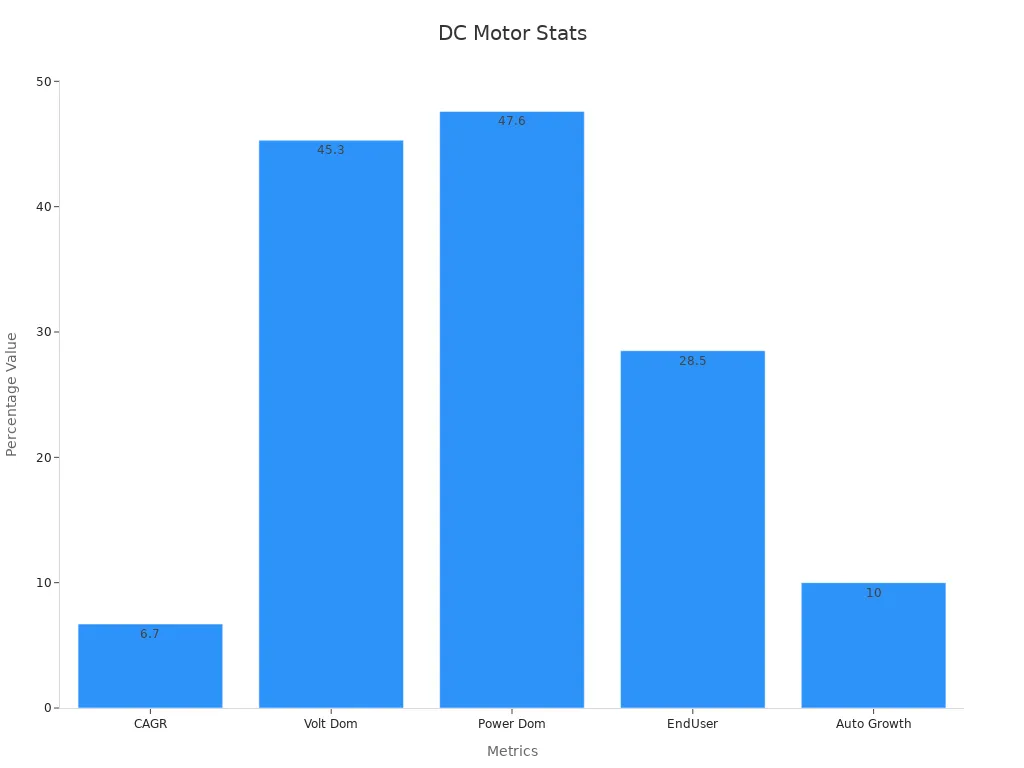

You need reliable dc electric motor speed control in every industrial setting. The most effective methods for controlling dc motor speed include armature voltage control, flux control, and advanced techniques like pulse-width modulation. Precise speed control helps you boost energy efficiency, improve safety, and optimize your process. The global dc drive market reached $5.3 billion in 2024, showing strong demand for dc motor speed control across oil & gas, manufacturing, and automotive sectors.

You can use different methods for controlling dc motor speed to match your specific needs and equipment. Choose the right dc electric motor control to keep your speed steady and your operations smooth.

Key Takeaways

Controlling DC motor speed improves energy efficiency, safety, and process quality in industrial settings.

Pulse Width Modulation (PWM) offers precise, efficient, and reliable speed control with low energy loss.

Closed-loop feedback uses sensors to keep motor speed steady, even when loads change, ensuring accuracy.

Choose a control method based on your needs for precision, cost, and maintenance to get the best results.

Combining PWM with closed-loop feedback provides the most efficient and stable motor control for automation.

DC Motor Speed Control Basics

Why Speed Control Matters

You need to understand why speed control is so important for your dc motor. When you adjust the speed, you can match the motor’s output to your process needs. This helps you save energy, reduce wear, and keep your equipment running safely. In many industries, you must keep motor speed steady even when the load changes. If you let the speed drift, you risk damaging products or causing safety issues.

DC motors work on a simple principle. When you run current through a conductor in a magnetic field, it creates a force that spins the motor. You control the speed by changing the armature current. This changes the torque and, in turn, the speed. Since Faraday’s discovery of electromagnetic induction in 1831, engineers have improved dc motors with better commutators and brushes. Today, you can use modern brushless dc motors for higher efficiency and less maintenance.

The basic equations for dc motor speed control show how voltage, current, torque, and speed connect. For example, the voltage equation is V = E + Ia × Ra. The back EMF (E) links directly to motor speed. When you control the voltage, you control the speed. This makes dc electric motor speed control both practical and precise.

Key Factors in Method Selection

When you choose a method for controlling dc motor speed, you need to look at several key factors:

Efficiency: PWM and closed-loop control give you high efficiency and less heat.

Precision: Closed-loop and PWM methods help you keep motor speed steady, even if the load changes.

Complexity: Simple on/off or analog controls are easy to set up. Closed-loop systems need more complex circuits.

Cost: Basic controls cost less. Advanced systems with feedback and microcontrollers cost more.

Maintenance: PWM and closed-loop controls can make your dc motor last longer and need less service.

Application needs: Some jobs only need simple speed control. Others need precise and dynamic control.

Tip: Use PWM control for most industrial dc motor applications. It gives you precise, efficient, and reliable motor speed control.

You can see these factors in the table below:

Factor | On/Off Control | PWM Control | Analog Control | Closed-Loop Control |

|---|---|---|---|---|

Efficiency | Low | High | Low | High |

Complexity | Simple | Moderate | Simple | High |

Cost | Low | Moderate | Low | High |

Precision | Low | High | Moderate | High |

Maintenance | Low | Moderate | Low | Moderate |

Speed Control Range | Limited | Wide | Limited | Wide |

Heat Generation | High | Low | High | Moderate |

By understanding these basics, you can select the best dc motor speed control method for your needs.

Voltage Control Methods

Armature Voltage Control

You can control the speed of your dc motor by adjusting the armature voltage. This method keeps the field current steady while you change the voltage applied to the armature. When you increase the armature voltage, the motor speed goes up. If you lower the voltage, the speed drops. This approach works well for separately excited dc motors.

A real-world example comes from an industrial test by the H2politO team at Politecnico of Turin. They used armature voltage control on a Permanent Magnet dc motor. By limiting the armature voltage based on back EMF, they kept the motor speed stable across different loads. The test showed that this method helped the motor run efficiently and kept the speed steady, even when the load changed.

You can see how armature voltage control compares to other methods in the table below:

Performance Aspect | PI Controller | ANN Controller | Armature Voltage Control Theory |

|---|---|---|---|

Response Time | Slow | Faster | Speed regulated by varying armature voltage |

Peak Overshoot | Large | Very low | Smooth and precise speed control |

Settling Time | Large | Very small | Control via armature voltage transfer function |

Steady-State Error | Zero | Zero | Smooth speed transition from zero to base speed |

Adaptability to Load Changes | Poor | Better | Theoretical equations explain control dynamics |

Industrial Suitability | Widely used | Promising | Effective for precise speed regulation in dc motors |

Supply Voltage Variation

You can also change the supply voltage to control the speed of your dc motor. This method works best for small motors or simple applications. You use a variable power supply or a transformer to adjust the voltage. When you raise the supply voltage, the motor speed increases. When you lower it, the speed decreases. This method is easy to set up, but it may not give you the best efficiency for larger motors.

If you want more precise control, adding a dc speed controller can help. This device lets you fine-tune the voltage and keep the motor speed steady, even if the load changes.

Pros and Cons

When you choose a voltage control method, you need to weigh the advantages and disadvantages. Here are some key points:

Pros:

Simple setup and operation

Smooth and precise motor speed control

Works well for many industrial dc motor applications

Cons:

Contact materials can affect performance (for example, coin silver has good contact but poor corrosion resistance)

Wiper friction and brush life can change over time

High currents may cause wear on breaker points

Control Method / Component | Pros | Cons |

|---|---|---|

Armature Voltage Control | Simple, smooth speed control, effective for many dc motors | Contact wear, maintenance needed, efficiency drops at low speeds |

Supply Voltage Variation | Easy to use, low cost for small motors | Not efficient for large motors, limited precision |

Tip: For most industrial uses, armature voltage control gives you the best mix of precision and reliability for dc electric motor speed control.

Armature Resistance Control

How It Works

You can use armature resistance control to adjust the speed of your dc motor. This method involves placing a variable resistor in series with the armature circuit. When you increase the resistance, you cause a voltage drop across the resistor. This drop reduces the voltage that reaches the armature, which lowers the speed of the dc motor.

Controlled tests, such as the brake test on dc shunt motors, show how this method works. When you add resistance, the voltage across the armature drops. The back EMF also decreases, and the motor slows down. The armature volt-drop test measures the voltage drop across the commutator segments. This test confirms that more resistance leads to a lower armature voltage and reduced speed.

You can see these effects in lab experiments and simulations:

Adding resistance in series with the field winding can reduce field current by about 25%. This change increases motor speed to around 1816 rpm, decreases counter EMF to about 111.7 V, and causes armature current to rise with overshoot up to 4.45 A.

If you increase armature resistance by 3 Ω while reducing load torque and field current, the final speed reaches about 1789 rpm, counter EMF drops to 110 V, and armature current settles at 1.46 A.

Weakening the field by inserting large resistance can make the motor speed increase sharply under no-load, risking damage from overspeed and high armature current.

⚠️ Note: Armature resistance control can cause the armature current to surge up to 13 times the rated value, especially if you weaken the field or run the dc motor with little load.

Advantages and Limitations

Armature resistance control gives you a simple way to change the speed of your dc motor. You can use this method for quick speed changes in both directions. The control accuracy is high, and the field current and torque stay constant during operation. This method works best for short tasks or fixed processes.

However, you should know the limits. The initial cost is higher than field control. Energy efficiency is low because the resistor wastes power as heat. This method is not suitable for continuous operation. You may want to consider adding a dc speed controller for better efficiency in long-term use.

Aspect | Advantages | Limitations |

|---|---|---|

Control Accuracy | Nearly unmatched accuracy and control | |

Field Current and Torque | Constant throughout operation | |

Speed Variation | Fast and simple speed variation in both directions | |

Initial Cost | Higher initial costs compared to field control | |

Energy Efficiency | Low energy efficiency due to power loss during speed variation | |

Application Suitability | Best for short-duration or fixed processes, not continuous use |

Flux Control Method

Principle of Flux Variation

You can control the speed of a dc motor by changing the magnetic flux in the field winding. This method is called flux control. When you decrease the field current, the magnetic flux becomes weaker. As a result, the speed of the dc motor increases. If you increase the field current, the flux gets stronger and the speed drops. This technique gives you a simple way to adjust motor speed above its rated value.

The principle of flux variation is important in advanced motor control. For example, in Field-Oriented Control (FOC) and Direct Torque Control (DTC), you can separate the control of flux and torque. This separation helps you achieve fast speed changes and keeps the motor stable, even if the load or other conditions change. Researchers have shown that controlling the orientation of the magnetic flux improves speed regulation and reduces unwanted torque ripples. You can use sliding-mode control or other algorithms to keep the flux at the right level, even when there are disturbances or changes in motor parameters. This approach lets you reach your desired speed quickly and keeps the motor running smoothly.

💡 Tip: Always monitor the field current when using flux control. Too much reduction can cause the dc motor to overspeed, which may damage the machine.

Industrial Applications

You will find flux control used in many industrial applications where you need to adjust the speed of a dc motor above its base value. This method works well for fans, blowers, and pumps. These machines often run at variable speeds to match process needs. By using flux control, you can save energy and reduce wear on your equipment.

Recent research highlights how optimizing flux and torque control can improve performance in industrial environments. For example:

A hybrid control method can minimize losses and improve how the motor responds to sudden load changes.

Tuning the controller for flux and torque helps you keep the speed steady and reduces the time needed for adjustments.

You can achieve up to 20% energy savings by maintaining the right flux, even if you do not know the exact load in advance.

These methods also make real-time control easier, which is important for industrial drives that need precise speed control.

You can apply these ideas to dc motor systems. By managing the field current and monitoring the flux, you can keep your motor running efficiently and safely. This approach helps you meet your process goals and lower your energy costs.

PWM and Closed-Loop Motor Speed Control

PWM Technique

You can use pulse width modulation, or PWM, as the most efficient way to control dc motor speed. PWM works by turning the power to the dc motor on and off very quickly. You adjust the "duty cycle," which is the percentage of time the power stays on during each cycle. When you increase the duty cycle, the average voltage sent to the motor goes up, and the motor speed increases. When you lower the duty cycle, the speed drops.

PWM control gives you precise and smooth speed changes. You do not waste much energy as heat, so your system stays cool and efficient. Many modern trainer boards use PWM speed control to help you learn and experiment with different speed control settings. These boards include the motor, power supply, control circuits, and feedback sensors like tachometers or encoders. You can see how changing the duty cycle affects the motor speed in real time.

PWM lets you:

Adjust the average voltage to the dc motor without losing efficiency.

Keep the motor running at the right speed for your application.

Protect the motor from running too fast or too slow.

Extend the motor’s lifespan by avoiding stress from sudden voltage changes.

💡 Tip: Use PWM control for your dc electric motor if you want an efficient way to control dc motor speed in industrial settings.

Closed-Loop Feedback

Closed-loop feedback systems help you keep the motor speed steady, even when the load changes. You use sensors to measure the actual motor speed. The controller compares this speed to your target value. If there is a difference, the controller adjusts the PWM signal to correct the speed.

You can use different types of sensors, such as encoders or tachometers, to get accurate speed readings. The controller uses this feedback to make quick changes and keep the motor running at the desired speed. This method works well for applications where you need precise speed control, like conveyor belts, pumps, or robotic arms.

Here is how closed-loop feedback works step by step:

Set your desired speed.

The sensor measures the actual motor speed.

The controller compares the actual speed to the setpoint.

If the speeds do not match, the controller changes the PWM signal.

The motor speed adjusts until it matches the setpoint.

Closed-loop feedback systems use advanced controllers, such as PI (Proportional-Integral) or PID (Proportional-Integral-Derivative) controllers. These controllers help you get fast response times and stable operation. Recent tests show that using an EXP-PI controller gives you better speed tracking and less overshoot than a standard PI controller. You can see this in the table below:

Test Condition / Parameter | Controller Type | Observed Performance Metrics |

|---|---|---|

Step speed changes (0 to 1000 rpm, 2000 rpm, etc.) | EXP-PI vs. Conventional PI | Both track steady-state speed tightly; EXP-PI has less overshoot and faster settling time |

Complex speed trajectory | EXP-PI vs. Conventional PI | EXP-PI tracks speed closely; conventional PI sometimes loses stability |

System stability | EXP-PI controller | All system poles negative, confirming stability |

You can rely on closed-loop feedback to keep your dc motor running at the exact speed you need, even if the load or conditions change.

Benefits in Industrial Use

PWM and closed-loop feedback together give you the best results for dc motor speed control in industrial applications. You get high efficiency, precise speed regulation, and reliable operation. Many industries use this combination to save energy, reduce maintenance, and improve product quality.

The table below shows how PWM control and closed-loop feedback perform in real industrial tests:

Performance Metric | Value | Significance and Comparison |

|---|---|---|

Power Factor | 0.99 | Near-ideal power usage, better than other control methods. |

Total Harmonic Distortion (THD) | 1.12% | Low distortion, better power quality, less energy loss. |

Efficiency | 95% | High energy conversion, proven by experiments and simulations. |

Transmission Efficiency | 83.5% - 84.1% | Stable across different power levels, reliable for industrial use. |

You can also see big improvements in motor lifespan and system cost. For example, brushless dc motors with sensorless PWM feedback last up to three times longer than traditional motors. These motors run more efficiently and respond faster to changes in speed. Automotive fuel pumps and home appliances now use PWM speed control to get better performance and lower costs.

Key industrial benefits of PWM and closed-loop feedback:

Rapid response to speed changes.

Stable operation under different loads.

Lower hardware costs with digital controllers.

Improved current distribution and resilience to load changes.

Extended motor lifespan and reduced maintenance.

✅ Note: When you combine PWM with closed-loop feedback, you get the most efficient, reliable, and precise way to control dc motor speed in modern industry.

You can use PWM and closed-loop feedback for many applications, such as electric vehicles, robotics, pumps, fans, and conveyor systems. These methods help you meet strict industrial standards for efficiency, safety, and performance.

Comparing DC Motor Speed Control Methods

Method Comparison Table

You need to compare different dc motor speed control methods before you choose the best one for your automation project. Each method has unique strengths and weaknesses. The table below shows how these methods perform in terms of efficiency, cost, reliability, and suitability for automation.

Control Method | Efficiency | Cost | Reliability | Suitability for Automation | Maintenance Needs | Typical Applications |

|---|---|---|---|---|---|---|

Armature Voltage Control | High | Moderate | High | Excellent | Moderate | Conveyors, pumps, fans |

Armature Resistance Control | Low | Low | Moderate | Limited | High | Short-duration, fixed speed |

Flux Control | Moderate | Low | Moderate | Good | Low | Fans, blowers, variable speed |

PWM Control | Very High | Moderate | Very High | Excellent | Low | Robotics, EVs, automation |

Closed-Loop Feedback | Very High | High | Very High | Excellent | Low | Precision automation, robotics |

You can see that PWM and closed-loop feedback methods offer the best efficiency and reliability. These methods also work well for most automation tasks. Armature voltage control is a solid choice for many industrial automation systems. Armature resistance and flux control are better for simple or short-term uses.

You should also consider the type of dc motor you use. Brushed dc motors are easy to control and cost less, but they need more maintenance. Brushless dc motors give you higher efficiency and longer life, but they cost more and need advanced controllers. Permanent magnet synchronous motors offer the highest efficiency and smooth operation, but they require complex control and have a higher price.

Motor Type | Advantages | Limitations |

|---|---|---|

Brushed DC Motor (BDC) | Easy to use, high startup torque, low cost | Lower efficiency, more maintenance |

Brushless DC Motor (BLDC) | High efficiency, low maintenance, better heat | Higher cost, needs precise electronic control |

Permanent Magnet Synchronous Motor (PMSM) | Highest efficiency, compact, smooth operation | High cost, risk of demagnetization, complex |

📝 Tip: Choose a brushless dc motor with PWM and closed-loop feedback for the best motor performance in demanding automation environments.

Selection Guidelines

You need to match the control method to your application. Follow these steps to make the right choice for your dc motor speed control:

Define Your Application Needs

List your required speed range, torque, and response time.

Decide if you need precise speed regulation or just basic control.

Check Efficiency and Cost

Use PWM or closed-loop feedback for high efficiency and energy savings.

Pick armature voltage control if you want a balance between cost and performance.

Choose resistance or flux control for simple, low-cost setups.

Consider Reliability and Maintenance

Select brushless dc motors for low maintenance and long life.

Use brushed dc motors if you want lower upfront costs and can handle more maintenance.

Evaluate Suitability for Automation

Go with PWM and closed-loop systems for industrial automation and robotics.

Use simple voltage or resistance control for basic, non-critical tasks.

Review Real-World Performance Metrics

Look for features like fast response, low noise, and stable operation.

Advanced controllers such as adaptive PID or fuzzy logic can improve motor performance and efficiency.

Training systems like Amatrol’s SCR speed control let you test and measure real dc motor performance before full-scale deployment.

Follow Industry Guidelines

Use closed-loop PID control for precise speed regulation.

Apply PWM for efficient voltage control and noise reduction.

Consider advanced algorithms for applications needing high precision and adaptability.

⚡ Note: Always balance energy efficiency, speed accuracy, and maintenance when you select a control method for your dc motor. The right choice improves automation, saves energy, and extends equipment life.

Real-world performance metrics you should consider:

Torque control for precise speed regulation.

Efficiency for lower energy use and longer motor life.

Noise reduction from PWM frequency modulation.

Adaptability to changing loads and environments.

Industry guidelines recommend:

Closed-loop PID for precision.

PWM for efficiency and noise control.

Advanced algorithms for optimized automation.

Good thermal management and safety protocols.

You can use these guidelines to select the best dc motor speed control method for your automation project. Always match the method to your application’s needs, motor type, and environment. This approach ensures top performance and reliability in industrial automation.

You have learned about key DC motor speed control methods, such as armature voltage control, resistance control, flux control, PWM, and closed-loop feedback. Each method offers unique benefits for different industrial tasks. Always match your control method to your application’s needs for efficiency, cost, and precision.

🛠️ Tip: Review your process requirements before choosing a control method. If you feel unsure, consult a motor control expert to ensure safe and reliable operation.

FAQ

What is the easiest way to control DC motor speed in industry?

You can use PWM (Pulse Width Modulation) for easy and efficient speed control. PWM lets you adjust speed with simple digital signals. Many industrial controllers support this method.

How do you choose the right speed control method?

Start by listing your process needs. Check if you need high precision, low cost, or simple setup. Use a table to compare methods:

Need | Best Method |

|---|---|

High precision | Closed-loop PWM |

Low cost | Resistance control |

Simple setup | Voltage control |

Can you use one controller for different DC motors?

You can use one controller for similar motors. Always check the voltage and current ratings. If you use different motor types, you may need to adjust settings or use a universal controller.

How does closed-loop feedback improve speed control?

Closed-loop feedback uses sensors to measure speed. The controller compares this to your setpoint. If the speed changes, the controller corrects it. You get stable and accurate speed, even if the load changes.

See Also

Choosing The Best Mini DC Motors For Industrial Use

Guide To Picking The Ideal Rotate Motor For Industry

Seven Key Uses Of Vibration Motors To Boost Manufacturing

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry