Understanding Counter EMF in ERM Vibration Motors: Key Principles and Applications

Counter EMF, also called "back electromotive force," is important in motors like ERM vibration motors. It helps the motor work well by controlling itself. When the motor spins faster, counter EMF grows and reduces the current in the motor. This stops the motor from using too much power and keeps it safe. By keeping the current at good levels, counter EMF improves how the motor works and saves energy.

Key Takeaways

Counter EMF, also called back EMF, helps motors manage electricity. It makes them work better and stay cool.

When motors spin faster, counter EMF grows. This lowers electricity use and saves energy, especially in gadgets with batteries.

Knowing how load and counter EMF connect can make motors work better and use less energy.

Counter EMF helps control motors precisely. It adjusts speed and position without needing extra tools.

Checking counter EMF often can find problems early. This keeps motors working well and lasting longer.

Definition and Key Principles of Counter EMF

What is Counter EMF?

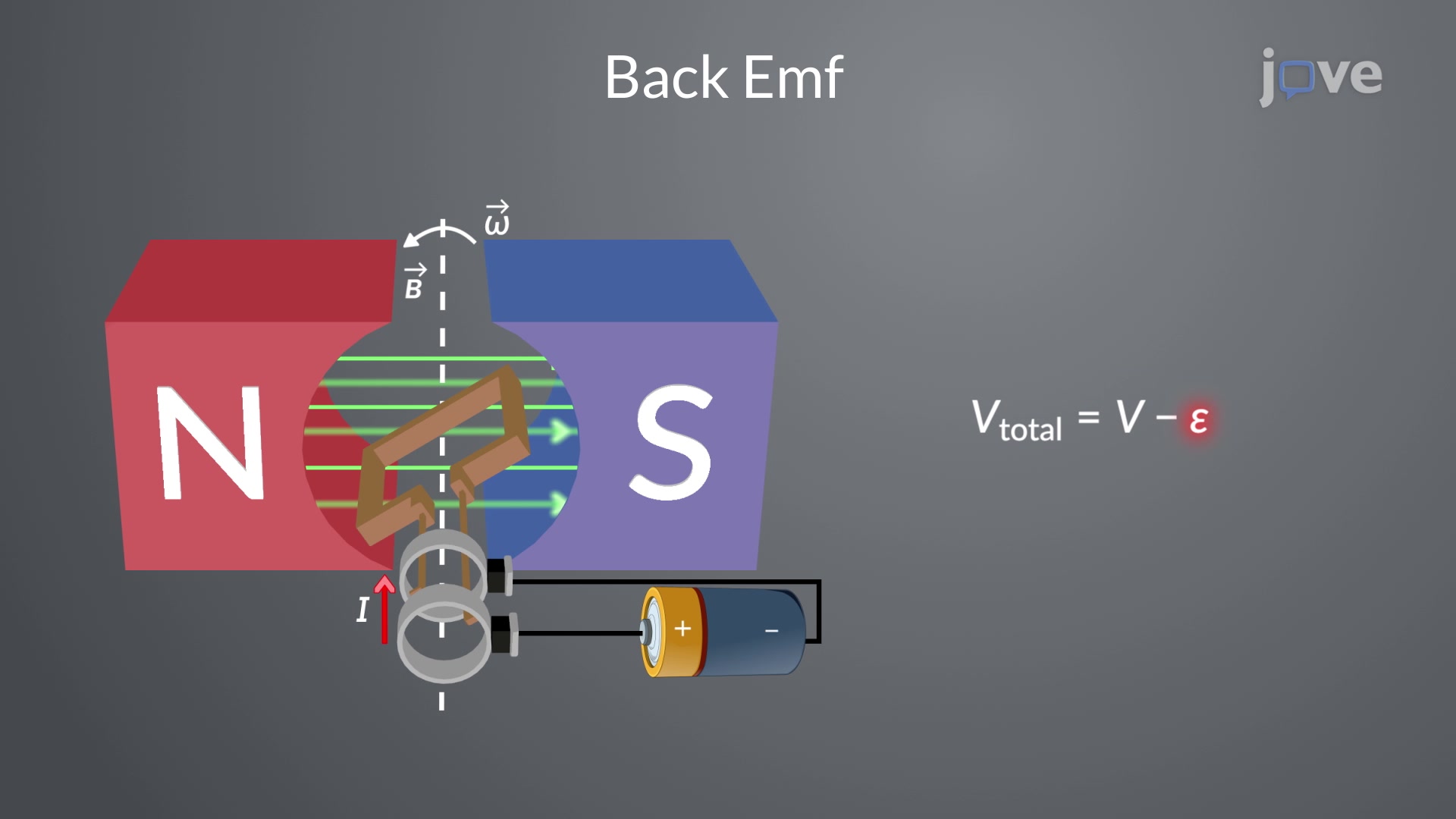

Counter EMF, or back EMF, is a voltage made by a motor. When the motor spins, its coils move through a magnetic field. This movement creates a voltage that pushes against the current. This happens because of electromagnetic induction, where magnets and wires create electricity. Think of counter EMF as the motor's way to control how much current flows.

Counter EMF and motor speed are closely connected. When the motor spins faster, counter EMF grows. This can be shown with the formula e = KEω. In this formula, e is counter EMF, KE is a constant, and ω is speed. Tests show that counter EMF rises steadily as speed increases. This helps explain how motors adjust their performance on their own.

Importance in ERM Vibration Motors

In ERM vibration motors, counter EMF is very important. These motors are used in phones, game controllers, and wearables for vibrations. Without counter EMF, the motor might use too much current and overheat. Counter EMF creates an opposite voltage to limit the current and protect the motor.

Counter EMF also helps the motor work accurately. For example, in devices needing steady vibrations, counter EMF keeps the motor stable. It adjusts the motor as speed or load changes, keeping vibrations even. This makes ERM motors dependable for many uses.

Connection to Motor Efficiency

Counter EMF improves how well a motor uses energy. It pushes against the input voltage, lowering the current in the coils. This saves energy and reduces heat loss, making the motor more efficient. In battery-powered devices like phones, this means longer battery life.

The link between counter EMF and speed helps the motor adapt. At higher speeds, counter EMF limits current naturally. This stops wasted energy and keeps the motor efficient at different speeds and loads.

How Counter EMF Works

Physics of Counter EMF

Counter EMF, or back EMF, happens because of electromagnetic induction. When an ERM motor spins, its coils meet a magnetic field. This creates a voltage that pushes against the current. Faraday’s Law explains this. It says the voltage equals how fast the magnetic flux changes.

To understand better, check the table below:

Principle | Explanation |

|---|---|

Induced EMF | Voltage depends on how fast magnetic flux changes. |

Changing Magnetic Flux | Current appears only when flux through the loop changes. |

Direction of Induced Field | The new field fights the original changing magnetic field. |

Faraday’s Law | Inductors resist current changes by making counter-current. |

These ideas show why counter EMF controls current in ERM motors. Faster spinning makes more EMF, which limits current and saves energy.

Magnetic Fields and Motor Coils

Magnetic fields and motor coils work together to create counter EMF. Moving coils through a magnetic field makes EMF. Experiments show this clearly. Push a magnet into a coil, and EMF appears. Pull it out, and EMF reverses. Faster movements make stronger EMFs. Still magnets make none.

Try this experiment yourself:

Get a bar magnet and copper wire.

Wrap the wire into a coil with 10–20 loops.

Attach the coil to a galvanometer.

Move the magnet near the coil and watch the readings.

This experiment shows why motion between magnets and coils matters. It also explains how ERM motors use changing magnetic fields to make back EMF.

Role of Rotational Speed

Rotational speed affects counter EMF in ERM motors. Faster spinning means coils cut the magnetic field quicker. This raises the flux change rate, making stronger EMF. The formula EMF = -L(ΔI/Δt) shows this link. Faster speeds mean more back EMF.

In real life, this makes motors more efficient at high speeds. Back EMF limits current, saving energy and reducing heat. This self-adjusting system keeps motors running well under different loads and speeds.

Factors That Affect Counter EMF

Motor Speed

How fast a motor spins changes the back EMF it makes. Faster spinning means the coils cut the magnetic field quicker. This raises the magnetic flux change, making more back EMF. Think of it as the motor slowing the current as it speeds up. This helps the motor save energy and avoid using too much power.

For example, in ERM vibration motors, faster spinning creates more back EMF. This keeps the motor from overheating or wasting energy. Knowing this connection helps you understand how motors work at different speeds.

Load and Resistance

The weight or load on a motor changes its back EMF. A heavy load needs more power, which slows the motor down. Slower spinning lowers back EMF, letting more current flow to give extra power.

If the load is light, the motor spins faster and makes more back EMF. This reduces current and saves energy. By balancing the load, you can make the motor work better and use less power.

Magnetic Field Strength

The strength of the motor's magnetic field affects back EMF. Stronger magnets make more back EMF by boosting the coil and flux interaction. Motors with strong magnets control current better.

Weak magnetic fields lower back EMF, allowing more current to flow. This wastes energy and can overheat the motor. Keeping the magnetic field strong helps the motor work well and stay reliable.

Applications of Counter EMF in ERM Vibration Motors

Motor Control and Precision

Counter EMF helps ERM motors control speed and position better. It lets the motor adjust itself without needing extra sensors. This feedback allows precise changes to how the motor works. For example, advanced systems use counter EMF to guess rotor speed and position. These systems use smart methods like EKF observers to improve accuracy. Modern processors make these methods faster and more dependable.

Here are some ways counter EMF improves motor control:

Using counter EMF to estimate speed and position without sensors.

Applying EKF observers for better motor performance modeling.

Adding advanced processors to handle complex control tasks.

Studies compare how counter EMF works in different motor designs. The table below shows key methods and their results:

Strategy | Description | Performance Insights |

|---|---|---|

Strategy 1 | Method 1 overview | Helps with precise motor control |

Strategy 2 | Method 2 overview | Works well under changing conditions |

Strategy 3 | Method 3 overview | Improves speed guessing accuracy |

Strategy 4 | Method 4 overview | Reliable in real-world uses |

These methods show how counter EMF makes ERM motors accurate and dependable. This makes them great for tasks needing steady performance.

Energy Efficiency

Counter EMF helps ERM motors save energy by controlling current flow. When the motor speeds up, counter EMF grows and lowers the current. This stops the motor from wasting energy or overheating.

For example, in battery-powered devices like phones, counter EMF keeps the motor efficient. It reduces extra current use, saving battery life and cutting energy waste. This is very useful for portable devices where saving power matters.

Counter EMF's ability to save energy makes it important for designing motors. Whether in gadgets or machines, it lowers costs and helps the environment.

Haptic Feedback in Consumer Electronics

Counter EMF improves ERM motors used for vibrations in electronics. Devices like phones and game controllers use these motors for touch feedback. Counter EMF keeps the motor steady, making vibrations smooth and reliable.

For instance, when your phone vibrates for a message, counter EMF ensures the vibration feels even. This is especially important for gaming, where good feedback improves the experience.

By using counter EMF, companies can make devices with better vibration quality. This shows how counter EMF helps modern technology give users a better experience.

Practical Considerations for Counter EMF

Challenges in Motor Design

Making a motor use back EMF well is tricky. You must balance speed, load, and magnetic strength for good performance. For example, high speeds increase back EMF, limiting current flow. But too much back EMF can make it hard to handle sudden loads. Weak back EMF, however, may cause overheating and waste energy.

Choosing the right materials is also important. Strong magnets create better back EMF. Poor-quality magnets weaken it, lowering motor efficiency. Small motors, like those in gadgets, need careful design. Engineers must balance size and performance perfectly.

Optimization Tips

To improve back EMF in motors, follow these tips:

Use genetic optimization to improve motor designs. This means testing many designs and picking the best ones.

Try crossover and mutation methods to make designs better. These help motors create and control back EMF more effectively.

Focus on motor types like Axial Flux or Hub BLDC motors. These motors are known for being efficient and powerful.

These steps help motors work better by controlling back EMF. This improves how reliable and efficient they are.

Monitoring and Testing

Testing motors is key to making sure they work well. Tools like oscilloscopes can measure back EMF under different conditions. For instance, testing at various speeds and loads shows how back EMF changes. This helps you decide if adjustments are needed.

Regular testing finds problems like overheating or wasted energy. Watching back EMF lets you fix issues early. This keeps the motor reliable and efficient for a long time.

Knowing about counter EMF helps motors work better. It controls current flow to keep motors efficient and safe. For ERM vibration motors, counter EMF stops energy waste and overheating. This makes them great for portable gadgets.

Different motor designs show how counter EMF changes performance. Check the table below for examples:

Motor Type | Peak Back EMF | Sine Wave Match | Harmonics Found |

|---|---|---|---|

18-slot–8-pole PMSM | Lower | Less accurate | 3rd harmonic |

24-slot–10-pole PMSM | Highest | Most accurate | None |

30-slot–10-pole PMSM | Lowest | Least accurate | 5th and 7th harmonics |

When building motors, focus on counter EMF. It boosts efficiency and makes motors last longer. This leads to better and stronger systems.

FAQ

What does counter EMF do in vibration motors?

Counter EMF controls the current in motors. It helps motors work well by saving energy and stopping overheating. In vibration motors, it keeps vibrations steady for things like phone feedback.

How does counter EMF make haptic feedback better?

Counter EMF keeps motor speed and vibrations steady. This makes touch feedback more accurate, improving how devices like phones and game controllers feel to use.

Why does counter EMF help save energy?

Counter EMF stops extra current from flowing in motors. This saves energy and reduces heat, making gadgets like vibration motors last longer on batteries.

Can counter EMF change how gaming feels?

Yes, counter EMF keeps vibrations steady in gaming devices. This makes games feel more real and improves how fast and accurate the feedback is.

How does counter EMF work with magnets?

Counter EMF happens because of electromagnetic induction. When motor coils move through a magnetic field, they make a voltage that pushes back. This helps vibration motors work smoothly and reliably.

See Also

Exploring Motor Diagrams: Components, Types, And Uses In ERM Vibration

Battery-Powered Motors: Varieties, Uses, And Efficiency For ERM Vibration

Understanding Vibration Motors: Varieties, Uses, And Mechanisms

Motor Brushes: Key Elements For ERM Vibration Motor Functionality

Fundamentals Of Frequency Vibration: Engineering For Coin Motor Design

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry