Coreless DC Motors vs Cored and brushless DC Motors

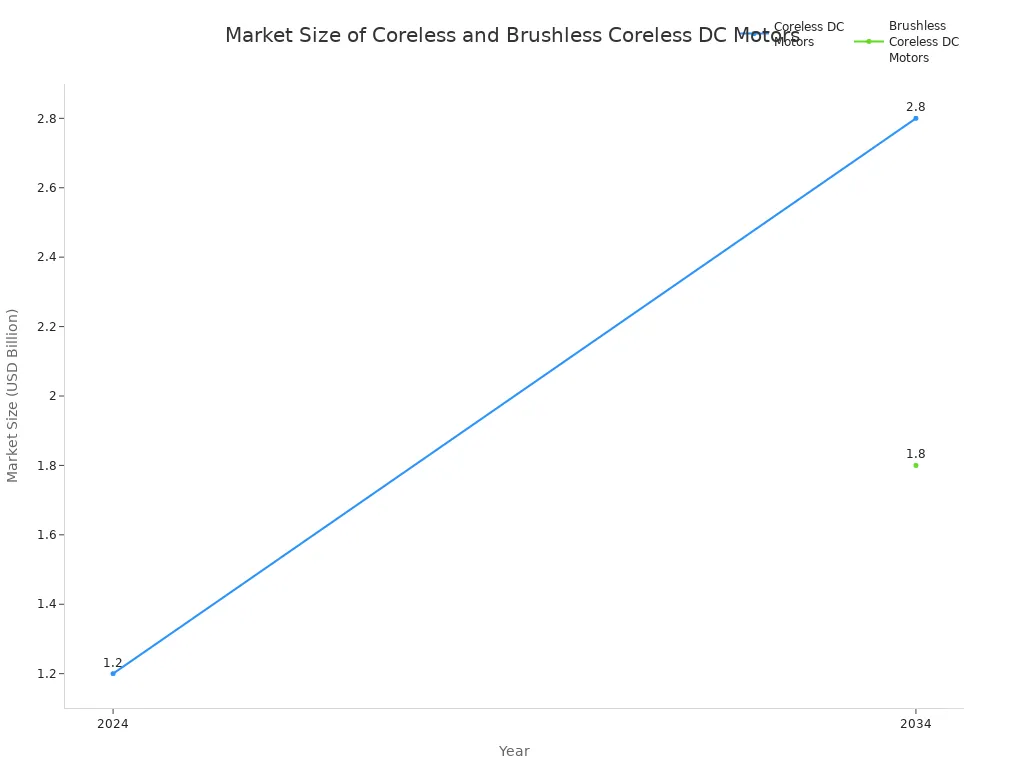

Choosing the right electric motor depends on what you need. Coreless dc motors work well in medical devices, robots, and tools. They are light and use energy well. Brushless dc motors are used in electric cars and machines. They last a long time and do not need much care. Cored dc motors are still used in toys and power tools. They are simple and work well. The chart below shows that coreless and brushless coreless dc motors are growing fast. This is happening in electronics and factory machines.

Key Takeaways

Coreless DC motors are light and quick. They work well in devices that need to be exact, like medical tools and robots.

Cored DC motors give strong power and torque. They are good for simple things like toys and power tools. But they do not work as well as other types.

Brushless motors last the longest and save the most energy. They use electronic controls and do not have brushes. This makes them good for electric cars and drones.

You should pick the right motor for your needs. If you want speed and accuracy, choose coreless. If you need strong power, choose cored. If you want a motor that lasts long and needs little care, choose brushless.

Always make sure the motor’s size, speed, and power fit your device. This helps your device work well and last longer.

Coreless DC Motors

Structure

Coreless dc motors have a special hollow rotor. The rotor is shaped like a cup or a cylinder. It is made from tightly wound copper coils. There is no iron core inside the rotor. This makes the rotor much lighter than usual. The lighter rotor has less inertia. The coils hold themselves together and are made stronger with epoxy. The stator uses permanent magnets to make a magnetic field. Air can move over both sides of the coils. This helps keep the motor cool. The table below shows how coreless dc motors are different from regular motors:

Feature | Coreless DC Motor | Conventional DC Motor |

|---|---|---|

Rotor Design | Hollow coil, no iron core | Solid iron core |

Inertia | Low | High |

Cogging Effect | Minimal or none | Present |

Efficiency | Higher | Moderate |

Speed Response | Fast | Slower |

How They Work

Coreless dc motors work like other electric motors. Brushes and the commutator send current through the rotor windings. Permanent magnets in the stator make a magnetic field. When current goes through the coils, it makes a force. This force spins the rotor. Without an iron core, the rotor is lighter. It can speed up or slow down very fast. This is good for things that need quick control, like robots or medical tools. The design helps save energy. The motor runs smoothly and does not make much noise.

Key Features

Coreless dc motors have many good points. They are very efficient, sometimes up to 80%. Their low inertia lets them speed up and slow down quickly. These motors can go as fast as 35,000 rpm. They are light and do not make much noise or shake. This makes them good for delicate equipment. But they can get too hot if used too hard for too long. The small space between the stator and rotor can trap heat. So, cooling is important. Coreless motors use brushes that can wear out. The brushes may need to be replaced after some time. Taking care of the motor and not overloading it helps it last longer.

Cored DC Motors

Structure

Cored DC motors have a rotor with an iron core inside. Wires are wrapped around this iron core. The iron core helps make the magnetic field stronger. This design lets the motors make more torque for their size. The iron core adds extra weight and makes the rotor harder to move. Because of this, the motors need more power to start and stop. The iron core can also get hot and waste energy. This makes the motor less efficient. The table below shows how cored DC motors and coreless DC motors are different:

Aspect | Cored DC Motors | Coreless DC Motors |

|---|---|---|

Rotor Construction | Coils wound around an iron core | Self-supporting windings without an iron core |

Magnetic Flux Behavior | Iron core enhances magnetic flux and torque | Magnetic field generated solely by windings |

Inductance | Higher due to iron core | Lower inductance |

Inertia | Higher due to iron core mass | Reduced inertia |

Losses | Eddy currents and hysteresis losses present | Reduced losses, less heat generation |

Efficiency | Lower due to core losses | Improved efficiency |

Performance | Standard torque production and motor regulation | Better for high acceleration and efficiency applications |

Operation

Cored DC motors work when electricity flows through the armature windings. The iron core in the rotor makes the magnetic field stronger. This helps the motors make more torque. Brushes and the commutator change the direction of the current. This keeps the rotor spinning around. The amount of torque depends on the current in the armature. You can control the speed by changing the voltage or current. The iron core causes some energy to be lost as heat. This happens because the magnetic field keeps changing. These motors also have a cogging effect. This makes it harder to control the motor smoothly at low speeds.

Characteristics

Cored DC motors have many reasons why people use them:

The iron core lets the motors make high torque, which is good for heavy loads.

These motors are cheap and last a long time, so they are good for simple jobs.

They work well in machines, vehicles, and home appliances.

The motors can use regenerative braking to save energy or dynamic braking to stop safely.

Different wiring types, like shunt or series, help control speed and torque.

But these motors need more care because the brushes and commutator wear out. They are not as efficient as coreless motors. The extra weight and heat from the iron core make them less useful for fast or very precise jobs. Still, cored DC motors are popular for jobs that need steady power and strong starting torque. Many people pick these motors because they are reliable and not expensive at first.

Brushless Motors

Design

Brushless motors are built differently from brushed motors. Brushed motors have windings and a commutator on the rotor. Carbon brushes touch the commutator to send electricity. This causes friction and makes the parts wear out. Brushless motors put permanent magnets on the rotor instead. The windings are in the stator. There are no brushes or commutator in these motors. An electronic controller changes the current in the stator windings. This setup helps brushless motors run quietly and last longer. Many brushless motors are flat and small. This helps them fit inside thin devices.

Component | Brushed DC Motor | Brushless DC Motor (BLDC) |

|---|---|---|

Stator | Permanent magnets | Stationary windings (coils) |

Rotor | Wound coils | Permanent magnets |

Commutator | Segmented ring for switching | None (uses electronics) |

Brushes | Carbon contacts | None |

Commutation | Mechanical | Electronic |

How They Work

Brushless motors use electronics to control how they spin. Sensors, like Hall effect sensors, find out where the rotor is. The controller uses this to change the current in the stator windings. This makes a moving magnetic field that turns the rotor. This way, there is no need for brushes or a commutator. Using electronics gives better control of speed and torque. It also means less friction, noise, and wear. Because of this, brushless motors can spin faster and last longer than brushed motors.

Tip: Using electronics to switch the current helps brushless motors work quietly and use less energy. This is good for delicate equipment.

Main Benefits

Brushless motors have many good points over brushed motors. They are very efficient, usually between 85% and 90%. Some can even go above 96%. No brushes means less fixing and fewer parts to change. Brushless motors can work for up to 10,000 hours or more. They make less heat and shake less, so they last longer. These motors also let you control speed and torque very well. Many industries use brushless motors in electric cars, robots, medical tools, and home devices. Their long life and low need for fixing make them a smart pick for many uses.

Benefit | Details |

|---|---|

Efficiency | 85%-96%, saves energy and reduces costs |

Lifespan | Up to 10,000 hours, fewer moving parts |

Maintenance | Low, no brushes or commutators to replace |

Extra | Less vibration, better cooling, precise control, compact design |

Coreless Motors vs Cored and Brushless

Performance

Coreless motors have a hollow rotor with no iron core. This makes them very light. Because they are light, they speed up and slow down quickly. They are great for jobs that need fast and smooth moves, like robots or medical tools. Brushless motors use electronics to control them. These controls help them speed up the fastest. They also have the best response time. Slotless brushless motors shake less and can be controlled very well. Cored motors have an iron core inside. The iron core makes them heavier. Heavy motors cannot speed up as fast as coreless or brushless motors. Cored motors are best when you need strong power more than speed.

Note: Brushless motors speed up and react the fastest. Coreless motors come next. Cored motors are the slowest for speed and reaction.

Motor Type | Acceleration & Speed | Response & Control Characteristics |

|---|---|---|

Coreless DC | Light, fast, smooth | Quick reaction, needs careful speed changes |

Cored (Brushed) | Slower, heavier | Slow reaction, less exact control |

Brushless (BLDC) | Fastest, smoothest | Best reaction, very exact electronic control |

Efficiency

Efficiency means how well a motor uses electricity to do work. Coreless dc motors are about 78% efficient in normal use. Their hollow shape helps them stay cool and waste less energy. Brushless motors are even better, sometimes up to 96% efficient. They do not have brushes, so they lose less energy from rubbing parts. Cored motors lose more energy as heat because of the iron core. The iron core causes extra energy loss, so these motors are not as efficient. People pick brushless motors when they want to save the most energy. Coreless motors are good when size and weight are important, but they still work well.

Applications

People pick different motors for different jobs.

Coreless dc motors are best for things that need to move fast, be light, and be exact. They are used in medical pumps, small robots, and hand tools. Their low inertia helps them start and stop quickly.

Cored motors are good for jobs that need steady power and strong force. They are used in toys, power tools, and machines that do not need to change speed quickly.

Brushless motors are great where long life, little fixing, and high efficiency are needed. They power electric cars, drones, and factory machines. Their electronic controls make them perfect for smooth and quiet work.

Tip: If you need the fastest reaction and little fixing, pick brushless motors. For light and exact work, coreless motors are best. For simple and strong jobs, cored motors are a good choice.

Quick-Reference Comparison Table

Feature | Coreless DC Motors | Cored DC Motors | Brushless Motors |

|---|---|---|---|

Acceleration | Fast, smooth | Slow | Fastest, very smooth |

Efficiency | High (~78%) | Lower | Highest (up to 96%) |

Maintenance | Brushes wear, needs care | Frequent brush care | Very low, no brushes |

Lifespan | Moderate | Shorter | Longest |

Cost | Affordable, mid-range | Lowest | Highest (electronics cost) |

Best Use | Precision, light devices | High torque, simple jobs | Long life, high efficiency |

Choosing the Right Motor

Selection Tips

Picking the right motor depends on many things. Every motor type has good and bad points. People should think about why a motor is best for their job before picking one.

Saving energy is important for some jobs. Brushless motors use energy best and last the longest.

Medical tools and robots need to be light and exact. Coreless dc motors are best here because they are light and move smoothly.

Price matters for many people. Brushed motors cost less and are simple, but they break down faster and need more fixing.

How much care a motor needs is important. Brushless motors do not need much care. Brushed motors need new brushes often.

Some jobs need strong power or fast speed. Cored motors are strong for heavy work. Brushless motors are best for fast moves and quick starts.

Where the motor works can change how well it works. Motors made for tough places last longer and work better.

Tip: Always make sure the motor’s voltage and size fit the device’s power and space.

Application Guide

Different jobs need different motor features. The table below shows which motor is best for each job:

Application Area | Best Motor Type | Why This Motor? |

|---|---|---|

Medical Devices | Coreless DC | Needs precision, low weight, and smooth motion |

Robotics | Coreless DC | Fast acceleration and accurate control |

Drones, EVs | Brushless | High efficiency, long life, low maintenance |

Power Tools, Toys | Cored (Brushed) | Low cost, simple control, strong torque |

Industrial Automation | Brushless | Quiet, reliable, and efficient operation |

People should think about how long and where the motor will run. If a motor runs all the time in hot or shaky places, it needs to be strong and handle heat. Sometimes, a special motor is needed if normal ones do not work for the job.

Picking the right motors depends on what the job needs. Some jobs need speed, some need to save energy, and some need the motor to last a long time. Brushless motors are best when you want high efficiency and little fixing. They are good for drones and electric vehicles. Coreless motors are great for jobs that need to be exact and light. They work well in medical devices because they react fast. Cored motors are good for simple and strong jobs. They are used in toys and power tools.

Always make sure the motor’s speed, torque, and how long it runs match the job for the best results.

FAQ

Why do engineers choose coreless DC motors for precision devices?

Coreless DC motors can start and stop very fast. This helps engineers make devices move smoothly and accurately. Medical pumps and small robots need this kind of control.

Tip: Low inertia lets the motor change speed quickly.

Why do brushless motors last longer than brushed motors?

Brushless motors do not have brushes or commutators. This means there is less rubbing and less wearing out. Because of this, brushless motors stay cooler and work for more years.

Why do cored DC motors work well in heavy-duty tools?

Cored DC motors have iron cores that give extra torque. This extra power helps tools and machines lift or move heavy things. The strong magnetic field from the iron core makes these motors good for hard jobs.

Why do coreless motors overheat more easily?

Coreless motors are small and have less material to hold heat. If they run for a long time or work too hard, they can get hot. Without enough cooling, the motor can overheat.

Why do brushless motors cost more than brushed motors?

Brushless motors need special electronic controllers to work. These controllers make the price higher. The better design and longer life also make brushless motors cost more at first.

See Also

Differences Between Brushed And Brushless 3V Motors Explained

Why Investing In Mini Brushless Motors Benefits Precision Tasks

How To Select Battery Powered Motors For Best Performance

Choosing The Best Mini DC Motors For Industrial Use

Understanding The Main Differences Between Vibro And Standard Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry