Step-by-Step Guide to Controlling a Brushless DC Motor: Circuit Design and Implementation

A brushless DC motor (BLDC) is a special electric motor that excels in efficiency. By utilizing electronics instead of brushes, it significantly reduces friction and wear, achieving an efficiency rate that is 80 to 90% better than older brushed motors. This efficiency is crucial for applications such as electric cars, where BLDC motors power features like moving seats and mirrors.

Controlling a brushless DC motor requires circuit design skills. BLDC motors rely on electronic switches to manage power and speed effectively. Without well-designed circuits, the motor may not operate optimally or have a long lifespan. Engineers implement techniques like trapezoidal or sinusoidal switching to enhance performance, ensuring that the motor runs smoothly and conserves energy.

This guide will teach you the essentials of controlling a brushless DC motor. It will cover both circuit design and software programming. Whether your interest lies in robotics or automotive applications, you’ll gain valuable insights to help you succeed.

Key Takeaways

Brushless DC motors (BLDC) work very efficiently, saving energy up to 95%. They are great for things like electric cars.

BLDC motors last longer and need less fixing because they don’t have brushes like older motors.

Picking the right control method changes how the motor works. Trapezoidal control is easier, but sinusoidal control makes the motor run smoother.

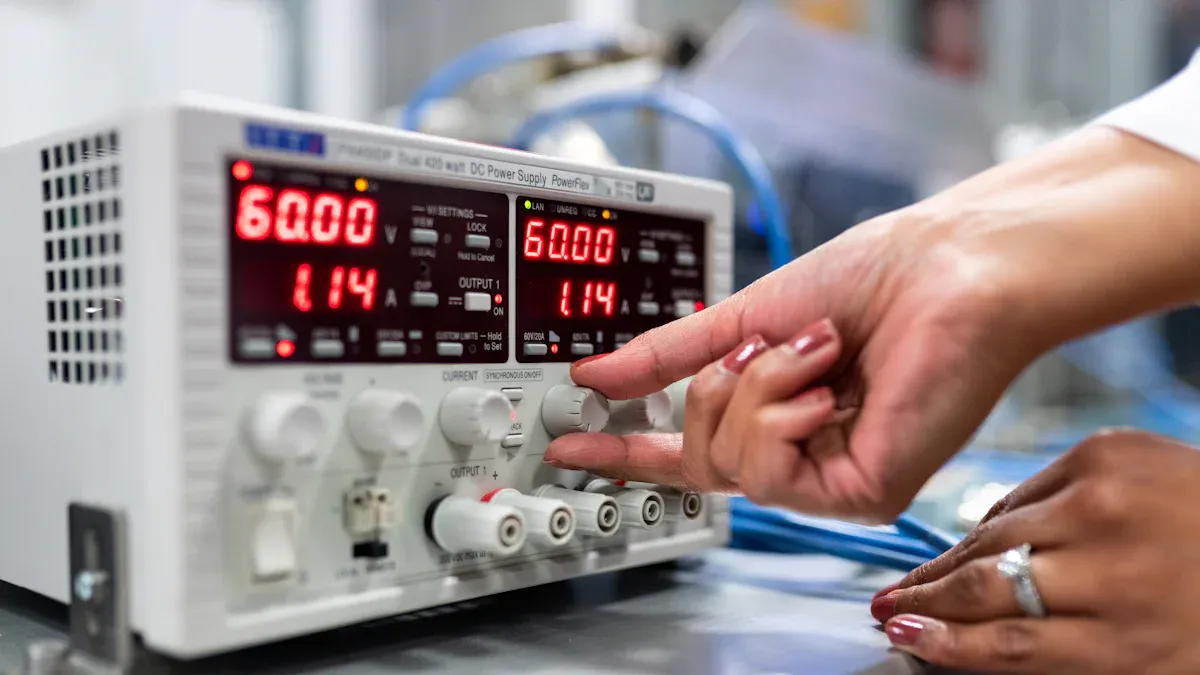

Good circuit design is important for controlling BLDC motors. Choose the right parts and set voltage and current carefully.

Testing and fixing firmware is key for making the motor work well. Start with easy tests, then move to harder ones.

Advantages of Controlling a Brushless DC Motor

High Efficiency and Reliability

Brushless DC motors (BLDC) work very efficiently and reliably. They turn electricity into motion with little energy wasted, reaching efficiency levels of 90% to 95%. This makes them great for saving energy in things like electric cars and factory machines.

These motors don’t use brushes, which often wear out in older motors. Without brushes, they are less likely to break and can work well for a long time. Below is a table comparing BLDC motors to other types of motors:

Motor Type | Efficiency (%) | Torque Density | Control Flexibility | Maintenance Requirements |

|---|---|---|---|---|

BLDC | 90-95 | High | High | Low (brushless) |

Brushed DC | 75-85 | Moderate | Moderate | High (requires brushes) |

Permanent Magnet Synchronous | 92-98 | High | Moderate | Low |

Induction | 85-90 | Moderate | Low | Moderate |

Low Maintenance and Durability

BLDC motors need very little care compared to brushed motors. Since they don’t have brushes or commutators, fewer parts wear out over time. To keep them working well, you just need to use them in clean places and avoid overheating.

You should check the bearings and electronics sometimes, but this is much less work than maintaining brushed motors. BLDC motors last a long time, making them a smart choice for robots and air systems.

No brushes or commutators to replace

Very low maintenance needs

Long-lasting and durable

Compact Design and High Power Density

BLDC motors are small but can produce a lot of power. This makes them useful for tight spaces like drones or medical tools. They use light materials, smart designs, and advanced controls to work efficiently.

For example, a BLDC motor can be only 85 mm wide but still give up to 12 kW of power and 22 N·m of torque. These motors also have built-in processors for better control and cooling systems like water cooling.

Specification | Details |

|---|---|

Diameter | 85 mm |

Maximum Output Power | Up to 12 kW |

Maximum Torque Output | Up to 22 N·m |

Speed | Up to 12,348 rpm |

Protection Level | IP68 |

Cooling Solution | Water cooling |

BLDC motors are small, powerful, and useful for many engineering tasks.

Fundamental Principles of BLDC Motor Control

Knowing how to control a BLDC motor is important. It helps create systems that work well and last long. The main ideas include sensing rotor position, controlling winding current, and switching techniques. These ensure the motor runs smoothly and efficiently.

Rotor Position Sensing Techniques

To control a BLDC motor, you must know where the rotor is. This tells you when to power the motor's windings. There are two ways to sense the rotor's position: using sensors or sensorless methods.

Hall-effect Sensors:

These sensors are inside the motor and detect the rotor's magnetic poles. They give accurate position data and are widely used. But they can make the motor more expensive and complex.Sensorless Control:

This method skips physical sensors and uses back electromotive force (BEMF) to find the rotor's position. It costs less and works better in tough conditions where sensors might fail.Miniaturized Sensors:

New small sensors, like vertical Hall sensors, are now available. They make motor control easier and more precise by providing phase-shifted signals.

Technique | Description |

|---|---|

Hall-effect sensors | Detect rotor position using magnetic poles inside the motor. |

Sensorless control methods | Use BEMF to find rotor position without physical sensors, saving costs. |

Miniaturized sensors | Compact sensors like vertical Hall sensors simplify control and improve accuracy. |

Picking the right sensing method helps balance cost, reliability, and performance.

Winding Current Control Methods

Managing the current in the motor's windings is key. It keeps the motor's torque steady and ensures it runs efficiently. The current creates the magnetic field that moves the rotor. Here are the main ways to control it:

Current Measurement:

Measuring winding current lets you adjust the motor's performance. This is useful for tasks needing exact torque control.Pulse Width Modulation (PWM):

PWM controls current by quickly turning power on and off. It adjusts voltage to the windings, allowing fine control of speed and torque.Field Oriented Control (FOC):

FOC, also called sinusoidal driving, is an advanced way to manage current. It improves torque and reduces noise. Though it needs better hardware, it’s more efficient than simpler methods.

Principle | Description |

|---|---|

Driving Methods | Two types: Trapezoidal and Sinusoidal (FOC), with FOC being more advanced. |

Rotor Position Measurement | Done using Hall sensors or BEMF for sensorless control. |

Winding Current | Important for keeping torque steady and maintaining magnetic strength. |

Learning these methods helps you control the motor precisely and boost system efficiency.

Commutation and Switching Basics

Commutation switches current in the motor's windings to keep the rotor moving. In BLDC motors, this is done electronically, unlike brushed motors that use physical brushes. Here are the main switching methods:

Square-wave Control:

This method uses Hall sensors or sensorless algorithms to find rotor position. Current switches six times per rotation, creating a trapezoidal waveform. It’s simple and cheap but less efficient and causes more torque ripple.Sine Wave Control:

This method creates smooth, three-phase sine wave voltage. It reduces noise and torque ripple, making the motor quieter. However, it needs advanced controllers.Field Oriented Control (FOC):

FOC manages current vectors for the best torque output. It’s highly efficient and quiet but requires better hardware and costs more.

Tip: For high-performance systems, choose FOC for its precision and efficiency.

Comparison of Techniques:

Square-wave control: Easy and low-cost, but less smooth.

Sine wave control: Quiet and efficient, but needs advanced tools.

FOC: Best for top performance, though more expensive.

Understanding these switching methods helps you pick the best one for your needs.

Driving Methods for BLDC Motors

Trapezoidal Drive: Features and Use Cases

Trapezoidal drive is a simple way to control BLDC motors. It uses square-shaped waves to power the motor's windings. Only two motor phases work at the same time. This lowers energy loss and makes the control easier. It’s a cheaper option for systems that don’t need smooth motion.

This method is common in tools and small electric vehicles. These devices focus on being simple and affordable, not precise. But trapezoidal drives can cause uneven torque and louder noise. Even with these issues, they are still widely used for basic motor control.

Sinusoidal Drive: Features and Use Cases

Sinusoidal drive is a more advanced way to control motors. It creates smooth waves to power the motor's windings. This removes uneven torque and makes the motor quieter and more efficient. It also gives the motor its strongest torque, which is great for high-performance tasks.

Sinusoidal drives are used in robots, drones, and medical machines. These systems need smooth and accurate motion. While this method is harder to set up and needs faster switching, it works well in tough situations.

Comparing Trapezoidal and Sinusoidal Drives

Picking between trapezoidal and sinusoidal drives depends on your needs. Trapezoidal drives are simpler and cheaper but make more noise and uneven torque. Sinusoidal drives are smoother and more efficient but need better hardware and software.

Here’s a comparison table to help you choose:

Specification | Sinusoidal Drive | Trapezoidal Drive |

|---|---|---|

Efficiency | Higher | Lower |

Noise Levels | Quieter | Louder |

Phase RMS Current | 0.74 * Id | 0.8165 * Id |

Current Reduction | ~10% lower | N/A |

Operational Complexity | More complex | Simpler |

Below are the pros and cons of each method:

Feature | Trapezoidal Control | Sinusoidal Control |

|---|---|---|

Advantages | Easy to control | No uneven torque |

Two phases active at once | Smooth motion | |

Lower energy loss | Strongest torque | |

Disadvantages | Uneven torque during switching | Higher energy loss |

Less torque produced | Harder to set up | |

Louder noise |

Knowing these differences helps you pick the right method for your motor system.

Circuit Design for Controlling a Brushless DC Motor

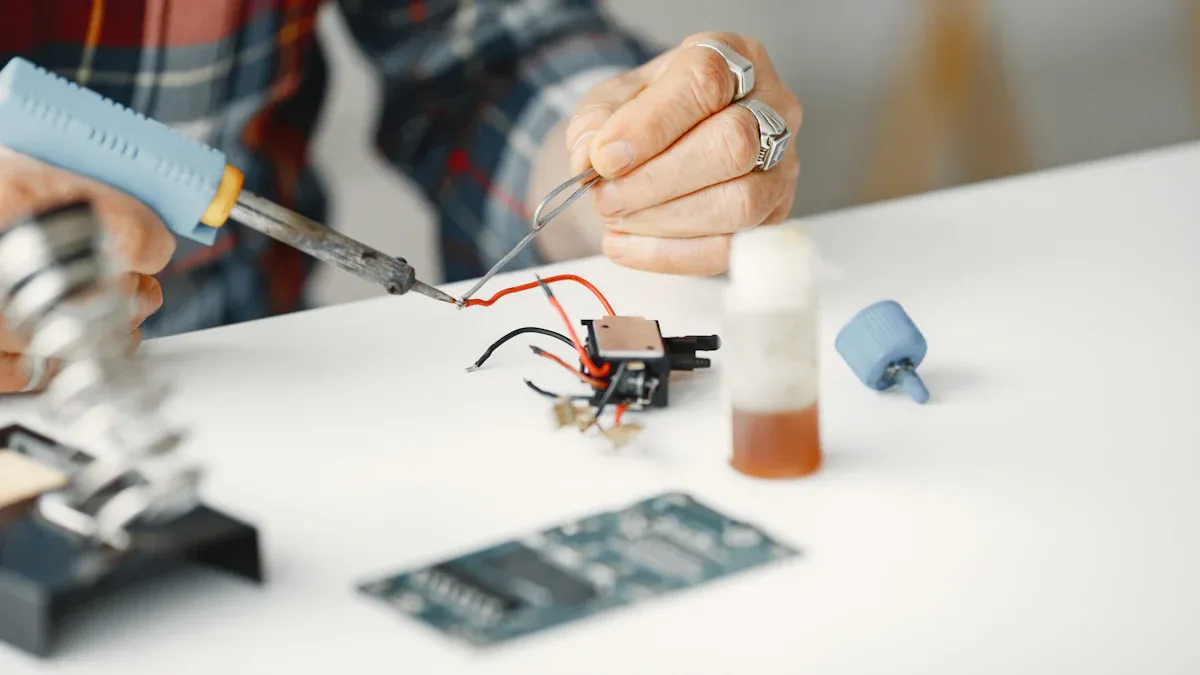

Making a circuit to control a brushless DC motor means picking the right parts, handling important settings like offset voltage and deadtime, and designing a strong PCB layout. Each step helps the motor work well and last longer.

Key Parts: Controllers, Power Stages, and Gate Drivers

To control a BLDC motor, you need three main parts: the controller, the power stage, and the gate driver. Each has a special job in the system.

Controller:

The controller is like the brain. It takes inputs like speed and rotor position and turns them into control signals. Microcontrollers with PWM modules are often used. For advanced tasks, digital signal processors (DSPs) can handle precise methods like Field Oriented Control (FOC).Power Stage:

The power stage manages the high current and voltage needed for the motor. It uses MOSFETs or IGBTs in a three-phase bridge setup. These parts switch current to the motor based on signals from the controller.Gate Drivers:

Gate drivers connect the controller to the power stage. They boost the controller’s weak signals to control MOSFETs or IGBTs. Half-bridge gate drivers are helpful because they add deadtime to stop both transistors from working at the same time.

Tip: Pick parts that match your motor’s voltage and current needs for safe use.

Handling Offset Voltage and Deadtime

Offset voltage and deadtime are important for keeping the motor safe and working well.

Offset Voltage:

Offset voltage must be higher than the bus voltage. This ensures the high-side transistors work properly. If it’s too low, the motor may run poorly or get damaged.Deadtime:

Deadtime is a short pause when both transistors in a half-bridge are off. This stops short circuits, called shoot-through. Half-bridge gate drivers often have built-in deadtime. For example, 100 ns deadtime at 20 kHz switching frequency causes a 0.2% power loss. Higher frequencies can increase this loss, so balance safety and efficiency.

Note: Check your gate driver’s deadtime settings to avoid wasting power while staying safe.

PCB Design Tips for Better Performance

A good PCB design keeps the motor stable and reduces noise. Bad layouts can cause problems like electromagnetic interference (EMI). Use these tips to improve your PCB:

Place Components Well:

Put high-current parts, like MOSFETs and gate drivers, close together. Shorter traces lower resistance and improve efficiency.Use a Ground Plane:

A solid ground plane gives return currents a clear path. This lowers noise and makes the circuit more stable.Reduce Noise:

Adjust the DC filter to cut noise at low frequencies. For example, changing PWM frequencies between 18 kHz and 22 kHz spreads energy across more frequencies, reducing peaks.Combine PCB Designs:

If your system uses different voltages, make one PCB with parts for each voltage. This can share up to 90% of the design, saving money and making production easier.

Pro Tip: Add decoupling capacitors near power pins to filter high-frequency noise.

By following these steps, you can design a PCB that improves how your BLDC motor works and lasts.

Firmware Development for BLDC Motor Control

Creating firmware for a brushless DC motor means writing code to control its movement. This includes managing how it spins, its speed, and its strength (torque). The goal is to make the motor work smoothly and reliably. Let’s break down the steps.

Writing Commutation Logic

Commutation logic tells the motor when to power its parts to keep spinning. This can be done using simple boards like Arduino or more advanced processors.

For example, a project called "BLDC Motor Control With Arduino" showed how to use PWM signals and Hall sensors for this. It also included features like braking and alternatives to logic gates. Here’s a quick summary:

Feature | Details |

|---|---|

Project Name | BLDC Motor Control With Arduino |

Focus Area | Commutation logic for motor control |

Tools Used | Arduino, PWM, Hall Sensors |

Special Features | Regenerative braking, L6234 IC |

By following similar steps, you can write code that makes the motor run efficiently.

Implementing Speed and Torque Control Algorithms

Speed and torque control help the motor perform better. You can do this by adjusting how much power goes to the motor and controlling the current. These methods also keep the motor stable and prevent damage.

Here are some ways to do it:

Calculate when to switch power based on the rotor’s position.

Change the PWM duty cycle to adjust the motor’s speed.

Limit the current to control torque and avoid overload.

Use back-EMF sensing to find the rotor’s position without extra sensors.

Switch between control methods depending on the motor’s needs.

The table below shows how these techniques improve motor control:

Technique Description | Purpose |

|---|---|

Calculate timing for commutation based on rotor position. | Ensures smooth and efficient motor operation. |

Adjust PWM duty cycle to motor phases. | Allows precise speed control. |

Limit the current in active motor phases. | Prevents overload and keeps torque steady. |

Use back-EMF sensing in sensorless mode. | Detects rotor position without extra hardware. |

Switch control methods based on operating conditions. | Improves performance under different situations. |

These strategies help you fine-tune the motor for different tasks.

Testing and Debugging the Firmware

Testing and fixing your code is important to make sure it works well. Start with simple checks, like ensuring the board communicates and PWM signals are correct. Use debugging tools to find and fix problems early.

Here are some tips for debugging:

Test basic things first, like blinking an LED to check hardware.

Slowly move to harder tests, like reading inputs or using SPI communication.

Compare results from different tests to spot errors.

Work with others to get new ideas for solving problems.

Keep improving your code by testing and fixing it repeatedly.

Tip: Working with a partner while debugging can help solve problems faster.

By carefully testing and debugging, you can ensure your firmware runs the motor reliably.

Creating a BLDC motor control circuit means learning key steps. These include picking the right parts, handling current and voltage, and writing good code. You also need to know driving methods like trapezoidal and sinusoidal drives. Choose the one that fits your project best. Careful design and coding are needed for smooth and stable performance.

Begin with simple circuits and test them often. Try at least 20 tests to reduce mistakes and improve results. This helps make your design stronger and more reliable. With time and practice, you’ll get better at controlling BLDC motors.

FAQ

1. How can I start learning to control a BLDC motor?

Begin with small projects like using an Arduino to control a BLDC motor. Learn basic ideas like PWM signals and sensing rotor position. Slowly move to advanced methods like Field Oriented Control (FOC).

Tip: Use sensor-based control first. It’s easier to debug than sensorless.

2. Should I use trapezoidal or sinusoidal drives?

Use trapezoidal drives for cheaper systems that don’t need smooth motion. Pick sinusoidal drives for quieter, high-performance tasks like drones or robots.

Drive Type | Best For | Key Benefit |

|---|---|---|

Trapezoidal | Simple tools, vehicles | Lower cost |

Sinusoidal | Robots, medical devices | Smooth operation |

3. Is it possible to control a BLDC motor without sensors?

Yes, you can use sensorless control, which relies on back electromotive force (BEMF) to find rotor position. It’s cheaper and works in tough conditions. But it needs accurate algorithms and is harder to debug.

Note: Sensorless control is best where physical sensors might fail.

4. What tools help debug BLDC motor firmware?

Oscilloscopes check PWM signals and rotor position. Logic analyzers help with communication protocols like SPI. Test simple functions first, then move to harder ones.

Pro Tip: Check hardware connections before fixing software problems.

5. How do I lower noise in a BLDC motor circuit?

Use a solid ground plane and keep high-current parts close together. Change PWM frequencies to spread energy across bands. Add decoupling capacitors near power pins to reduce high-frequency noise.

Emoji Reminder: 🛠️ Good PCB design reduces EMI and makes circuits stable.

See Also

Brushed Versus Brushless 3 Volt Motors: A Comparison

Investing in Mini Brushless Motors for Precision Tasks

Mini Motors Explained: Types, Uses, and How to Choose

Understanding Motor Brushes: Key Parts for Vibration Motor Care

Selecting the Best Configuration for Battery Electric Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry