Controlled Vibration Systems: Engineering Precision for Optimal Performance and User Experience

Controlled vibration systems are important in today's engineering and design. These systems control vibrations carefully to improve how things work. They also make using products more enjoyable for people. For instance, haptic feedback creates touch-like feelings, making digital use more fun. Vibrations in phones let you get alerts without sounds or lights. This makes phones easier to use. Many industries now focus on controlling vibrations to make better and more comfortable products. It also helps meet rules and standards. INEED designs vibration motors that work well for many uses.

Key Takeaways

Controlled vibration systems help machines work better and feel smoother.

INEED's vibration motors make devices more accurate and fun to use.

Checking vibrations often stops machines from breaking, saving money and time.

Controlled vibrations in cars give smoother rides and happier passengers.

Custom vibration motors fit special needs, making devices work even better.

Understanding Controlled Vibration Systems

What Are Controlled Vibration Systems?

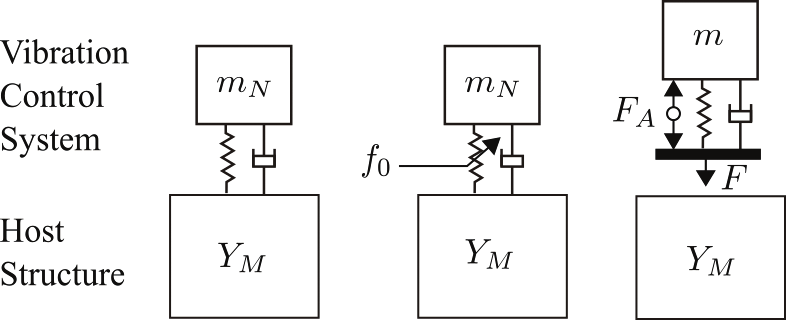

Controlled vibration systems are setups made to manage vibrations. They are important in industries where vibrations can cause problems. For example, in airplanes, they reduce engine and turbulence vibrations. This keeps the structure safe and strong. In cars, they make rides smoother by reducing engine and road vibrations. Machines in factories last longer because these systems lower wear and tear. In hospitals, they keep MRI machines steady for clear images.

Think of these systems as tools that keep machines balanced. By controlling vibrations, they help machines work better and last longer. This makes them very useful in modern engineering.

Key Components and Mechanisms of Controlled Vibration Systems

Controlled vibration systems have important parts to work well. One key part is the vibration sensor. It finds and measures vibrations using special tools like MEMS accelerometers. These sensors collect data about how strong and fast vibrations are. Engineers use this data to fix problems and improve machines.

Another part is the vibration isolation system. These systems, like air-filled isolators, block outside vibrations. They keep sensitive machines steady even in shaky places. Advanced vibration meters are also important. They measure how fast and far things move, giving engineers helpful details.

These systems also use spectral analysis. This method shows how strong vibrations are at different speeds. It helps find natural frequencies, which can cause problems if not controlled.

By using these parts and methods, controlled vibration systems work accurately. They make machines safer, more efficient, and better for users in many fields.

Engineering Precision with Controlled Vibration Systems

The Role of Precision in Engineering Applications

Precision is very important in engineering. It helps systems work well, stay safe, and last longer. If vibrations are not controlled, they can harm structures, lower performance, or cause safety problems. Controlled vibration systems solve these issues by managing vibrations carefully. This makes them essential for many important tasks.

Structural integrity monitoring: Engineers check vibration data during building projects. This shows how strong structures are over time. It helps find weak spots and keeps them safe for years.

Machinery maintenance: Watching vibrations all the time helps spot problems early. This stops big repairs and makes machines last longer.

Ground vibration control: In building work, sensors reduce vibrations to protect nearby buildings. This also makes the area safer.

Worker safety: Vibration data helps plan better and lower risks. This creates safer places for workers.

In factories and other industries, precision engineering has made big improvements. For example, using ultrasonic vibration in milling has cut the force needed by 50%. It also makes smoother surfaces and fewer mistakes compared to regular milling. These examples show how controlled vibration systems improve precision. They help machines work better and make higher-quality products.

How INEED's Vibration Motors Enhance Precision

INEED's vibration motors are made to give top-level precision. They control vibrations well, making devices work better and more reliably. Whether used in big machines or small gadgets, these motors bring the balance and accuracy needed for great results.

Metric/Factor | Description |

|---|---|

Load Distribution | Special gear systems share the load evenly. This lowers vibrations and keeps things steady. |

Fixed Carrier Setup | This setup reduces vibrations, perfect for big machines needing steady power. |

Gear Alignment | Good alignment cuts noise and keeps systems stable, which is key for precision. |

Material Properties | Materials that absorb vibrations make systems more stable overall. |

Configuration-Specific Impacts | Different setups, like fixed sun or ring, change how vibrations are controlled. |

INEED's motors can also be customized for different needs. For example, their Linear Resonant Actuators (LRAs) give steady vibrations and great touch feedback. This makes them perfect for wearables and phones. Adding these motors to your systems boosts precision, improves performance, and makes users happier.

Optimizing Performance Through Controlled Vibration

Performance Benefits in Industrial and Consumer Applications

Using controlled vibration systems can greatly improve how things work. These systems lower unwanted vibrations, helping machines run smoothly and last longer. They also make devices easier and more fun to use for people.

In factories, these systems are very important for safety and efficiency. Here are some main benefits:

Better Maintenance: Vibration checks find problems early by comparing patterns. This saves time and money on repairs.

Improved Vibration Control: Sensors measure vibrations and adjust them instantly for stability.

Growing Market: The vibration control market is expected to grow a lot soon. Passive systems soak up vibrations, while hybrid ones mix passive and powered parts for better results.

For everyday devices, these systems make them work better. For example, phones use vibration motors for alerts and typing feedback. Wearables give quiet notifications and track health without interrupting your day.

Adding controlled vibration systems helps machines work better and makes products easier to use.

Real-World Examples of INEED's Vibration Motor Applications

INEED's vibration motors are useful in many industries. They are made to give accurate vibrations, improving how devices work and feel.

Application Type | Description |

|---|---|

Smartphones | Vibrations for alerts and typing feedback |

Wearables | Quiet alerts and health tracking |

These motors are also used in smart cars and robots. In cars, they give vibration alerts to keep drivers safe. In robots, they provide touch feedback, making them easier to use in homes and hospitals.

These examples show how flexible INEED's motors are. Whether in gadgets or big machines, they improve performance and make users happy.

Enhancing User Experience with Controlled Vibration Systems

The Impact of Vibration Control on User Comfort and Safety

Controlling vibrations helps make things safer and more comfortable. If vibrations are not managed, they can cause discomfort or tiredness. In vehicles, road and engine vibrations can bother passengers. Reducing these vibrations makes rides smoother and more enjoyable. Studies show that both vibration levels and passenger opinions matter. A driving simulator study found that fewer vibrations make passengers feel better during trips.

Rules like ISO-2631 explain how vibrations affect people’s bodies. These rules show which vibration levels can cause motion sickness. Engineers use this information to design systems that improve comfort and lower health risks. For example, controlling vibrations in cars makes rides safer by reducing distractions. Whether you’re in a car, train, or plane, controlled vibrations make travel better and safer.

How INEED's Vibration Motors Improve User Interaction

INEED's vibration motors make using devices easier and more fun. These motors create steady vibrations that feel smooth and natural. For example, when typing on a phone, the small vibrations you feel come from these motors. They make notifications and typing more enjoyable.

In fitness trackers, these motors give quiet alerts without bothering others. This helps you stay connected while keeping things private. INEED's Linear Resonant Actuators (LRAs) are great for creating realistic vibrations. They work well in gaming controllers and medical tools. Adding these motors to products makes them more interactive and satisfying to use.

Innovations in Controlled Vibration Systems

Emerging Technologies in Vibration Control

Vibration control is improving fast with smarter systems. These systems can now adjust vibrations instantly, making machines safer. For example, online tools let engineers watch machine vibrations all the time. This helps find problems early and avoids long repairs. Active systems that cancel noise and vibrations are also popular. They use sensors and tools to stop unwanted movements, helping industries like healthcare and aerospace.

New materials are also making a big difference. Scientists have created special plastics that soak up vibrations well. These materials are strong and reduce shaking, perfect for cars and buses. Imagine a car ride where you barely feel the bumps. This is possible because of these new materials. Another cool idea is granular damping, which cuts engine and road vibrations for a smoother ride.

Experts like Elias Brassitos are leading the way in vibration control. His work in space robots has created new designs and patents. These ideas improve accuracy and work even in tough places. As these technologies grow, they will make machines quieter, safer, and more dependable.

Future Directions for INEED's Vibration Motor Solutions

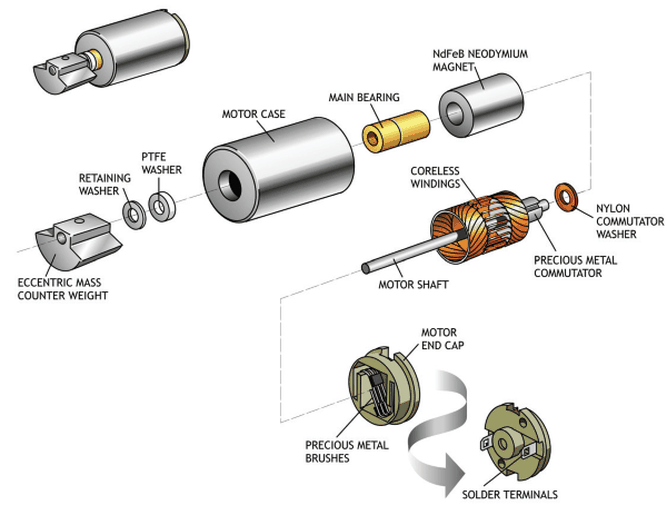

INEED is ready to lead the future of vibration motors. Eccentric Rotating Mass (ERM) motors are becoming more popular in gadgets like phones and watches. These motors will soon be even better and more useful. In Asia-Pacific, more people are buying smartphones, giving INEED a chance to grow. By making custom motors, INEED can meet the needs of this market.

Cars also offer exciting chances for vibration motors. Systems like driver alerts and entertainment screens need precise vibrations to work well. INEED's motors can make driving safer and more fun. Electric cars are another area where these motors can help. They can give feedback for alerts, making driving easier and better.

As technology improves, INEED plans to stay ahead by creating smarter designs. Whether through new materials or better ideas, INEED’s motors will keep setting high standards. By following these trends, your devices can have the best vibration solutions available.

Controlled vibration systems are important for better machines and user comfort. They help machines work well, last longer, and feel safer. For example, G3 vibrations reached 97% accuracy, showing great results. People also liked using the system, proving it keeps users happy.

INEED is a leader in making advanced vibration motors. Their custom solutions, like Linear Resonant Actuators, give steady and accurate vibrations. These motors work well for many uses. Check out INEED's motors to improve your devices and fit your needs.

FAQ

Why are controlled vibration systems important in modern industries?

Controlled vibration systems make machines safer and work better. They help stop damage to machines, make users more comfortable, and ensure accurate performance in delicate areas like medical tools and space technology.

Why should you choose INEED's vibration motors?

INEED's vibration motors are precise, strong, and customizable. They work well in many devices, from phones to factory machines. Their smart designs use less power and work dependably, saving money over time.

Tip: Check out INEED's custom options to find the right motor for you.

Why do vibration motors enhance user experience?

Vibration motors give touch feedback, making devices easier to use. For example, they improve typing on phones and give quiet alerts on fitness bands. This makes devices more fun and useful.

Why is customization crucial for vibration motors?

Customization makes sure the motor fits your needs perfectly. INEED offers options like changing vibration strength, speed, and size. This makes sure the motor works its best and keeps users happy.

Why is INEED a trusted name in vibration motor technology?

INEED has been making small motors for over 10 years. They focus on quality, new ideas, and happy customers. This makes them a trusted choice in fields like healthcare, robots, and phones.

Note: Visit INEED's website to learn more about their advanced motors.

See Also

10 Innovative Methods Micro Vibration Technology Improves Precision Tools

Your Comprehensive Guide to Top Vibration Measurement Tools

Revolutionary Advances in Vibration Tech Transforming Haptic Feedback

The Advantages of Linear Vibration Motors for Haptic Feedback

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry