How to Control Resonance Frequency in Vibration Motors for Reliable Operation

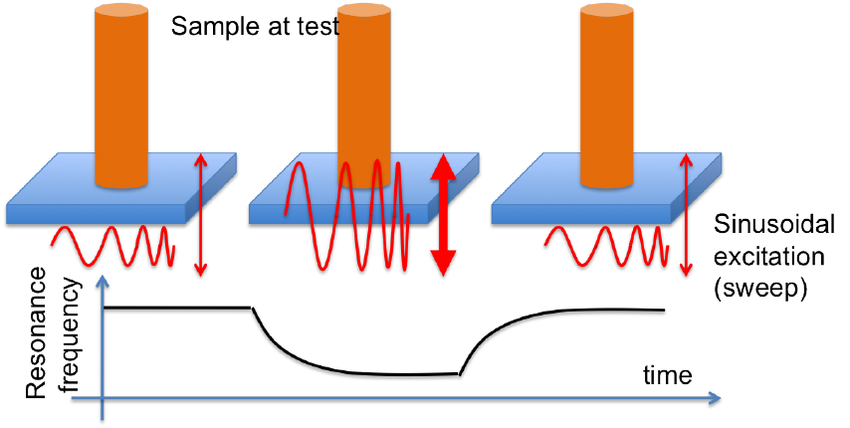

Controlling how vibration motors resonate keeps them working well and efficient. If a motor runs at its resonance frequency, it shakes too much. This can break parts and waste energy. For example, the first resonance happens at 8,789 Hz, and the second at 19,531 Hz. Running the motor outside these numbers keeps it steady and working properly.

More people want better ways to control vibrations. The market for linear vibration motors might grow to $3,511.64 million by 2031. This shows how important it is to manage resonance carefully.

INEED's vibration motors solve these problems with smart designs and custom options. They focus on being strong and accurate. This helps them work better and avoid problems caused by resonance.

Key Takeaways

Knowing resonance frequency is important for vibration motors. It boosts performance and avoids damage.

Checking and fixing motors often can find problems early. This saves money and makes motors last longer.

Adjusting parts can help control resonance. Use tougher materials and better designs to lower vibrations.

Tools like accelerometers and trackers can find resonance easily. These tools give useful data to manage motors well.

Picking good motors, like INEED ones, makes them strong and efficient. Custom choices and expert help control resonance better.

Understanding Resonance Frequency in Vibration Motors

What is Resonance Frequency?

Resonance frequency is the point where vibrations are strongest. It happens when a system's natural rhythm matches an outside force. For vibration motors, this means the motor vibrates more when its natural frequency aligns with the force applied. At this point, the motor uses energy well, but vibrations increase.

Think of it like pushing a swing. If you push at the right time, the swing goes higher. Similarly, when a motor hits its resonance frequency, vibrations grow stronger. This can improve performance but may also cause damage or wear.

Engineers find resonance by testing when vibrations are strongest.

Small forces near this frequency can make big vibrations, storing energy.

Why Resonance Frequency Matters in Vibration Motors

Knowing and controlling resonance frequency keeps vibration motors working well. When a motor runs near its resonance, vibrations get bigger. This can lead to:

Better Performance: In some cases, like speakers, resonance boosts output with less energy. For example, sound graphs show how resonance improves audio systems.

Possible Damage: Too much vibration can harm parts, causing wear or failure. Engineers study resonance to see how it affects motor strength and stability.

Improved Design: Finding resonance helps makers adjust designs to lower unwanted vibrations. This keeps motors safe and efficient.

A motor's reliability depends on managing its resonance frequency. Fixing resonance early avoids problems and helps the motor last longer.

📊 Did You Know? Charts show how damping lowers resonance peaks. More damping makes motors steadier and safer to use.

Common Causes of Resonance Issues in Vibration Motors

Mechanical Factors Affecting Resonance

Mechanical resonance happens when outside forces make vibrations stronger. This occurs at the motor's natural frequency and can cause damage. Things like the motor's base, load weight, and part flexibility affect this. For example, a soft motor base can increase vibrations, making the motor shake more.

To fix this, you can make the system stiffer. Use stronger parts or change the load-to-motor weight balance. Adjusting the motor base also helps reduce shaking. These fixes keep the motor running smoothly and prevent damage.

📋 Quick Reference Table:

Cause of Resonance | Description | Solutions |

|---|---|---|

Mechanical Resonance | Happens when outside forces boost vibration at natural frequency. | Use stronger parts, adjust load-to-motor weight, or change motor base. |

Electrical Factors Influencing Resonance

Electrical issues like harmonics and winding setups affect resonance. Harmonics can make vibrations worse and overheat the motor. Bad winding designs can increase these problems, but good winding setups reduce harmful harmonics.

You can avoid electrical resonance by programming the Variable Frequency Drive (VFD) to skip problem frequencies. Changing motor designs, like winding setups, also helps. These steps improve motor life and stop damage from high voltage or current.

Environmental Impacts on Resonance Frequency

Outside conditions like heat, moisture, and nearby vibrations can change the motor's resonance frequency. For instance, high heat can change materials, affecting how the motor vibrates. Vibrations from other machines can also disturb the motor's natural frequency.

To reduce these effects, use good insulation and vibration isolation. Materials that resist heat and moisture help keep the motor stable. These steps ensure the motor works well in different environments.

How to Control Resonance Frequency in Vibration Motors

Mechanical Adjustments for Optimizing Resonance

You can change the motor's setup to lower resonance effects. Check the motor's base and structure first. A weak base makes vibrations worse and less stable. Use stronger materials or adjust the weight to fix this. Changing the center of gravity or stiffening the mount helps reduce shaking.

Another way is to balance the load and motor size. A heavy load compared to the motor causes more shaking. Use a bigger motor or lighten the load to fix this. These changes make the motor run smoother and last longer.

💡 Tip: Add vibration pads or mounts to absorb extra shaking. These pads block outside forces from making vibrations worse.

Electrical Solutions for Controlling Resonance

Electrical fixes are key to managing resonance. Power supply problems can increase vibrations and heat. To stop this, program the Variable Frequency Drive (VFD) to skip bad frequencies. This keeps the motor from running at its resonant frequency.

Better winding designs also help. Bad windings make vibrations worse, but good ones reduce them. Filters in the power system block unwanted frequencies, protecting the motor from harm.

⚙️ Pro Tip: Check the motor's wires and power often. Loose wires or power changes can make resonance worse, so keep them steady.

Tuning Techniques for Precise Resonance Management

Fine-tuning the motor helps control resonance better. First, find the motor's resonant frequency using tools like accelerometers. Once you know it, adjust the motor's speed to avoid that frequency.

You can also use damping materials to absorb vibrations. For example, damping tape or coatings on the motor reduce shaking. This makes the motor more stable.

Dynamic balancing is another option. It fixes uneven weight in the motor's moving parts. A balanced motor shakes less and avoids hitting its resonant frequency.

📊 Did You Know? Balancing the motor not only reduces shaking but also helps it last longer by avoiding damage.

Tools for Measuring and Analyzing Resonance Frequency

Using Accelerometers for Resonance Detection

Accelerometers help find resonance in vibration motors. These sensors turn movement into electrical signals. They show the motor's natural frequency and how it behaves in different situations. Mounting them correctly gives accurate results. If placed wrong, the data may be unreliable.

To work well, accelerometers need regular calibration. Calibration links vibrations to the sensor's readings. Without it, errors can happen, making measurements unclear. Also, accelerometers have different sensitivity levels. Pick one that matches your motor's frequency range.

🔍 Tip: Choose accelerometers with wide frequency ranges for better accuracy.

Noise in the sensor's output can lower precision. Filters can remove unwanted noise from the data. This helps focus on the important vibration signals for analysis.

Order Tracking Analysis for Frequency Optimization

Order tracking helps improve vibration motor performance. It breaks down vibration signals into parts based on rotation. This makes it easier to find problems in the motor.

For example, order tracking shows which frequencies come from specific motor parts. This helps fix issues and adjust settings for better operation. If the motor's speed changes, order tracking still works well. It handles vibrations even when speeds vary.

📈 Pro Tip: Use order tracking with envelope analysis for better fault detection.

Order tracking also shows harmonic patterns in the frequency spectrum. These patterns explain how motor parts interact. Fixing these issues early makes the motor last longer and lowers repair costs.

Waterfall Plots for Visualizing Resonance Behavior

Waterfall plots show how resonance changes over time. These 3D graphs display vibration frequency, motor speed, and amplitude. They help track how vibrations shift during operation.

One use of waterfall plots is checking machine health. For example, they show how worn bearings affect vibration. Sudden spikes may mean damage or failure. In pumps, waterfall plots show how vibrations change with motor speed. This helps avoid resonance by adjusting speed.

📊 Did You Know? Waterfall plots are great for spotting sudden impacts or failures.

Waterfall plots give a clear view of motor behavior. They help decide when to fix or adjust the motor. This keeps the motor safe and prevents damage.

Best Practices for Reliable Operation of Vibration Motors

Regular Monitoring and Maintenance

Check vibration motors often to keep them safe and efficient. Watching vibration patterns helps find problems like loose bolts or worn bearings early. Fixing these issues quickly avoids expensive repairs and breakdowns.

Tools like vibration analysis show hidden problems and alignment issues. Real-time monitoring warns you about risks, improving safety. Keeping maintenance records helps track motor health and plan fixes on time.

📋 Key Metrics for Monitoring:

Mean Time Between Failure (MTBF): Tracks how long a motor works before failing.

Vibration Analysis: Finds alignment problems and mechanical stress.

Condition Monitoring: Spots defects early to prevent downtime.

Proactive Adjustments for Long-Term Efficiency

Fixing small problems early keeps motors working longer. Watching motor performance lets you plan repairs during downtime, avoiding interruptions. Balancing the motor's load or adjusting its speed reduces wear and saves energy.

Predictive maintenance stops surprise breakdowns and improves efficiency. Using damping pads or isolation materials lowers extra vibrations. These simple fixes protect the motor and make it last longer.

💡 Tip: Add vibration pads to block outside forces. This helps the motor work better and stay safe.

Leveraging INEED's Expertise in Vibration Motor Solutions

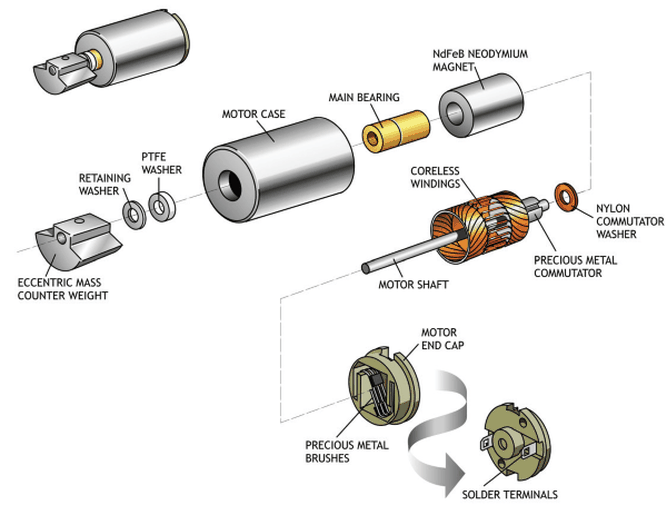

INEED makes motors that are strong and precise. Their motors, like Linear Resonant Actuators (LRAs) and coreless DC motors, reduce unwanted vibrations. These motors are built to last and work reliably.

INEED offers custom options like connectors and mounts for easy setup. Their expert support helps you manage resonance and improve motor performance. Choosing INEED gives you trusted solutions for industries like healthcare and robotics.

🌟 Why Choose INEED?

Durable motors with custom features.

Expert help for managing resonance and boosting efficiency.

Reliable products for healthcare, robotics, and wearable devices.

Finding and managing resonance frequency helps vibration motors work well. Controlling resonance stops damage, saves energy, and makes motors last longer. Checking motors often and fixing small problems early keeps them running smoothly.

📊 Key Insights:

Aspect

Description

Resonance Identification

Finds natural vibrations and frequencies in machines.

Impact of Resonance

High vibrations from resonance can harm the motor.

INEED's vibration motors are made to fit your needs. Their smart designs help reduce resonance problems. Try their products to make your motor stronger and more reliable.

FAQ

How can you measure resonance frequency in vibration motors?

Use tools like accelerometers to measure vibrations. These tools find the motor's natural frequency by turning vibrations into signals. Place the sensor correctly for accurate results. Calibrating the accelerometer often makes the data more reliable.

What does resonance frequency do to an electric motor?

Resonance frequency makes an electric motor vibrate more. This can cause parts to wear out, lower efficiency, or even break. Avoid running the motor near this frequency to keep it working well and lasting longer.

Can the environment change a motor's resonance frequency?

Yes, things like heat, moisture, and outside vibrations can change it. For example, heat can affect materials and how they vibrate. Using materials that resist heat and isolating vibrations helps the motor stay steady.

How do you study vibration data to make motors better?

You can use tools like order tracking and waterfall plots. These tools break down vibration data to find problems like misalignment or wear. Fixing these issues makes the motor work better and last longer.

Why is tuning important for controlling resonance frequency?

Tuning changes the motor's speed or adds damping to avoid resonance. This lowers harmful vibrations and keeps the motor stable. Using balancing and damping materials helps control vibrations more precisely.

See Also

Exploring Resonant Systems: Impact on Vibration Motor Efficiency

Choosing the Perfect Vibrating Motor for Your Needs

Maintaining Electric Vibration Motors for Longevity and Efficiency

Effective Strategies for Diagnosing and Fixing Motor Vibrations

Understanding Vibration Motors in Haptic Feedback Technology

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry