Compatibility Challenges between DC Motors and AC Power Systems and their Integration Solutions

DC motors and AC power systems work in different ways. This difference creates major compatibility challenges. Many people use dc motors in systems for smart homes, factories, or green energy. They often face problems because dc and ac use different types of electricity. Safety and efficiency become big concerns. If someone does not understand the compatibility between a dc motor and an ac system, they could damage the motor or the whole system. People need to know why these issues happen before they try any integration.

Key Takeaways

DC motors and AC power systems use different types of electricity, which creates challenges in connecting them safely and efficiently.

Special devices like rectifiers, inverters, and converters are essential to convert power between AC and DC, ensuring motors work properly and last longer.

Proper control systems, such as Variable Frequency Drives and smart electronics, help manage motor speed, reduce energy waste, and prevent damage.

Good installation and maintenance practices, including secure mounting, correct wiring, and cooling, improve motor performance and prevent failures.

Hybrid AC/DC systems combine the strengths of both motor types, boosting energy efficiency and supporting renewable energy use in homes and industries.

Compatibility Challenges

Electrical Differences

DC motors and AC motors use different types of electricity. DC motors need direct current, while AC motors run on alternating current. This difference creates major compatibility challenges when connecting DC motors to AC power systems. AC voltage can be changed easily with transformers. These devices step voltage up or down for safe and efficient transmission. DC voltage does not work with simple transformers. Instead, engineers must use complex and expensive power electronic converters. These converters add cost and make the system harder to design. In the past, AC became popular because transformers made voltage changes simple and cheap. Today, connecting DC motors to AC systems still needs special electronics like inverters and converters. These devices change AC to DC or DC to AC, but they increase system complexity and cost. Many renewable energy systems, such as solar panels, produce DC. To use this energy with AC power systems, inverters must convert the electricity. This process shows why voltage conversion remains a big challenge for compatibility.

Operational Issues

When engineers try to use DC motors with AC power systems, they face many operational problems. Vibrations and noise often increase during integration. Variable Frequency Drives (VFDs) control motor speed by changing the frequency of the AC supply. These drives can cause harmonic currents, which lead to extra noise and vibration. At lower speeds, motors may run quieter, but they can vibrate more at certain frequencies. Engineers must program VFDs to avoid these problem speeds. The switching frequency of the inverter also affects noise. Higher switching frequencies can make the motor quieter, but they may also cause more heat and reduce efficiency.

Cause Category | Specific Causes | Recommended Actions |

|---|---|---|

Weak bases, loose anchor bolts | Check and tighten all bolts, inspect base condition | |

Electrical Issues | Voltage imbalance, harmonics, insulation faults | Analyze power quality, test connections |

Resonance Issues | Operation near natural frequencies, speed changes | Calculate critical speeds, adjust operation settings |

Other sources of vibration in AC motors include shaft misalignment, bearing defects, and loose connections. Engineers use sensors and data systems to measure and analyze these vibrations. Standards like ISO 10816-3 and NEMA set safe vibration limits. Following these standards helps protect the motor and maintain efficiency. These operational issues show why careful control and monitoring are needed when integrating DC motors with AC power systems.

Safety and Efficiency

Safety risks and efficiency losses are major concerns in hybrid systems that use both DC motors and AC power. Heat dissipation is a big problem. When motors run too hot, their materials can lose strength, causing permanent damage. Engineers use cooling methods like air, liquid, or phase change materials to manage heat. Liquid cooling works well for high heat, while phase change materials absorb extra heat and keep temperatures steady. Some companies use advanced cooling systems, such as micro-channel heat sinks and vapor chambers, to improve safety and efficiency.

Aspect | Description | Examples |

|---|---|---|

Thermal Management Challenges | Hotspots, limited cooling space, variable temperatures, overheating risks | Tesla's thermal system, BMW's phase change materials, Audi's waste heat recovery |

Cooling Technologies | Advanced materials, liquid cooling, phase change, smart sensors | Immersion cooling, smart temperature control |

EMC Challenges | High electronic density, EMI, safety system interference, switching noise | Airbag deployment issues, EMC design in electric vehicles |

Lessons Learned | Better cooling and EMC design improve efficiency and safety | Industry-wide adoption of integrated management strategies |

Electromagnetic compatibility also matters. High-frequency switching in power electronics can cause interference and safety problems. Engineers must design systems to avoid these risks. Good thermal management and electromagnetic compatibility help improve long-term operational efficiency and motor efficiency. These solutions also support higher efficiency rates and lower energy consumption. By understanding these safety and efficiency challenges, engineers can build systems that use less energy and last longer.

Integration Solutions

Power Conversion

Why do engineers need special devices to connect dc motors to ac power? The answer lies in the fundamental difference between dc and ac electricity. Dc motors require a steady flow of direct current, but most buildings and factories supply alternating current. This mismatch creates a need for power conversion.

Rectifiers, inverters, and converters play a key role in this process. Rectifiers change ac into dc, making it possible for dc motors to run on standard ac power. Inverters can also convert dc back into ac when needed. Modern converters use advanced semiconductor switches like IGBTs and MOSFETs. These switches allow high-frequency operation and precise waveform control. Engineers prefer pure sine wave output for sensitive electronics because it prevents device issues.

Aspect | Details |

|---|---|

Semiconductor switches | Use of IGBTs and MOSFETs for high-frequency switching and precise waveform control |

Efficiency benchmarks | MPPT technology achieves 98-100% efficiency; microinverters provide 5-10% efficiency gains over traditional inverters |

Harmonic distortion | Modern inverter designs reduce total harmonic distortion (THD) from ~25% to 0.05% |

Power ratings | Up to 130 kW for small vehicles, 130-250 kW for medium vehicles, above 250 kW for heavy-duty vehicles |

Waveform quality | Pure sine wave output preferred for sensitive electronics |

Control strategies | Advanced algorithms for switching signals, MPPT, and bidirectional power flow |

Why do these devices matter? They ensure compatibility, reliability, and optimal performance for dc motors in ac systems. Adaptive frequency conversion and soft-switching techniques further improve efficiency. These methods reduce losses and heat, which helps maintain long-term operational efficiency. Engineers also use filters and regulators to smooth the dc output and keep voltage stable. These steps support precise power delivery and protect both the motor and the system.

Many industries rely on these power conversion techniques. Automotive, renewable energy, and uninterruptible power supplies all use converters to run dc motors from ac sources. The widespread use of these devices shows their effectiveness in solving compatibility challenges.

Tip: Always select converters with the right power rating and waveform quality for your application. This choice prevents damage and improves efficiency.

Control Systems

Why do dc motors need advanced control systems when integrated with ac power? The answer comes from the need for stable operation and precise performance. Dc motors respond quickly to changes in voltage and current. Without proper control, they can overheat or run at unsafe speeds.

Automation interfaces and control electronics help manage these risks. Variable Frequency Drives (VFDs) allow engineers to adjust motor speed and torque by changing the frequency and voltage of the ac supply. This flexibility improves efficiency and reduces energy waste. Brushless dc motors use electronic commutation, which removes the need for brushes and lowers mechanical wear. Smart electronics enable real-time adjustments, so the motor can adapt to changing loads.

AC/DC converters transform ac voltage into dc voltage for dc motor operation.

Key components include transformers, rectifiers, filters, and regulators.

These converters support battery charging and stable power supply.

VFDs enable precise control of motor speed and torque.

Brushless dc motors increase efficiency and reliability.

Smart electronics improve performance under varying load conditions.

Feedback control systems and electromagnetic shielding reduce torque fluctuations and interference.

Why do these control systems matter? They help dc motors work smoothly with ac power, even in complex environments. Scientific studies and industry experience show that these systems save energy and improve reliability. For example, VFDs have reduced energy use by up to 40% in HVAC and 25% in manufacturing. Solar trackers with brushless dc motors capture 30% more energy, and robotics achieve faster assembly speeds.

Recent technical analyses also show that AI-based methods can predict the lifetime of power converters. This prediction helps engineers plan maintenance and avoid unexpected failures. These advances make control systems more reliable and support the safe integration of dc motors into ac systems.

Note: Regularly monitor control electronics for signs of overheating or abnormal operation. Early detection prevents costly downtime.

Installation Best Practices

Why do installation practices matter for dc motors in ac power systems? Proper installation ensures safety, efficiency, and long equipment life. Mistakes during setup can lead to overheating, vibration, or even system failure.

Engineers follow several best practices:

Check Compatibility: Always verify that the dc motor and converter match the ac supply voltage and frequency.

Secure Mounting: Install motors on solid bases to reduce vibration and noise.

Proper Wiring: Use correct wire sizes and secure all connections to prevent voltage drops and overheating.

Cooling Systems: Install adequate cooling, such as fans or liquid cooling, to manage heat.

Shielding: Use electromagnetic shielding to protect sensitive electronics from interference.

Routine Maintenance: Inspect motors and converters regularly for wear, dust, or loose parts.

Troubleshooting: Use sensors and monitoring tools to detect problems early, such as abnormal vibrations or temperature spikes.

Why do these steps matter? They prevent common issues like heat buildup, electrical faults, and mechanical wear. Good installation and maintenance practices support long-term operational efficiency and reduce the risk of unexpected breakdowns.

Reminder: Keep a maintenance log for each motor and system. This record helps track performance and plan future upgrades.

DC Motors vs AC Motors

Performance Comparison

Why do engineers and designers compare dc motors and ac motors before choosing one for their systems? The answer lies in how each motor performs under different conditions. Dc motors deliver high starting torque because of their direct current operation. This feature makes them strong at the start and allows for quick acceleration. The torque formula for dc motors, T = kt * Ia * φ, shows that torque depends on the armature current and magnetic flux. This gives dc motors an advantage in applications that need strong initial force.

Ac motors, on the other hand, use alternating current. Their speed depends on the supply frequency and the number of poles, as shown by the formula N = 120f / P. Engineers use variable frequency drives to control ac motor speed, but this method can lead to efficiency losses at certain loads. Dc motors maintain higher efficiency at variable speeds, while ac motors reach their best efficiency during continuous operation.

Motor Type | Efficiency Range (%) | Notes on Operational Efficiency and Power Consumption |

|---|---|---|

Brushed DC Motors | 75 - 80 | Lowest efficiency due to brush losses |

Brushless DC Motors | 85 - 90 | Higher efficiency, less slip, fewer moving parts |

AC Induction Motors | 90 - 93 | High efficiency, but slip causes some losses |

Synchronous Motors | Up to 99 | Superior torque, high power density |

Why does this comparison matter? It helps users select the right motor for their needs. Dc motors offer better control and efficiency at different speeds. Ac motors provide robust performance and long life in steady, continuous-duty applications.

Application Suitability

Why do certain applications favor dc motors while others rely on ac motors? The answer comes from the unique strengths of each type. Dc motors excel in applications that require frequent starts, stops, and reversals. Their high starting torque and precise speed control make them ideal for electric vehicles, cranes, and conveyor belts. Engineers choose dc motors for variable speed applications because they can adjust voltage and current easily.

Ac motors, especially induction types, work best in systems that run for long periods without many changes in speed or direction. These motors power industrial machines, HVAC systems, and pumps. Their simple design and high efficiency make them reliable for continuous use.

Dc motors provide fast response times and quick acceleration. This feature benefits robotics and dynamic systems.

Brushless dc motors reduce maintenance needs and increase durability. They suit battery-powered devices like drones and portable tools.

Ac motors handle varying load conditions well. They support heavy-duty industrial applications with fewer breakdowns.

Why do engineers now use dc motors in areas once dominated by ac motors? Advances in brushless dc technology have improved efficiency and reliability. This progress allows dc motors to replace ac motors in many modern applications, especially where precise control and energy savings matter most.

Tip: Always match the motor type to the application's needs. Consider torque, speed control, efficiency, and maintenance when making a choice.

Renewable and Hybrid Systems

Hybrid AC/DC Integration

Why do engineers choose hybrid AC/DC integration for modern energy systems? Hybrid systems combine both ac and dc circuits to support a wide range of applications. Many renewable energy sources, such as solar panels, produce dc electricity. However, most homes and industries use ac motors and ac power. This difference creates a challenge. Engineers use hybrid systems to connect dc motors and ac motors together, allowing each motor to work where it performs best.

Hybrid AC/DC networks help manage the mix of renewable energy sources and traditional power. For example, data centers now use advanced ac-dc power supplies to handle variable energy from renewables. These supplies keep the system reliable and efficient. The HYNET project shows how hybrid networks support dc-based distributed energy resources like solar, batteries, and electric vehicles. These resources often use dc motors for better efficiency and control.

Hybrid systems use tools for reliability, resilience, and smart control. Engineers model both ac and dc parts to keep the system stable. They use grid-forming and inertia support to handle changes in energy supply. HVDC technology reduces transmission losses and connects remote renewable sources to cities. Flexible AC Transmission Systems (FACTS) improve efficiency and support more renewable energy.

Hybrid integration allows dc motors and ac motors to work together, making energy systems more flexible and reliable.

Role in Renewable Energy

Why do renewable energy systems use dc motors more often today? Renewable energy sources like solar and wind often produce dc power. Dc motors connect directly to this power, reducing conversion losses. Studies show that brushless dc motors use less energy than ac motors, which helps lower costs and extends the life of appliances.

Hybrid ac/dc home systems use separate bus bars for ac and dc. This design lets engineers connect each motor to the best power source. For example, dc motors can run directly from solar panels, while ac motors use grid power. This setup avoids the 5% energy loss seen in ac-dc conversions for lighting and other devices.

Hybrid systems also improve environmental advantages. They reduce carbon emissions and fuel use by making better use of renewable energy. Control strategies like droop control and model predictive control help share power and keep the system running smoothly. Hardware tests confirm that hybrid ac/dc systems with dc motors improve efficiency and reduce harmonic distortion.

Benefit | Description |

|---|---|

Lower energy use | Dc motors consume less power than ac motors |

Fewer conversion losses | Direct dc connections avoid extra energy loss |

Environmental advantages | Hybrid systems cut emissions and save fuel |

Better power management | Smart controls keep systems stable and efficient |

Why do these changes matter? They help engineers build energy systems that save money, protect the environment, and support more renewable energy sources. Hybrid ac/dc integration and the use of dc motors play a key role in the future of clean energy applications.

Real-World Applications

Industrial Automation

Why do engineers choose dc motors and ac motors for industrial automation? Factories need motors that can handle different tasks, such as moving conveyor belts, operating robotic arms, and running pumps. Dc motors offer precise speed control and high starting torque, which helps machines start quickly and stop safely. Ac motors provide reliable power for continuous operations and can handle heavy loads. Engineers select dc motors when they need fast changes in speed or direction. They use ac motors for steady, long-term work. Both types of motors help reduce energy consumption by matching the motor to the job. This approach improves efficiency and lowers operational costs in industrial applications.

Smart Home Systems

Why do smart home systems benefit from integrating dc motors? Many modern homes use renewable energy sources like solar panels, which generate dc power. Dc motors connect directly to this power, reducing energy losses from conversion. Studies show that switching to dc systems in homes can cut energy consumption by over 25%. Smart home applications, such as automated blinds, fans, and pumps, use dc motors for better control and lower energy use. The ORA-DL framework demonstrates that real-time adaptive control and IoT sensing can improve grid stability by 96.25% and reduce energy wastage by nearly 13%. These improvements make smart homes more efficient and reliable.

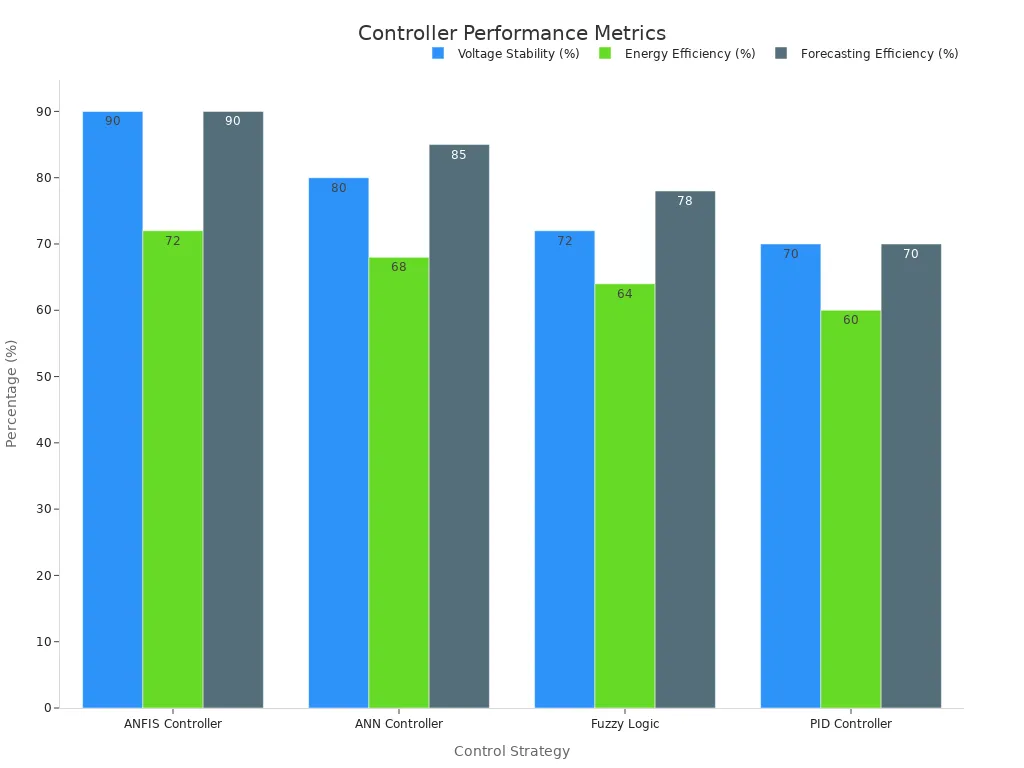

Control Strategy | Voltage Stability (%) | Energy Efficiency (%) | Voltage Variation | Forecasting Efficiency (%) | Key Findings |

|---|---|---|---|---|---|

ANFIS Controller | 90 | 72 | ±2% | 90 | Superior voltage stability and energy efficiency; adapts well to renewable variability; optimal energy management in hybrid microgrids with EV charging and renewable sources. |

ANN Controller | 80 | 68 | ±3% | 85 | Good stability and forecasting; less robust to sudden fluctuations. |

Fuzzy Logic | 72 | 64 | ±4% | 78 | Moderate performance; struggles with unpredictable load changes. |

PID Controller | 70 | 60 | ±5% | 70 | Lowest performance; poor response to load changes and forecasting. |

Why do these results matter? They show that advanced control strategies and dc motors can make smart home applications more stable and efficient, especially when using renewable energy.

Case Studies

Why do real-world case studies highlight the value of integrating dc motors and ac motors in different applications? In manufacturing plants, engineers use dc motors for robotic assembly lines that need quick stops and starts. Ac motors power large fans and compressors that run all day. In smart homes, field data from the ResStock database shows that using dc motors with renewable energy reduces energy consumption and improves system performance. These applications prove that matching the right motor to the right job saves energy and increases efficiency. Engineers continue to study and improve these systems to lower energy consumption and support sustainable living.

Why should engineers focus on careful planning and ongoing maintenance when integrating a motor system? Effective integration of DC motors with AC power systems improves safety and efficiency, as seen in industry reports showing energy savings of 20-30% and reduced downtime. Smart sensors and predictive maintenance help prevent failures and keep each motor running smoothly. Experts recommend combining data-driven methods with real-world knowledge for better results. New hybrid motor systems, like those in aerospace, show why staying updated on technology trends leads to safer and more efficient operations.

FAQ

Why do engineers prefer DC motors in renewable energy systems?

Engineers choose DC motors for renewable energy because solar panels and batteries produce direct current. This match reduces energy loss from conversion. DC motors also offer better efficiency and control in these systems.

Why does integrating DC motors with AC power require special equipment?

DC motors need direct current, but most buildings supply alternating current. Special devices like rectifiers and converters change AC to DC. These devices ensure the motor receives the correct type of electricity.

Why do hybrid AC/DC systems improve energy efficiency?

Hybrid systems let each motor use the best power source. DC motors connect directly to DC power, while AC motors use AC power. This setup reduces conversion losses and saves energy.

Why is safety a concern when combining DC motors and AC systems?

Mixing DC motors with AC systems can cause overheating, electrical faults, or interference. Engineers use cooling systems and shielding to prevent accidents and keep the system safe.

Why do smart homes benefit from DC motor integration?

Smart homes often use solar panels, which generate DC power. DC motors connect directly to this power. This connection lowers energy use and improves control for devices like fans and blinds.

See Also

Typical Issues Faced By 3 Volt Motors And Fixes

How To Choose Mini DC Motors For Industrial Use

Five Ways To Utilize 3 Volt DC Motors Effectively

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry