Comparing Linear Resonant Actuator Types: Which Solution Best Fits Your Product Design?

Choosing the right linear resonant actuator types plays a vital role in achieving optimal product performance. Linear resonant actuators (LRAs) offer several advantages over traditional vibration motors. They provide higher acceleration, crisper haptic feedback, and consume less power during operation. INEED's Linear Vibration Motors deliver innovative solutions tailored to diverse applications, ensuring precision and efficiency. When selecting linear resonant actuator types, you must consider performance metrics, application needs, and design constraints to ensure the best fit for your product.

Key Takeaways

Linear resonant actuators (LRAs) give better vibrations and save energy. They work well in modern gadgets compared to old motors.

Picking the right LRA type—coin, bar, or custom—depends on your product. Think about size, power use, and how strong the vibrations need to be.

Testing with INEED's Linear Vibration Motors can confirm your choice. This helps your device work better and improves user experience.

Understanding Linear Resonant Actuators

What Are Linear Resonant Actuators?

Linear resonant actuators are precision devices designed to create vibrations along a single axis. Unlike traditional motors, they use a voice coil and spring mechanism to generate motion. This design allows them to operate at a specific resonant frequency, typically between 170 to 180 Hz, ensuring efficient performance. Their ability to deliver crisper and more directed haptic feedback makes them ideal for applications requiring precision, such as wearable devices and smartphones.

Attribute | Linear Resonant Actuators (LRAs) | Eccentric Rotating Mass (ERM) | Piezoelectric Actuators |

|---|---|---|---|

Motion Type | Linear | Rotational | Linear |

Narrow | Wide | Variable | |

Power Consumption | Low (typically 2V) | Higher | Variable |

Haptic Feedback Quality | Crisper and more directed | Less precise | High |

Acceleration Capability | Higher than ERM | Lower | Variable |

How LRAs Work in Electric Actuator Technology

Linear resonant actuators operate by moving a mass up and down along a single axis. A magnetic field, generated by a voice coil, interacts with the mass connected to a spring. When an AC voltage is applied, the mass vibrates at the resonant frequency, producing precise haptic feedback. This mechanism allows LRAs to achieve optimal frequency peaks in just 25 milliseconds, making them highly responsive. They also consume less power compared to eccentric rotating mass motors, enhancing their efficiency in electric actuator technology.

Applications of LRAs in Modern Devices

Linear resonant actuators play a crucial role in modern devices. They are widely used in consumer electronics, such as smartphones, where they enhance user interaction through precise haptic feedback. Wearable devices benefit from their compact size and low power consumption. In the automotive sector, LRAs improve tactile feedback in control systems.

One notable example is Apple's Taptic Engine, which integrates LRAs to deliver a seamless and immersive user experience. This demonstrates how LRAs contribute to advancing technology across various industries.

Exploring Linear Resonant Actuator Types

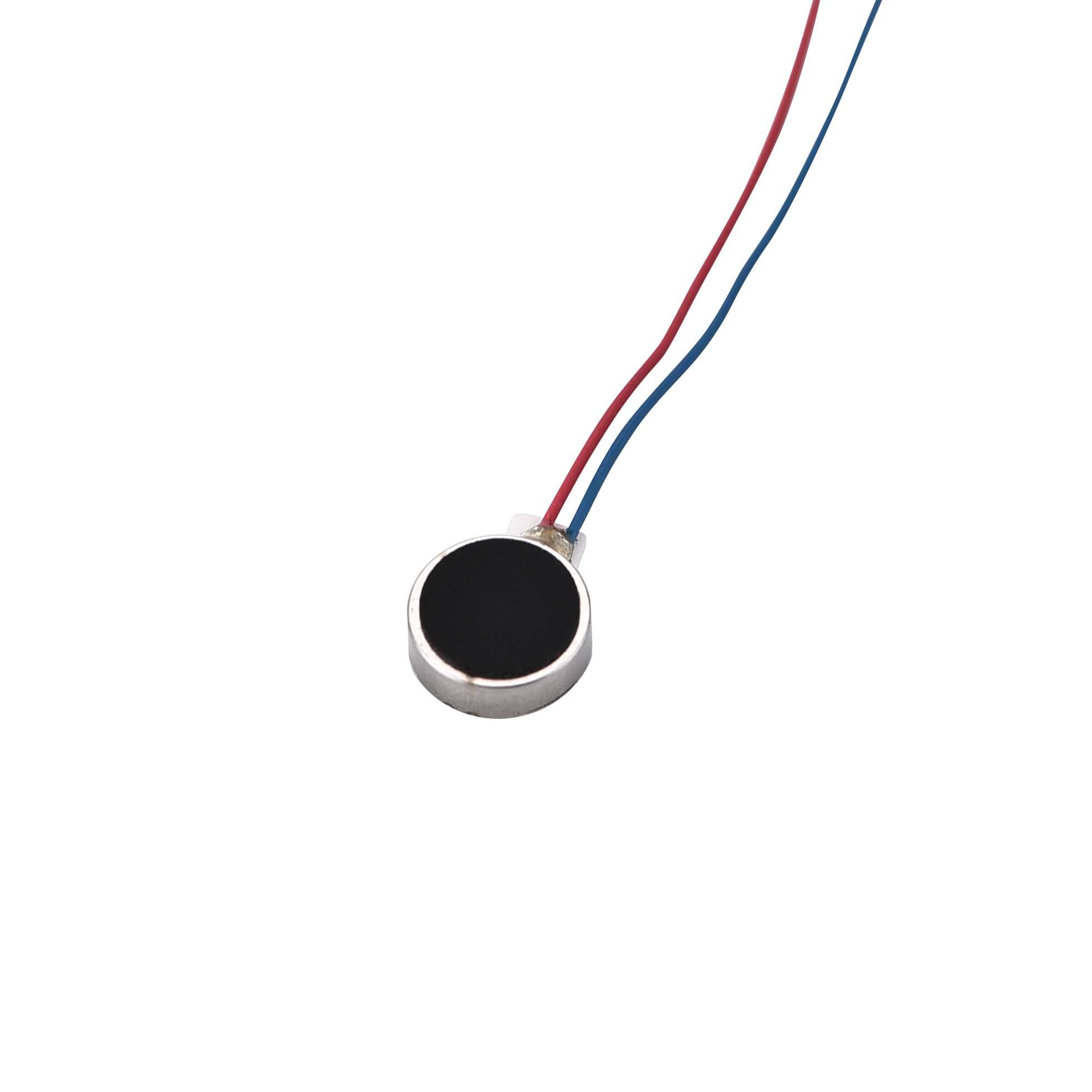

Coin-Type Linear Resonant Actuators

Coin-type LRAs are compact and circular, making them ideal for devices with limited space. These actuators generate vibrations along the z-axis, ensuring precise haptic feedback. Their small size and low power consumption make them a popular choice for wearable devices and smartphones. You can rely on coin-type LRAs when designing products that require minimal energy usage and consistent performance. For example, they are often used in fitness trackers to deliver notifications through subtle vibrations.

These actuators operate at a narrow frequency range, typically between 170 and 180 Hz. This ensures efficient energy use and stable vibration output. Compared to other linear resonant actuator types, coin-type LRAs excel in applications where compactness and energy efficiency are critical.

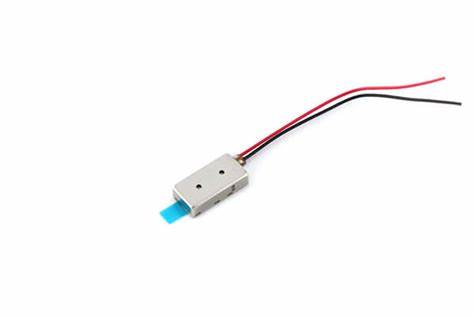

Bar-Type Linear Resonant Actuators

Bar-type LRAs are rectangular and slightly larger than their coin-type counterparts. Their design allows for stronger vibration output, making them suitable for devices requiring more noticeable haptic feedback. You might find bar-type LRAs in gaming controllers or automotive touchscreens, where a more pronounced vibration enhances user interaction.

These actuators share similar characteristics with coin-type LRAs, such as low power consumption and a narrow frequency range. However, their elongated shape provides a higher amplitude, making them a better fit for applications demanding stronger tactile sensations.

Custom LRAs for Specialized Applications

Custom LRAs offer tailored solutions for unique product requirements. You can work with manufacturers to design actuators that meet specific size, frequency, or amplitude needs. This flexibility ensures that your product achieves optimal performance, regardless of its constraints.

For instance, custom LRAs are often used in medical devices, where precision and reliability are paramount. They also play a role in robotics, enhancing tactile feedback for more intuitive control. The table below highlights how LRAs compare to other actuator technologies, emphasizing their advantages in speed and power consumption:

Metric | LRA | Piezo | ERM |

|---|---|---|---|

Speed | Second place | Winner | N/A |

Frequency Response | Narrow range (170-180 Hz) | Wide range (0-500 Hz) | N/A |

Amplitude | Similar to ERM | Similar to LRA | Similar to LRA |

Power Consumption | Low (typically 2V) | N/A | N/A |

Customizing LRAs ensures that your product benefits from the best features of this technology, tailored to your specific application.

Comparison of Linear Resonant Actuator Types

Coin-Type LRAs: Features and Benefits

Coin-type LRAs are compact and lightweight, making them ideal for devices where space is limited. Their circular design supports efficient linear motion along the z-axis, ensuring precise haptic feedback. You can rely on these actuators for applications like wearable devices, where size and energy efficiency are critical. Their low power consumption enhances battery life, which is essential for portable electronics.

These LRAs operate at a narrow resonant frequency range, providing consistent performance. Their accuracy in delivering vibrations ensures a reliable user experience. For example, fitness trackers use coin-type LRAs to deliver subtle notifications. This type of LRA excels in applications requiring minimal energy usage and stable operation.

Bar-Type LRAs: Features and Benefits

Bar-type LRAs are rectangular and slightly larger than coin-type models. Their design allows for stronger vibration output, making them suitable for devices needing more pronounced haptic feedback. You might find these actuators in gaming controllers or automotive touchscreens, where enhanced tactile sensations improve user interaction.

Bar-type LRAs also utilize linear motion to deliver precise vibrations. Their reliability and accuracy make them a preferred choice for applications requiring robust performance. Despite their larger size, they maintain low power consumption, ensuring energy efficiency.

Custom LRAs: Features and Benefits

Custom LRAs provide tailored solutions for unique product requirements. You can collaborate with manufacturers to design actuators that meet specific size, frequency, or amplitude needs. This flexibility ensures your product achieves optimal performance.

Custom LRAs often appear in medical devices, where accuracy and reliability are paramount. They also enhance robotics by improving tactile feedback for intuitive control. A custom LRA ensures your product benefits from the best features of this technology, tailored to your specific application.

Key Performance Metrics for Linear Resonant Actuators

Speed and Response Time

Speed and response time are critical for achieving precise haptic feedback in modern devices. Linear resonant actuators excel in this area due to their ability to reach peak frequency quickly. Unlike ERM actuators, which suffer from slower response times caused by the inertia of their rotating mass, LRAs rely on precise resonant frequencies. This allows them to deliver high-speed motion and crisp vibrations within milliseconds. However, their limited bandwidth restricts the variety of haptic feedback they can produce. You can count on LRAs for applications requiring rapid and accurate tactile sensations, such as wearable devices and electric control systems.

Frequency Range and Resonance

LRAs operate within a narrow frequency range, typically between 170 Hz and 180 Hz. This narrow bandwidth ensures efficient energy use and stable vibration output. However, it also limits their ability to create diverse tactile sensations. Each LRA has a single resonant frequency, which is essential for optimal performance. This precise positioning of the resonant frequency makes LRAs ideal for applications where consistent and reliable haptic feedback is crucial, such as smartphones and medical devices.

LRAs operate within a frequency range of 170 Hz to 180 Hz.

They have one resonant frequency, ensuring stable performance.

The narrow bandwidth can limit the variety of haptic feedback.

Power Consumption and Efficiency

Energy efficiency is a key advantage of LRAs. These actuators consume less power compared to traditional ERM motors, making them suitable for battery-powered devices. However, they require a higher operating voltage to function effectively. The time taken to accelerate to peak frequency and decelerate can also contribute to increased power consumption. Despite these factors, LRAs remain a reliable choice for electric devices where energy efficiency and precise vibration are priorities.

LRAs and ERM actuators consume more power than piezoelectric actuators.

Higher operating voltage is necessary for effective performance.

Acceleration and deceleration times impact overall energy efficiency.

Durability and Lifespan

Durability and lifespan are essential for ensuring long-term performance in electric devices. LRAs have fewer moving parts compared to ERM motors, reducing the risk of mechanical failure. This design enhances their reliability and extends their operational life. You can rely on LRAs for applications requiring consistent performance over time, such as automotive touchscreens and industrial equipment. Their robust construction ensures they withstand repeated use without compromising efficiency or vibration quality.

Application Scenarios for Linear Resonant Actuators

Wearable Devices and Compact Electronics

Linear resonant actuators play a vital role in wearable devices and compact electronics. Their small size and energy efficiency make them an ideal solution for fitness trackers, smartwatches, and health monitoring devices. You can rely on LRAs to deliver precise haptic feedback, such as subtle vibrations for notifications or alerts. This enhances the user experience without compromising battery life. For example, a fitness tracker can use haptic actuators to notify you of your heart rate or step count in real time.

Consumer Electronics and Haptic Feedback

In consumer electronics, LRAs are essential for creating immersive user interactions. Smartphones, tablets, and gaming controllers often use haptic actuators to provide tactile sensations. You might feel a vibration when typing on a virtual keyboard or when receiving a call. This type of haptic feedback improves usability and adds a layer of engagement. LRAs ensure these vibrations are crisp and responsive, making them a preferred solution for modern electronic devices.

Automotive and Industrial Applications

Automotive and industrial sectors benefit from LRAs in control systems and touch interfaces. In vehicles, haptic actuators enhance safety by providing tactile alerts for lane departure or collision warnings. Industrial equipment uses LRAs to improve operator feedback, ensuring precise control in demanding environments. Their durability and reliability make them a robust solution for these applications.

Medical Devices and Precision Equipment

Medical devices require precision and reliability, making LRAs an excellent choice. They provide haptic feedback in surgical tools, diagnostic equipment, and patient monitoring systems. For instance, a handheld ultrasound device can use haptic actuators to guide you during a procedure. This ensures accuracy and enhances the overall functionality of the equipment.

Decision-Making Guide for Choosing the Right LRA

Step 1: Define Your Product's Functional Requirements

Start by identifying what your product needs from an actuator. Consider the type of haptic feedback you want to deliver. For example, wearable devices may require subtle vibrations, while gaming controllers might need stronger tactile sensations. Think about the size, weight, and energy efficiency your product demands. These factors will help you narrow down the most suitable lra type for your design.

Step 2: Evaluate Key Performance Metrics

Examine the critical performance metrics of each lra type. Focus on speed, response time, frequency range, and power consumption. If your product requires quick and precise feedback, prioritize actuators with fast response times. For battery-powered devices, choose an option with low energy consumption. Evaluating these metrics ensures your product performs efficiently.

Step 3: Match LRA Types to Application Scenarios

Align the features of each lra type with your product’s application. Coin-type actuators work well in compact electronics, while bar-type models suit devices needing stronger vibrations. Custom actuators provide flexibility for unique applications like medical devices or robotics. Matching the right type to your use case ensures optimal performance.

Step 4: Balance Cost, Performance, and Design Constraints

Weigh the cost of the actuator against its performance and your design limitations. High-performance actuators may cost more but could enhance user experience. Consider your budget and prioritize features that align with your product’s goals.

Step 5: Test and Validate with INEED's Linear Vibration Motors

Testing is essential to ensure the actuator meets your expectations. Use INEED’s linear vibration motors to validate your design. Their precision and efficiency make them a reliable choice for diverse applications. Testing helps you refine your product and achieve the best results.

Understanding the unique characteristics of linear resonant actuators helps you make informed design decisions. INEED's Linear Vibration Motors offer precise and efficient solutions for a wide range of applications.

Use the decision-making guide to match the right LRA type to your product. This ensures optimal performance and enhances user experience.

FAQ

What makes piezoelectric actuators different from LRAs?

Piezoelectric actuators use piezo materials to create motion through electrical stimulation. LRAs rely on a voice coil and spring mechanism for vibration. Both offer unique advantages.

How do integrated actuators improve performance in devices?

Integrated actuators combine multiple components into one system. This design reduces complexity, enhances efficiency, and ensures improved performance in applications requiring precise motion control.

Why are linear actuator systems ideal for haptic feedback?

Linear actuator systems provide high repeat accuracy and constant positioning accuracy. These features ensure advanced haptic effects and reliable tactile sensations in modern devices.

See Also

LRA Vibration Motors: Key Drivers of Haptic Feedback Technology

Investigating How Vibration Motors Are Used Across Industries

An Overview of Top Instruments for Measuring Vibration

Understanding Haptic Feedback: Uses, Advantages, and Future Trends

The Impact of Haptic Steering Wheels on Driver Safety and Comfort

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry