How to Choose the Best Small DC Motor and Gear for Your Project

Choosing the right small DC motors and gears is important. Picking the wrong ones can cause problems like overheating or failure. Think about key factors such as torque, speed, and voltage. The environment where the motor operates also matters significantly. For example, robots require small DC motors and gears that are very accurate, while machines in factories need motors that are durable and long-lasting. Following a step-by-step process helps you select the right small DC motors and gears, saving time and enhancing the reliability and performance of your project.

Key Takeaways

Know what your project needs before picking a motor. Think about torque, speed, and voltage to match your project.

Pick the right gear type for your project. Use planetary gears for strong power or spur gears for cheaper options.

Try out the motor and gear in real situations. This helps find problems and makes sure they work well under pressure.

Take care of the motor to make it last longer. Check parts like brushes and bearings to avoid problems and keep it running smoothly.

Look at energy use and work time when choosing motors. Efficient motors save power and money, and matching work time helps them perform better.

Basics of Small DC Motors and Gears

Overview of Small DC Motors

Small DC motors are important in today's technology. They change electrical power into movement, making them useful for robots, gadgets, and machines. Their small size helps them fit in tight spaces. They also work well with low voltage, perfect for portable devices.

These motors have features like adjustable speed and high efficiency. Many can reach up to 91% efficiency, wasting little energy. Torque and speed are key factors. Some motors provide 10 mNm torque and keep a steady speed of 200 rpm. This makes them great for precise and repeated tasks.

Types of DC Motors

There are different types of DC motors for various uses. Shunt motors give steady speed and high torque, good for factory work. Series motors are best for jobs needing strong starting power, like cranes. Compound motors mix the benefits of shunt and series motors, making them useful for elevators and mills.

Brushless DC motors are efficient and last longer. They need less care and have advanced features like sensors for better performance. These motors are used in electric cars and airplanes. They save energy, making them popular for modern projects.

Type of DC Motor | Torque Features | Speed Control | Uses |

|---|---|---|---|

Shunt Motor | High torque at any speed | Great speed control | Factory tasks |

Series Motor | Strong starting torque | Weak speed control | Cranes, trains |

Compound Motor | Mixed torque benefits | Okay speed control | Elevators, mills |

Importance of Gears in Motor Systems

Gears improve small DC motors by changing torque and speed. This helps motors work well under different loads, giving smooth and accurate motion. For example, worm gears are 49% to 90% efficient, depending on their setup. Helical bevel gears, with up to 97% efficiency, are great for crossing axes tasks.

Choosing the right gear can save money. A helical worm gear system can save $143 yearly compared to older worm gears. Gears are key to making motor systems work better and use less energy.

Gear Type | Efficiency Range (%) | Ratio Type |

|---|---|---|

Worm Gear | 49% to 90% | Single or Double |

Helical Bevel | 94% to 97% | Crossing Axes |

In-line Helical | 95% to 98% | Straight In-line |

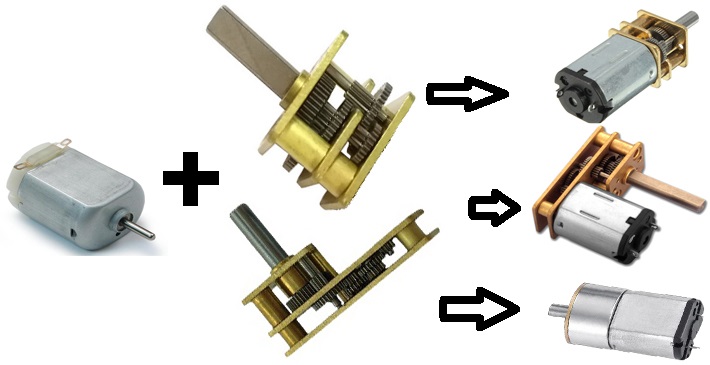

Types of Gears for DC Motors

Gears are important for improving how DC motors work. They change torque and speed, helping motors perform better in various tasks. Picking the right gear depends on what your project needs, like torque, speed, or strength.

Spur Gears

Spur gears are simple and low-cost. They have straight teeth and are best for low-torque jobs. These gears are good for projects where noise and shaking don’t matter much. For example, they are used in toys and small devices.

Advantages:

Easy to make and fix.

Cheap for projects with tight budgets.

Planetary Gears

Planetary gears are more advanced and give higher torque. They include a sun gear, planet gears, and a ring gear. This setup helps them handle heavy loads well. You’ll see these gears in robots and factory machines.

Advantages:

Small size but strong torque.

Great for high-power tasks.

Material Considerations

The gear material affects how strong and efficient it is. Steel gears last the longest, making them great for high-torque needs. Nickel-steel gears hold oil better, which reduces damage over time.

Parameter | Value | Unit |

|---|---|---|

No-Load Speed | 58 | rpm |

Rated Torque | 2.5 | Nm |

Max. Efficiency | 43 | % |

Stall Torque | 15 | Nm |

Tip: For precise and strong projects, use steel planetary gears. For easier tasks, spur gears are a good pick.

Knowing about gear types and their benefits helps you choose wisely. This ensures your project works well and lasts a long time.

Step-by-Step DC Motor Selection Process

Define Project Requirements

The first step is to know your project’s needs. Think about what the motor will do. Will it move a robot, run a conveyor belt, or power a small gadget? Different tasks need different motors. For example, a micro DC gear motor works well for tiny devices. A 12V DC gear motor fits medium-sized machines.

Next, list what your project needs. This includes torque, speed, and power. Torque shows how much weight the motor can handle. Speed decides how fast it works. If your project needs precise movements, pick a motor with good speed control. Also, check voltage and current needs. A 12V DC gear motor works with common power supplies.

Think about the load the motor will carry. Find out the weight or resistance it must overcome. For example, in robots, you might need to account for the weight of parts like an exoskeleton. Follow these steps:

Write down user needs and settings.

Measure the weight of moving parts.

Use sensor data to figure out torque needs.

Test if the motor fits your project.

This method helps the motor work well without failing or being too weak.

Tip: Always set clear goals and limits before picking a motor. This saves time and avoids mistakes.

Assess Environmental and Operational Constraints

Where and how the motor works affects its performance. Think about conditions like temperature, moisture, or dust. For example, outdoor motors may need protection from water and dirt.

Constraint Type | Things to Consider |

|---|---|

Temperature | Can the motor handle hot or cold conditions? |

Water | Will it face splashes or be underwater? |

Dirt | Is there exposure to dust or debris? |

Corrosion | Will it deal with chemicals or rust? |

Serviceability | Is it easy to fix or replace the motor? |

Installation | Are there special setup or storage needs? |

Size | Does the motor fit the space available? |

Cooling | Does it need extra cooling for heat? |

Weight | Does the motor’s weight affect the system’s balance? |

For example, a factory motor in dusty areas should be sealed to avoid damage. Motors near water need an IP rating for splash or submersion protection.

Note: Ignoring conditions can cause motor failure or poor performance. Match the motor to its environment.

Match Motor Specifications to Project Needs

After knowing your needs and limits, compare motor specs to your project. Look at torque and speed ratings. For heavy loads, pick a DC gear motor with the right gear ratio. Planetary gears are small but strong, great for robots.

Check the inertia ratio (Jl < Jm). Keeping load inertia lower than the motor’s inertia ensures smooth operation. This is key for tasks needing accuracy, like turning rotary motion into straight-line motion.

Also, review the motor’s power and frequency abilities. Some systems, like Navigator II, handle up to 30 kW power and 60 MHz frequency. These features suit many uses, from factory machines to home gadgets.

Finally, look at control options. Does the motor allow speed changes or feedback? These features improve performance and let you adjust during use.

Pro Tip: Use tools like torque calculators or simulations to check the motor fits your project. Testing avoids mistakes and ensures top performance.

Select the Right DC Gear Motor and Ratio

Picking the right DC gear motor and ratio is very important. It ensures your project works as planned. Start by deciding if you need steady or changing speed. For example, conveyor belts need steady speed. Robotic arms may need speed that changes.

Next, think about torque. Torque is the force the motor uses to move things. Heavy lifting needs a motor with high torque. Light tasks can use a motor with lower torque. Also, check how often the motor will run. If it runs all the time, pick a durable one. If it runs sometimes, you have more options.

The gear ratio is key to balancing torque and speed. A high gear ratio gives more torque but less speed. This is good for lifting heavy things. A low gear ratio gives more speed but less torque. This works for spinning fans or wheels. Knowing this helps match the motor to your project.

Look at performance curves to refine your choice. These curves show how speed, torque, and efficiency work together. Pick a motor that works best at the speeds you need. For example, if you need high efficiency at medium speed, choose a motor with a peak curve in that range.

Tip: Use tools like torque calculators to see how gear ratios affect the motor. This saves time and avoids mistakes.

Test and Validate the Selection

After choosing the motor and gear ratio, test them to ensure they work. Set up a test area to mimic real conditions. Use tools like data systems to check speed, vibration, and noise. These tests show how the motor performs under pressure.

Automation can make testing easier. A programmable controller can run tests automatically. For example, it can measure torque and speed at different loads. This gives a full picture of how the motor works.

Advanced systems, like Signalysis, provide extra details. They check vibration, sound, and movement to ensure quality. These systems also give pass/fail results. If the motor vibrates too much, it will be flagged for fixing.

Testing also checks for common issues like speed limits and power use. Compare test results to what you expect. This ensures the motor works within safe limits. This is very important for precise tasks like robots or cars.

Note: Always keep records of your tests. These help solve problems and guide future projects.

Key Considerations for Small DC Motors and Gears

Torque and Speed Balance

Finding the right balance between torque and speed is important. Torque is the force a motor uses to move something. Speed is how fast the motor spins. For small DC motors and gears, this balance helps the motor work well without wasting energy.

To check this balance, test the motor with different loads. Start with a light load and measure the torque and speed. Slowly increase the load and see how the motor reacts. This shows what the motor can handle and if it fits your project.

Parameter | Description |

|---|---|

T | |

(\omega_{m}) | Speed of the motor shaft |

J | How hard it is to change speed |

B | Friction inside the motor |

K | Torque constant of the motor |

For precise tasks, changing the gear ratio is helpful. A ratio like 48:1 increases torque but lowers speed. This is great for jobs needing strong force and slow, steady motion. It also saves energy by reducing power waste.

Tip: Look at performance graphs to see how torque and speed work together. This helps you pick the best motor.

Voltage and Power Supply Needs

The motor’s voltage and power supply are very important. Using the right voltage and current keeps the motor reliable and efficient. For example, a 12V DC gear motor works well for many medium-sized projects because it matches common power sources.

Specification | Why It Matters |

|---|---|

Shows the needed voltage for your project. | |

Maximum output current (Iout) | Helps you know the motor’s power needs. |

Output regulation / ripple | Affects performance when loads change. |

Temperature grade | Keeps the motor working in hot or cold places. |

Derating | Adjusts for conditions that lower power efficiency. |

Think about where the motor will be used. Motors in hot or cold places need strong power supplies. For example, outdoor motors may need higher temperature ratings to work properly.

Note: Always check the motor’s voltage and current limits to avoid overheating or poor performance.

Size and Mounting Limitations

The motor’s size and how it mounts are key factors. It must fit in the space you have and handle the load.

Frame Size | Shaft Height (inches) | Common Uses |

|---|---|---|

143T | 3.5 | Small pumps, home water systems, small irrigation setups |

215T | N/A | Medium pumps, cooling systems, process water systems |

326T | N/A | Large pumps, industrial water systems, city water treatment plants |

For small designs, choose motors with smaller frames. For example, a 143T frame size is good for small pumps or home systems. Also, make sure the motor’s mounting matches your design. Bad mounting can cause misalignment, wasting energy and wearing out parts.

Pro Tip: Measure your space and mounting spots before picking a motor. This avoids expensive changes later.

Energy Efficiency and Duty Cycle

Energy efficiency is key for small DC motors to work well. Using an efficient motor saves energy and cuts costs. Look for motors with high ratings from groups like the IEC and NEMA.

Standard | What It Means |

|---|---|

IEC | Sets global efficiency levels for motors |

NEMA | North America's efficiency rules for motors |

The duty cycle affects how efficient a motor is. Different projects need different duty cycles. Continuous duty cycles are best for nonstop tasks like conveyor belts. Short-term duty cycles work for quick jobs, like robotic arms. Periodic duty cycles mix work and rest, good for things like automatic doors.

Continuous duty cycles

Short-term duty cycles

Periodic duty cycles

Pick a motor with the right duty cycle for your project. For example, a motor made for nonstop use won’t last if used in short bursts. Matching the duty cycle improves performance and makes the motor last longer.

Tip: Always check the motor’s efficiency rating and duty cycle before buying. This helps save energy and money.

Maintenance and Durability

Taking care of your motor keeps it working longer. Regular checks stop big problems before they start. Look at brushes and the commutator often to avoid issues. Listen for strange noises or vibrations, as these may mean trouble.

Listen for noise or vibration in bearings.

Test insulation resistance regularly.

Keep vents and cooling areas clean.

Watch motor temperature during use.

Tighten all electrical parts.

Align the motor and load properly.

Lubricate bearings as the maker suggests.

Use the right protection devices.

Write down all maintenance work.

Aligning the motor and load reduces wear and boosts efficiency. Lubricating bearings keeps the motor running smoothly. Cleaning vents stops overheating, which can break the motor.

Note: Keep maintenance records to track how the motor is doing. This helps plan repairs and saves money over time.

Applications of Small DC Motors and Gears

Robotics and Automation

Small DC motors and gears are key in robotics. They boost efficiency and reduce mistakes, helping industries like healthcare and manufacturing. For example, a planetary gear motor gives high torque in small spaces. This makes it perfect for robotic arms and precise machines.

New technology has made these motors even better. Brushless DC motors last longer and save energy. They are great for tasks needing exact control. Stronger gear materials also make them more reliable in tough conditions.

Automation increases the need for small motors in robots.

Energy-saving motors are great for low-power tasks.

Brushless motors are used in advanced technology projects.

These features make small DC motors and gears vital for robotics. They ensure smooth work and long-lasting performance.

Consumer Electronics

Small DC motors and gears are common in electronics because they are small and precise. For example, a micro servo motor in medical devices works at low voltage. It controls flow rates accurately, meeting strict quality needs.

In gadgets like cameras and printers, brushed DC motors give smooth motion. Brushless motors are better for tasks like cooling fans. They save energy and need less care.

Gear Type | Diameter (mm) | Max Torque (Nm) | Uses |

|---|---|---|---|

Spur Gearset | 51 | 3.5 | Affordable and general-purpose tasks. |

Planetary Gearset | 52 | 24 | Compact, high-torque uses like precision machines. |

Brushed DC Motor | N/A | Up to 30 W | Used in medical tools, robots, farming, and food-service machines. |

Brushless DC Motor | N/A | N/A | Ideal for precise tasks, fans, and pulleys. |

These motors and gears work well in many electronics, ensuring they perform reliably.

Automotive and Transportation

Small DC motors and gears are important in cars and transport. They power things like wipers, windows, and seat adjusters. A spur gear motor is affordable and balances speed and torque for these tasks.

In electric cars, brushless motors help with steering and cooling fans. They save energy and last long, making them great for short tasks.

Planetary gears are used in automatic transmissions. They give high torque in small designs, making driving smoother and more reliable.

Small DC motors and gears meet strict needs in cars, ensuring safety, comfort, and efficiency.

Industrial and Manufacturing Equipment

Small DC motors and gears are important in factories. They work well for tasks needing accuracy and dependability. For example, conveyor belts use small DC gear motors to keep movement smooth. These motors balance torque and speed, which helps production lines run efficiently.

These motors save energy too. Their brushless design lowers friction, using less power and lasting longer. This is helpful for machines like air conditioning fans that need strong torque at slow speeds. The gears in these motors boost torque and improve power transfer. This makes them great for high-power jobs like automated assembly lines.

Another benefit is they need little care. Replacing brushes is easy, keeping the motor running longer. You can also change gear ratios to get the torque and speed you need. For example, slowing the motor’s shaft with gear reduction gives better control for precise machines.

Tip: Pick a motor based on torque, speed, and energy use. This ensures it works well and lasts long.

DIY and Hobbyist Projects

Small DC motors and gears are great for DIY projects because they are flexible and affordable. Whether building a robot or smart car, these motors can be customized to fit your needs. You can choose different shaft types and gear ratios for your project.

One great feature is they are quiet. This makes them perfect for projects in quiet places, like home automation systems. They also use little energy, making your project more efficient without wasting power.

Feature | Description |

|---|---|

Cost | |

Performance Curve | Shows how torque and speed affect efficiency. |

Customization | Offers options like different shafts and gear ratios. |

Noise Level | Quiet operation, good for peaceful environments. |

Energy Consumption | Uses less energy, improving project efficiency. |

Service Life | Long-lasting, great for DIY projects. |

Application | Perfect for robots, smart cars, and creative DIY ideas. |

These motors last a long time, keeping your projects working for years. By studying the performance curve, you can adjust torque and speed to fit your needs. Small DC motors and gears are a dependable choice for hobbyists creating new ideas.

Note: Check things like noise and energy use to pick the best motor for your DIY project.

Picking the best small DC motors and gears begins with knowing your project. Understand what your project needs, like torque, speed, and conditions. Testing shows how the motor works in real situations. Validation helps prevent expensive errors. Following clear steps makes choosing easier and boosts reliability. By doing this, your motor will work well and last longer.

FAQ

What matters most when picking a small DC motor?

Think about your project’s torque and speed needs. These decide how well the motor works with a load. Always match the motor’s details to your project for the best results.

How can I find the right gear ratio?

Divide the speed you want by the motor’s speed. For example, if the motor spins at 3000 rpm but you need 300 rpm, the gear ratio is 10:1. Online tools can make this calculation faster.

Can one motor work for different projects?

Yes, but only if it fits each project’s torque, speed, and environment needs. For instance, a motor for a robot might not suit a conveyor system because of different loads.

How can I make my motor last longer?

Take care of it regularly. Clean vents, oil bearings, and check for odd noises or shaking. Align it properly and avoid overloading to keep it working longer.

What’s the difference between brushed and brushless DC motors?

Brushed motors use brushes to work, making them cheaper but less durable. Brushless motors use electronics, so they last longer and are more efficient. Pick one based on your budget and project needs.

Tip: Choose brushless motors for long-lasting, high-performance tasks.

See Also

Guidelines for Selecting a Planetary Gear Motor for Precision

Choosing Ideal Mini DC Motors for Industrial Use

How to Pick a 3 Volt DC Motor for Projects

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry