How to Choose the Right Precision Electric Motor for Your Needs

When you pick precision electric motors, you must match their features to your job. This choice affects how well your machines work and how much you pay for power and repairs.

If you pick the right motor size, you save energy and stop your machines from breaking.

Energy-efficient electric motors cut your power bills and are better for nature.

The right mounting and frame size stop shaking and help your system work well.

Thinking about the area and space keeps your electric motor safe and helps it last longer.

Choosing the right motor gives you good results and saves you money in the long run.

Key Takeaways

Make sure the motor's torque and speed fit your job. This helps keep things safe. It also makes the motor work well and last longer.

Think about where the motor will be used. Check if it will face heat, dust, or water. Pick the right protection to stop damage.

Choose the right motor size for your needs. This saves energy and lowers wear. It also stops expensive repairs from wrong sizing.

Use a simple checklist or online tools to compare motors. Look at types, power, voltage, and how they are mounted. This helps you find the best one.

Buy motors from trusted brands and do regular maintenance. This keeps them working well and stops surprise breakdowns.

Define Application Needs

Load and Torque

When you pick an electric motor, you need to know the load and torque. Torque is the force that spins the motor shaft. You must match the torque to your job. This keeps your machine safe and working well. Different jobs need different torque levels. Cars and construction machines need high torque. This stops parts from coming loose or breaking. In factories, there are four main load types:

Variable horsepower and constant torque (like conveyors and cranes)

Variable torque and constant horsepower (such as web rewind machines)

Variable horsepower and variable torque (for fans and mixers)

Positional or torque control (used in actuators and presses)

You should use simple math to find torque. Most machines use T = Force × Radius. For a robotic arm, multiply the weight by gravity and then by the distance from the joint. Always add 20-30% more torque for safety. This helps your electric motor handle changes in load. It also keeps your system safe.

Tip: Use torque sensors and strain gauges to check real torque. This helps you meet your needs and avoid mistakes.

Speed (RPM)

Speed is measured in revolutions per minute (RPM). You need to know how fast your machine should go. Most electric motors work best between 800 and 1800 RPM for steady jobs. Some motors, like inverter duty types, can go from zero up to 3000 RPM or more. This lets you control speed and torque for many uses.

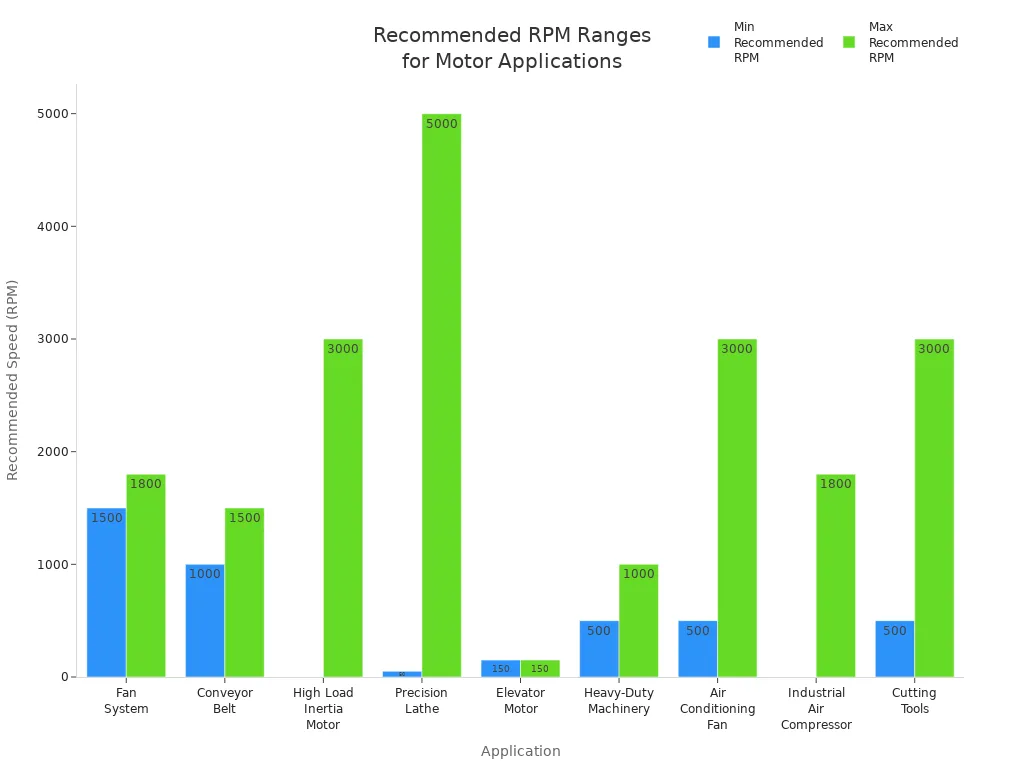

Application | Recommended Speed Range (RPM) | Notes/Details |

|---|---|---|

Fan System | 1500 - 1800 | Example: fan providing 5000 m³/h airflow, design speed 1500 RPM |

Conveyor Belt | 1000 - 1500 | Speed requirement ~5 m/min, load ~200 kg |

High Load Inertia Motor | 0 - 3000 | High starting torque needed, output requirement 3000 RPM |

Precision Lathe | 50 - 5000 | Stable, slow running; CNC motors adjust smoothly between 1000 - 5000 RPM |

Elevator Motor | ~150 | For 1000 kg load at 1 m/s speed |

Heavy-Duty Machinery | 500 - 1000 | Example: mining excavators |

Air Conditioning Fan | 500 - 3000 | Typical fan motor speed range |

Industrial Air Compressor | Up to 1800 | Operating speed ~1500 RPM, load pressure 10 bar |

Cutting Tools | 500 - 3000 | Wood cutting ~1000 RPM, metal cutting ~1500 RPM |

If a motor runs too fast, it can get too hot and wear out. High speeds mean more current and heat. This can hurt insulation and bearings. Always check the insulation class and temperature limits for your electric motor. This helps you meet your needs and keeps your motor working longer.

Environment

You need to think about where you will put your electric motor. Temperature, humidity, dust, and water can all affect how long your motor lasts. Motors in hot places need special insulation and cooling. Motors in wet or dusty places need covers and high IP ratings to keep out water and dirt.

Temperature affects how long your motor can run before it gets too hot.

Humidity can cause rust and corrosion. This can damage bearings and windings.

Dust and dirt can block cooling and make the motor overheat.

Food and drink factories need motors made from stainless steel. This helps them resist spills and rust.

Note: Motors with good seals and coatings last longer in tough places. Always check your needs for climate and exposure.

Space and Installation

Space is important when picking a motor. You need to measure where you want to put your electric motor. Small spaces need small motors and special ways to mount them. Vertical mounting saves floor space but may need extra care for oil and bearing loads. Flange and face mounting let you connect the motor right to your machine. This saves even more space.

In tight spaces, you may need motors with axial flux designs. These motors fit inside wheels or small machines, like electric bikes or vehicles. Always match your motor type to your space and needs. This helps you avoid problems and makes your system easier to take care of.

Types of Precision Electric Motors

When you choose precision electric motors, you need to know the main motor types and how they work. Each type has its own strengths and best-fit applications. Let’s look at the most common options.

Stepper Motors

Stepper motors move in small, fixed steps. You control them with simple signals, and you do not need feedback. This makes them easy to use and cost-effective. Stepper motors hold their position well at low speeds, which helps in 3D printers and scientific tools. They can lose steps if the load is too high, and their torque drops at high speeds. You should pick stepper motors for jobs that need precise positioning but not high speed or changing loads.

Characteristic | Stepper Motors | Servo Motors |

|---|---|---|

Open-loop, no feedback | Closed-loop with feedback | |

Accuracy | Good at low speeds, can miss steps | High accuracy and repeatability |

Speed and Torque | High torque at low speeds, drops at high speeds | Maintains torque at high speeds |

Cost | Lower | Higher |

AC and DC Motors

AC and DC motors form the base for many precision electric motors. AC motors work well in factories and large machines because they handle high power and keep torque at high speeds. DC motors are smaller and easier to control, so you find them in portable devices and small robots. Brushless DC motors last longer and use less energy because they have no brushes to wear out.

Tip: If you want the best mix of cost and performance, match the motor type to your job’s needs. Servo motors give you top precision, while stepper motors save money for simple tasks.

Electric Motor Selection Criteria

Power and Efficiency

When you pick an electric motor, check its power and efficiency. Power shows how much work the motor can do. Efficiency tells you how well it changes electricity into movement. Motors with high efficiency waste less energy as heat. This saves you money and helps the motor last longer.

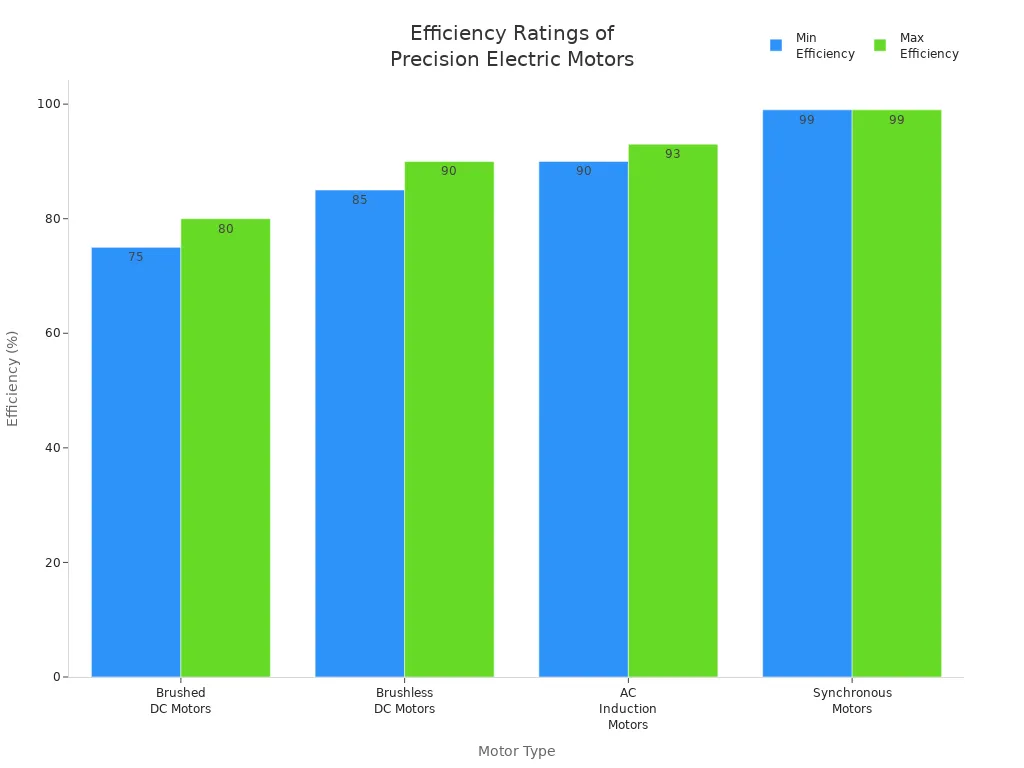

You can look at efficiency ratings for different motors. The table below shows the usual efficiency range for each type:

Motor Type | Efficiency Range (%) | Key Efficiency Factors and Notes |

|---|---|---|

Brushed DC Motors | 75 - 80 | Least efficient; efficiency improves with higher speeds; uses brushes and commutator for current flow. |

Brushless DC Motors | 85 - 90 | Higher efficiency due to permanent magnet rotor and electronic commutation; reduced slip between rotor and stator. |

AC Induction Motors | 90 - 93 | Efficiency depends on speed variability and stator pole count; inherent slip causes asynchronous lag. |

Synchronous Motors | Up to 99 | Near-perfect conversion; no rotor current needed; synchronized magnetic field and current frequency; compact design. |

The rated power is the most a motor can give at the shaft. The real power used changes with the load. If you add more load, the motor uses more current and power. With no load, it uses less power, but some energy is always lost as heat and friction. Both AC and DC motors act this way. To save energy, pick a motor with high efficiency that fits your needs.

The motor’s input power goes up as the load gets bigger.

Fixed losses stay the same, but total power use rises with more load.

You can see this when a lamp dims as a motor starts with a heavy load.

Voltage and Compatibility

You must check voltage and compatibility before using an electric motor. The voltage must match your power supply. If you use the wrong voltage, the motor might not work or could break. The table below shows common voltage and frequency standards:

Region | Voltage Standard | Frequency Standard |

|---|---|---|

North America | 230/460 V | 60 Hz |

Europe | Varies (IEC) | 50 Hz |

Voltage compatibility helps you connect the motor safely and easily. Using higher voltage lets the motor give more power with less current. This means you can use smaller wires and lose less energy as heat. For example, moving from 12V to 48V in vehicles makes the system safer and more efficient. High voltage systems also let you use features like electric power steering.

Note: Always match the motor voltage to your system voltage. This helps avoid problems and keeps your system safe.

High voltage connection systems are made for easy setup. They save time during installation and work well in tough places. Modular designs help you build and upgrade your system faster. Voltage compatibility is very important for your needs.

Duty Cycle and Maintenance

Duty cycle tells you how long and how often the motor runs. Some motors run all day, while others start and stop many times. You need to pick a motor that fits your needs for duty cycle.

Continuous Duty (S1): The motor runs at a steady load until it gets to normal temperature. This is good for things like escalators or packaging machines.

Intermittent Duty (S3): The motor runs in short bursts with breaks. This keeps the motor from getting too hot. You can use a smaller motor for these jobs, like conveyors that start and stop a lot.

Continuous Duty with Load Variations (S8): The motor runs all the time but with changing loads and speeds. This is common in factories.

Continuous Duty with Electric Braking (S7): The motor starts, runs, and then brakes often. This is good for robots and moving materials.

Good cooling is important for all duty cycles. If you pick the wrong motor for your duty cycle, it may get too hot or wear out fast.

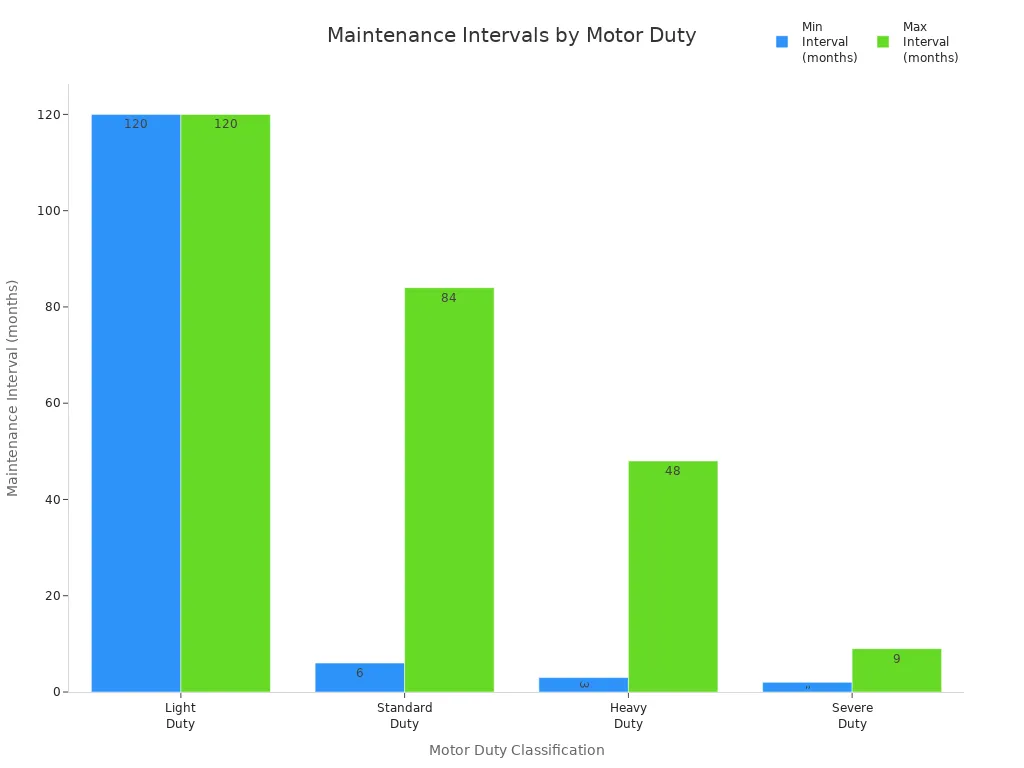

Maintenance needs change with how hard the motor works. The table below shows how often you need to check and service different motors:

Motor Duty Classification | Operating Conditions Description | Maintenance Interval Frequency |

|---|---|---|

Light Duty | Motors operate infrequently (about 1 hour/day or less) in applications like portable floor sanders, valves, door openers. | Maintenance intervals can be as long as 10 years for small motors, decreasing with motor size. |

Standard Duty | Motors operate in normal applications (1-2 shifts), e.g., air conditioning units, conveyors, pumps. | Maintenance intervals range from 6 months to 7 years depending on motor size. |

Heavy Duty | Motors run continuously (24/7/365) under harsh conditions with above normal vibration, e.g., steel mill service, mining machinery, motor-generator sets. | Maintenance intervals are significantly shorter, e.g., 3 months to 4 years depending on motor size, reflecting more frequent inspections and servicing. |

Severe Duty | Extremely harsh, dirty environments with severe vibration and high ambient conditions. | Maintenance intervals are the shortest, e.g., 2 to 9 months, requiring the most frequent and intensive maintenance. |

Heavy-duty motors need checks every three months. You must inspect, oil, and clean them often. Light-duty motors can go years without much care. Always follow the maintenance schedule for your motor’s duty class.

Reliability

Reliability means the electric motor will work well for a long time. You want a motor that does not break often and can handle your job. You can measure reliability in different ways:

Mechanical integrity testing checks for shaking and vibration problems.

Thermal behavior mapping shows how the motor deals with heat.

Core loss tests measure energy lost at different speeds and loads.

You can also look at these reliability numbers:

Accuracy, recall, and precision for fault detection systems.

F1 score, which balances precision and recall.

Importance degree of motor parts, risk priority number (RPN), and mean time to failure (MTTF).

Average lifetime from tests and vibration influence numbers.

Brand reputation matters too. The table below compares warranty periods and failure rates for top brands:

Brand Type | Warranty Period | Failure Rate (approx.) | Additional Notes |

|---|---|---|---|

Baldor (leading) | 1 to 10 years | Very low | High build quality; some motors last 35+ years |

Import Motors | Typically 1 year | Around 5% within warranty | Often Chinese-made; higher failure rates |

Motors from top brands like Baldor can last for decades and rarely fail. Import motors may break more often and have shorter warranties. How you use the motor, like overloading and wiring, also affects reliability. When you pick a motor, always think about reliability as a key need.

Match Features to Application

Practical Checklist

When you want to select motors for your project, you need a clear checklist. This helps you match the right features to your application. Follow these steps to make a smart choice:

Analyze your needs. Write down the power, speed, and torque your application requires.

Choose the right motor type. Decide if you need AC, DC, stepper, or servo motors based on how your machine works.

Check voltage and current ratings. Make sure the motor matches your power supply and can handle the load.

Confirm the power rating. Pick a motor with enough wattage for your workload.

Match torque and speed. Look at the torque and RPM to see if they fit your job.

Review mounting and size. Measure your space and check if the motor fits.

Think about the environment. If your application is in a wet, dusty, or hazardous place, pick a motor with the right protection.

Focus on energy efficiency. Motors that use less power save money and last longer.

Check for safety and certifications. Look for ISO or other marks that show quality.

Compare brands and suppliers. Choose companies with good reputations and strong support.

Test samples if possible. Try out motors before you buy many.

Ask about after-sales service and warranty. Good support helps if problems come up.

Tip: For special needs, look for motors with advanced designs like PCB stator technology. These can be customized for unique shapes, cooling, or winding patterns.

Online Tools

You can use online tools to help you pick the best motor for your application. The Festo Electric Motion Sizing Tool lets you enter details like load, motion cycle, and timing. It then suggests motors that fit your needs. You get product data, settings, and connection tips. This tool saves time and helps you compare options quickly. Always review the results and check if the suggested motors meet your checklist.

Avoid Mistakes Choosing the Right Motor

Picking the right motor is important. If you make mistakes, you can lose money and time. Your machines might stop working. You need to think about size, where you use it, and how it fits with other parts.

Over/Under-Sizing

Some people guess the motor size instead of doing math. This can cause big trouble. A motor that is too small cannot handle the job. It gets too hot and breaks a lot. It will not last very long. A motor that is too big wastes energy. It costs more to buy and fix. You pay more for repairs and use more power.

Big motors use more energy and get hotter. This makes parts wear out faster.

Small motors work too hard and get too hot. They break down and stop your work.

The right size motor saves energy and money. Your machines last longer.

Tip: Always figure out the torque and speed you need. Do not guess. Pick a motor that matches your job and how often you use it.

Ignoring Environment

You must think about where you put the motor. If you forget this, your motor can break sooner. Motors in hot, wet, or dirty places need special covers.

Hot places make motors wear out faster.

Dust and dirt can make gears stop working.

Wet places cause rust and damage insulation.

Motors without good covers let in water and dirt. This can break them.

Environmental Factor | Possible Problem | Solution |

|---|---|---|

High Temperature | Shorter motor life | Use motors with better cooling |

Dust/Debris | Gears and bearings break | Pick sealed motors (IP65+) |

Moisture | Rust and insulation damage | Use corrosion-resistant motors |

Note: Pick motors with the right covers for your space. Clean and check them often to stop problems.

Integration Issues

Your motor must work with your control system. If you do not check this, you can have errors or your system may not work.

Make sure your motor uses the same signals as your control system, like Profinet or Modbus.

Check if feedback devices like encoders fit your system.

Test if the motor works before you install it.

Ask the maker for help if you are not sure.

Use motors with common connectors for easy setup.

Tip: When your motor fits your control system, it works better. Upgrades are easier in the future.

If you avoid these mistakes, you pick the right motor. You save money and time. Your machines work well for many years.

When you pick a motor, take your time with each step. Make a list of what you need. Look at different motor types and compare them. Use checklists or online tools to help you decide. Many companies show that the right motor for the job saves money and stops problems. Brushless DC motors are good for jobs that need precision and little upkeep. If your project is hard, ask an expert for help. Experts can help you pick the best motor, controls, and setup so your project works well for a long time.

FAQ

What is the most important factor when choosing a precision electric motor?

You should focus on matching the motor’s torque and speed to your application. If you get these right, your machine will work well and last longer.

How do you know if a motor is energy efficient?

Look for the efficiency rating on the motor’s label or datasheet. High-efficiency motors waste less energy as heat. You can also check for certifications like NEMA Premium.

Can you use any motor in a wet or dusty environment?

No. You need a motor with a high IP rating and special seals. These features protect the motor from water and dust. Always check the environment before you choose.

What happens if you oversize your motor?

If you pick a motor that is too big, you waste energy and money. The motor will cost more to buy and run. Your system may also become less efficient.

Where can you find help if you are unsure about motor selection?

You can use online sizing tools or contact motor suppliers. Many companies offer expert advice and support. This helps you make the right choice for your project.

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry