Top Tips for Choosing the Best High Torque DC Electric Motor for Your Project

If you want to pick the right motor, first know what you need. Think about how much torque, RPM, and load your project needs. Some people make mistakes by skipping these steps. Some do not check if their dc electric motor high torque fits the power source and place. You should also think about size, how to install it, and how well it works. Picking the best dc electric motor high torque means looking at every detail, not just the numbers.

Key Takeaways

Figure out how much torque your project needs by using force and radius. Add extra torque to be safe, so your motor can handle the job.

Make sure your motor’s speed and torque fit your project. Use gearboxes if you need more torque at slow speeds.

Pick the right motor type for your project. Brushless DC motors are good for saving energy and need less fixing. Servo motors are best if you want very exact control.

Think about where your motor will be used. Keep it safe from heat, water, dust, and shaking. This helps your motor last longer.

Choose a motor with the right voltage and power. Take care of your motor often to help it work well for a long time.

Torque & Load

Calculating Torque

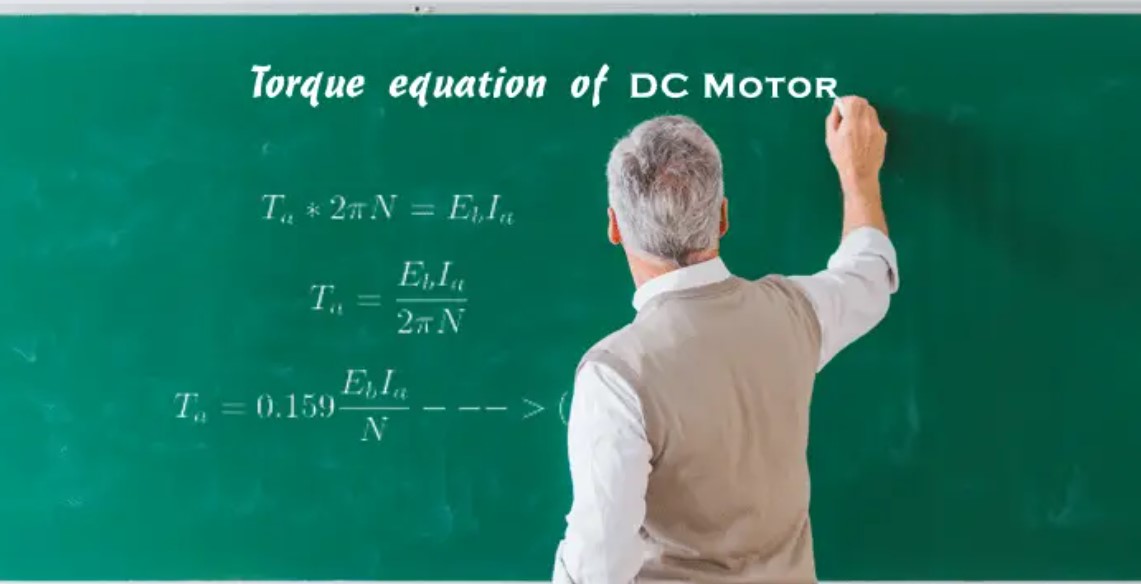

You need to figure out the required torque before you pick a motor. This step is not just about guessing. It is about using the right formulas and making sure your motor can handle the job. Here is a simple way to calculate the required torque for your project:

Find the force. Use the formula: Force = mass × acceleration. For example, if you want to lift a 1 kg object, the force is 1 kg × 9.8 m/s² = 9.8 N.

Measure the radius. This is the distance from the center of the motor shaft to where the force is applied.

Calculate the torque. Use: Torque = Force × Radius. If your radius is 0.01 m, then Torque = 9.8 N × 0.01 m = 0.098 Nm.

Add acceleration torque. If your project needs to speed up quickly, include the torque needed for acceleration.

Apply a safety factor. Multiply your total by a safety factor (usually 1.5 to 2) to make sure your motor can handle unexpected loads.

Tip: Always choose a motor with a rated torque higher than your calculated required torque. This helps your motor last longer and work safely.

Here is a table to help you remember the steps:

Torque Component | Description and Calculation Approach |

|---|---|

Load Torque | Calculated by multiplying the applied force by the distance from pivot (T = F × r). |

Acceleration Torque | Determined based on the inertia of the system and the required acceleration. |

Required Torque | Sum of load torque and acceleration torque, then multiplied by a safety factor to ensure reliability under varying conditions. |

You should also know that torque is proportional to the square of the rotor radius. If you use a larger rotor, you can get more torque. This is important when you compare different motor types for your project.

Load Profile

The load profile tells you how your motor will work during the whole cycle, not just at one moment. You need to look at all the forces, speeds, and changes that happen while your motor runs. If you skip this step, you risk picking a motor that overheats or wears out too fast.

Think about peak loads. Sometimes your project will need more torque for a short time. Your motor must handle these peaks without damage.

Check the duty cycle. This means how long your motor runs versus how long it rests. Motors that run all the time need to handle more heat.

Look at the type of load. Radial loads (sideways forces) and axial loads (forces along the shaft) affect which bearings you need. Ball bearings work better for high radial loads and last longer.

Match inertia. If your motor and load have very different inertia, your system may respond slowly or shake. Try to keep the inertia ratio close, or use gears to help.

If you do not define your load profile, you might choose a motor that is too small or too big. This can cause overheating, wasted energy, or even motor failure. Always match your motor to your load characteristics and application requirements.

RPM Needs

You also need to know how fast your motor should spin. The required RPM depends on your project. If you need more torque, you often get less speed, and if you want more speed, you get less torque. This is a basic rule for DC motors.

High gear ratios give you more torque but lower RPM.

Low gear ratios give you more RPM but less torque.

For example, a direct-drive motor might spin at 3000 RPM but have low torque. Add a gearbox, and you can get 60 RPM with much higher torque.

Note: Always check the torque-speed curve for your motor. As you increase the load (torque), the RPM drops. If you need high torque at low speed, use a geared motor. This keeps your motor safe and efficient.

When you select a motor, make sure the rated speed and required torque fit your needs. If you run a high-speed motor at low RPM with high torque and no gearing, you risk overheating and damaging the motor. Using the right motor types and gearboxes helps you get the best performance for your project.

DC Electric Motor High Torque

High Torque Motor Types

When you look for a dc electric motor high torque, you will find several motor types. Each one has its own strengths and weaknesses. Picking the right high torque motor depends on what your project needs. Let’s break down the most common motor types you will see in high torque applications.

Here is a table to help you compare the main motor types:

Motor Type | Torque Output | Efficiency | Control & Maintenance | Best Use Cases |

|---|---|---|---|---|

Series Wound DC Motor | Very high starting torque, drops at high speed | Lower (brush losses) | Needs regular brush maintenance | Heavy lifting, cranes, winches |

Permanent Magnet DC Motor | High torque at low speed, steady output | Good (no field power) | Easy speed control, magnets can fade | Robotics, small vehicles, conveyor belts |

Brushless DC (BLDC) Motor | High torque across wide speed range, steady at high RPM | Very high (85-90%) | No brushes, low maintenance | Drones, e-bikes, precision tools, automation |

Servo Motor | High torque with precise position control | High | Built-in feedback, needs controller | Robotics arms, CNC machines, camera gimbals |

Stepper Motor | Good torque at low speed, moves in steps | Moderate | Simple open-loop control | 3D printers, plotters, precise positioning |

You will notice that series wound motors give you a lot of torque at startup. This makes them great for jobs where you need to move heavy things from a stop. Permanent magnet DC motors also deliver strong torque at low speeds. They are easy to control and work well for steady, simple tasks.

Brushless DC motors stand out because they give you high torque and keep it steady, even when you speed up. They do not have brushes, so you do not need to worry about replacing parts as often. These motors also run cooler and last longer. If you want a high torque motor that is efficient and needs little care, brushless DC is a smart choice.

Servo and stepper motors are special. They combine a dc electric motor high torque with extra control features. Servo motors use feedback to hold a position, even if the load changes. Stepper motors move in small steps, which helps you get precise movements. Both are popular in robotics and machines that need exact control.

Tip: If you want a high torque motor for robotics, look at brushless DC, servo, or geared brushed DC motors. They give you the power and control you need for smooth, strong movement.

Gearbox Use

Sometimes, you need more torque than a single motor can give. This is where a gearbox comes in. A gearbox connects to your dc electric motor high torque and changes how it works. It lowers the speed but boosts the torque. This is perfect for high torque motor setups that need to lift, push, or move heavy things slowly.

Here are some common situations where you should use a gearbox:

Robotics: You want your robot to lift heavy objects or move slowly and smoothly. A high gear ratio, like 10:1, helps you get the torque you need.

RC Cars: If you want your car to climb hills or push things, a gearbox gives you extra torque, even if it means going slower.

Industrial Machines: Machines like conveyor belts or presses need steady, strong force. Gearboxes with ratios from 15:1 to 100:1 help deliver that power.

Precision Tools: Sometimes, you need exact control. A gearbox can help you get just the right amount of torque for careful work.

Note: When you use a gearbox, you trade speed for torque. The higher the gear ratio, the more torque you get, but your motor spins slower.

Gearboxes do more than just boost torque. They also protect your motor from overload. By matching the torque to your load, you keep your high torque motor safe and running longer. But gearboxes are not perfect. They add friction and make your system a bit less efficient. Each gear stage loses a little energy as heat. You also need to take care of your gearbox. Lubricate it and check for wear to keep everything running smoothly.

Gearboxes let your dc electric motor high torque work at its best speed. This keeps the motor cool and helps it last longer.

The total efficiency of your system depends on both the motor and the gearbox. If your gearbox is not efficient, you lose more power.

Different gear types, like spur, planetary, or worm gears, have their own pros and cons. Some need more care and maintenance than others.

If you want a high torque motor system that lasts, pick the right gearbox and keep it in good shape. Always think about how much torque you need, how fast you want to go, and how much care you can give your setup.

Environment

Temperature & Humidity

You might not think about it, but where you use your motor matters a lot. High temperatures can really hurt your motor’s performance. When things get hot, the wires inside the motor build up more resistance. This makes the motor work harder and lose power. If the temperature gets too high, the magnets inside can even lose their strength forever. That means your motor will never work as well again. In fact, at high temperatures, your motor might only give you about 70% of its normal power.

Humidity is another big problem. Moisture can sneak inside and break down the insulation on the wires. This can cause short circuits or even make the metal parts rust. When water gets trapped, it also makes it harder for the motor to cool down. All these things can make your motor less reliable and shorten its life.

Tip: Always look for motors with good sealing and moisture protection if you expect heat or humidity. This helps your motor last longer and keeps it running safely.

Dust & Chemicals

Dust and chemicals can be just as tough on your motor as heat and water. Dust can get inside and clog up moving parts. Chemicals can eat away at the metal or plastic. Both can cause your motor to fail early.

Here are some protection ratings you should know:

Explosion-proof motors keep dangerous gases or dust from causing fires inside the motor.

Hazardous Location motors meet strict safety codes for places with risky dust or gases.

Washdown motors work well in wet or chemical-heavy spots, but not in places with explosive dust.

NEMA and IP ratings tell you how well a motor keeps out dust and water. For example, NEMA TE motors match IP54, and washdown motors match IP55.

Make sure you pick a motor with the right rating for your environment. This keeps your project safe and your motor running strong.

Vibration

Vibration can shake your motor apart if you ignore it. You want your motor to run smoothly and quietly. Here are some best practices to help:

Best Practice | Why It Helps |

|---|---|

Tighten parts often | Stops loose pieces from shaking and causing damage |

Replace worn parts | Keeps things running smooth and quiet |

Balance moving parts | Reduces shaking and noise |

Use rubber mounts | Absorbs vibration and protects the motor |

Test for vibration early | Finds problems before they get worse |

If you follow these steps, your motor will last longer and work better, even in tough spots.

Specs & Power

Voltage Match

Getting the voltage right is one of the most important steps when you choose a high torque DC electric motor. If you use the wrong voltage, your motor can overheat, lose power, or even break down early. Here’s what you need to check:

The motor’s rated voltage should match your power supply.

If you use a lower voltage, your motor will run slower and give less torque.

If you use a higher voltage, your motor will spin faster and pull more current, but this can damage the motor unless you limit the current.

Always make sure your power supply can handle the stall current, which is the highest current the motor will draw when it starts or gets stuck.

Use fuses or circuit breakers to protect your motor from heavy loads.

Here’s a quick table to help you understand the basics:

Parameter | What It Means |

|---|---|

Rated Voltage | The voltage your motor is designed for. |

Lower Voltage | Less speed and torque. |

Higher Voltage | More speed and torque, but risk of damage if not controlled. |

Stall Current | Maximum current at zero speed; your power supply must handle this safely. |

Current Limiting | Protects your motor from drawing too much current and getting damaged. |

If you see your motor getting hot or not reaching full speed, check for voltage mismatch. Even a small difference can cause big problems, like overheating or loss of torque.

Power Output

You need to know how much power your project needs. Power output depends on both torque and speed. You can use this simple formula:

Power (W) = Torque (Nm) × RPM × 0.1047

This formula helps you figure out if your motor can handle the job. Always add a safety margin—pick a motor that gives you about 20% more power than you think you need. This keeps your system running smoothly, even if the load changes.

If you want to check your math, here’s another way to look at it:

A motor that gives 0.75 kW (750 W) at 2000 RPM delivers about 3.6 Nm of torque. When you look at motor specifications, make sure the numbers match your project’s needs.

Efficiency

You want your motor to use as little energy as possible while still doing the job. High performance motors, like brushless DC motors, can reach efficiency ratings up to 91.9%. DC geared motors can also be very efficient, sometimes up to 85%. Choosing an efficient motor means you save energy, reduce heat, and your motor lasts longer.

Here’s a quick look at some efficient motor types:

Motor Type | Typical Efficiency (%) |

|---|---|

Brushless DC (BLDC) | 85 – 91.9 |

DC Geared Motor | Up to 85 |

If you want a motor that runs cool, lasts long, and keeps your energy bills low, look for high efficiency in the motor specifications. Efficient motors also need less maintenance and make less noise.

Tip: Always check the efficiency rating before you buy. A more efficient motor may cost a bit more, but it pays off in the long run.

Installation

Size & Mounting

When you install a high torque DC electric motor, space can be tight. In many factories, you might not have much room on the floor. Sometimes, you need to mount the motor vertically to save space. This can make things tricky, like keeping the shaft lined up and making sure oil spreads out right for lubrication. If you don’t manage these details, your motor might wear out faster.

Here are some common space challenges you might face:

Not enough horizontal space, so you need to mount the motor vertically.

Vertical mounting can make it harder to keep the shaft straight.

Lubrication gets tricky when gravity pulls oil away from where it’s needed.

More weight on the bearings in vertical setups can shorten the motor’s life.

Flange and face mounting help save space and work well for high-torque jobs.

Tip: Always mount your motor on a flat, stable surface. Use bolts that fit the motor’s size and weight. Make sure everything is lined up right. Even a small misalignment can cause friction and waste energy.

Maintenance

If you want your motor to last, you need to take care of it. Regular checks help you spot problems early. Here’s a simple checklist you can follow:

Inspect the motor for wear, damage, or strange noises.

Check brushes, commutators, and bearings every few months.

Clean dust and dirt from the motor and vents.

Lubricate moving parts as the manufacturer suggests.

Keep a log of all inspections and repairs.

Train anyone who works on the motor to spot early signs of trouble.

Use special tools like vibration testers or thermal cameras to catch problems before they get big.

Keeping up with these steps helps your motor run smoothly and prevents sudden breakdowns.

Lifespan

A well-installed and well-maintained high torque DC motor can last a long time. For example, brushless DC motors often run for 10,000 hours or more if you follow the manufacturer’s rules. Some motors in big machines, like air compressors, can last up to 50,000 hours. Motors in winches or vacuum cleaners can work for over 10 years with very few failures.

Application | Typical Lifespan | Notes |

|---|---|---|

Brushless DC motors | 10,000+ hours | Needs proper maintenance |

Industrial air compressors | ~50,000 hours | Improved over older designs |

DC motor winches | 10+ years | Outlasts many hydraulic systems |

High-end vacuum cleaners | 10+ years | Very low failure rates |

If you keep your motor clean, cool, and well-aligned, you’ll get the most out of it. Regular care really pays off!

Budget & Sourcing

Cost vs. Performance

When you shop for a high torque DC electric motor, you will see a big range in prices. The cost depends on what you need your motor to do. Here are some things that can change the price:

The type of motor matters. Brushed DC motors cost less up front but need more maintenance. Brushless DC motors cost more at first but last longer and save energy.

Materials like steel and aluminum affect both strength and price.

Torque output and speed ratings change the cost. Motors with higher torque or special gearboxes cost more.

Custom features, such as different shaft types or mounting options, add to the price.

Add-ons like encoders or special gearboxes make the motor more expensive but help with control and performance.

You might pay more for a brushless DC motor, but you save money over time because it uses less energy and needs less fixing. If you only need a motor for a short project, a brushed DC motor could be enough.

Here’s a quick look at the trade-offs:

Aspect | Brushless DC Motors (BLDC) | Brushed DC Motors |

|---|---|---|

Initial Cost | Higher | Lower |

Efficiency | Higher | Lower |

Maintenance | Low | High |

Service Life | Long | Shorter |

Control Complexity | More | Less |

Supplier Choice

Picking the right supplier is just as important as picking the right motor. You want a company that stands behind its products and delivers on time. Here are some things to look for:

Criteria | What to Look For |

|---|---|

Experience | At least 5 years in business |

Certifications | ISO 9001, CE, or similar |

Quality Control | Good inspection and testing |

Customization | Can make motors to fit your needs |

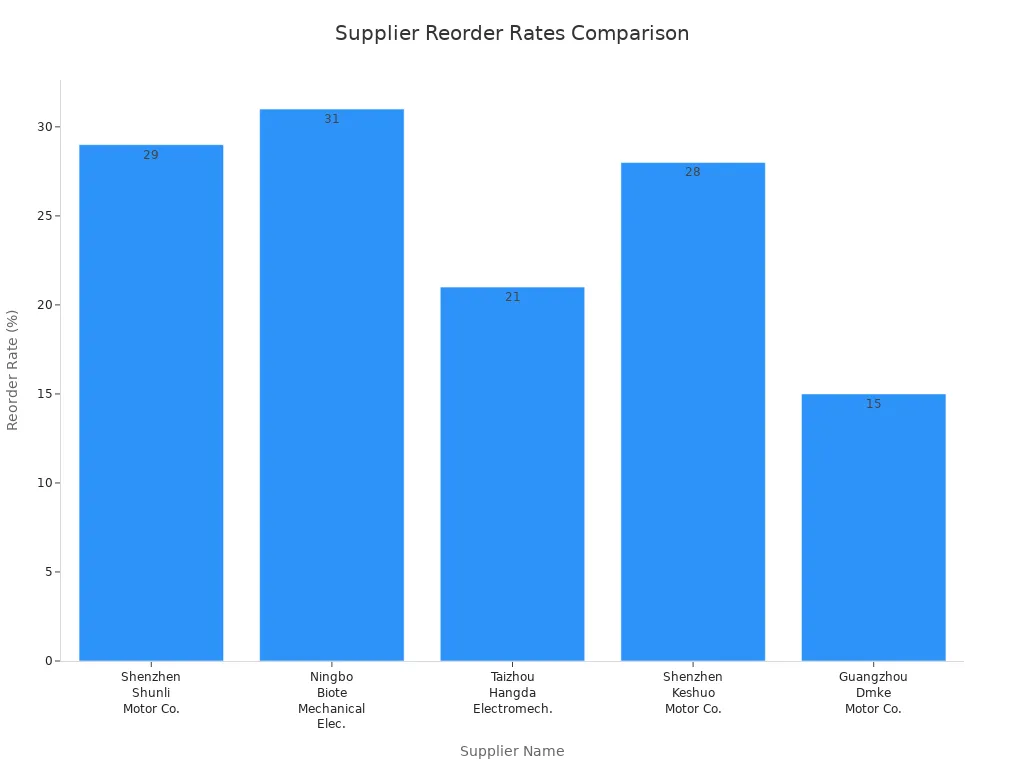

Reorder Rate | 25% or higher shows happy customers |

Fast Response | Answers questions quickly |

Some suppliers have higher reorder rates, which means customers trust them. Take a look at this chart to see how some top suppliers compare:

Tip: Always check reviews and ask for test reports before you buy.

Warranty

A good warranty shows that a supplier trusts their motors. Most top brands offer longer warranties for high torque DC motors. This means they believe their products will last. If a company offers a strong warranty, you can feel more confident about your purchase. Always ask about the warranty terms and what support you get if something goes wrong. A solid warranty can save you money and stress in the long run.

Picking the right high torque DC electric motor is easier with a checklist. You should look at some important things before you buy:

Figure out how much torque you need, then add extra for safety.

Make sure the voltage matches your power supply.

Check if the motor fits your work cycle and where you will use it.

Think about how speed, torque, and size work together.

Choose a good brand and the right motor type for your project.

Get ready to take care of the motor so it lasts longer.

If your project is hard, you can ask motor experts or engineers for help. They can help you match the specs to your project and fix tough design problems.

FAQ

What is the main difference between brushed and brushless DC motors?

Brushed motors use brushes to transfer power. Brushless motors use electronics instead. Brushless motors last longer and need less care. Brushed motors cost less but wear out faster.

How do I know if my motor has enough torque?

Check your project’s needs. Use the torque formula:Torque = Force × Radius

Pick a motor with a higher rated torque than your calculation. This keeps your motor safe and strong.

Can I use a high torque DC motor outdoors?

Yes, you can. Make sure your motor has a good protection rating, like IP54 or higher. Look for motors with sealed cases. This keeps out water and dust.

Why does my motor get hot during use?

Motors heat up if they work too hard or get the wrong voltage. Blocked airflow or too much load can also cause heat. Let your motor cool down and check for problems.

See Also

Choosing The Best 3V DC Motor For Your Project

How To Pick Mini DC Motors For Industrial Use

Guide To Choosing The Perfect Vibrating Motor For Projects

Selecting Battery Powered Motors For Maximum Performance Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry