How to choose the right brushless DC pancake motor for your project

You need to match the brushless dc pancake motor’s torque, speed, efficiency, and size to your project’s needs. Picking the right brushless motors helps your device work well and last longer. Brushless motors have a flat shape, so they fit in small spaces in electronics. Their brushless design means less wear and friction, which helps them last longer. Choosing the right dc motor size, speed, and control system keeps your project working well and steady. Good brushless motors can do fast and strong jobs in tricky places without losing power.

Key Takeaways

Make sure the motor’s torque, speed, size, and efficiency fit your project’s needs. This helps the motor work well and last longer.

Pick pancake motors for small spaces. Their flat shape fits easily and still gives good power and torque.

Look at voltage and current ratings closely. This keeps your device safe and makes sure the motor works with your power supply and controller.

Think about where you will use the motor. Choose one with the right protection for dust, water, or tough places.

Compare cost, quality, and suppliers. Find a motor that is reliable, fits your budget, and meets your project’s needs.

Project Requirements

Load & Application

First, you need to know what your project does. Think about the device you want to build. Is it a drone, robot, home appliance, or medical tool? Each type needs different brushless motors. Home appliances need motors that are quiet and save energy. Drones need motors that are light and strong. They also need good speed control. Medical equipment needs motors that are small, light, and quiet.

Tip: Write down what your project does and what you want the motor to do. This helps you choose the best small brushless motors for your project.

Here is a table that shows how different uses change what motors need:

Application Scenario | Key Motor Specification Requirements | Explanation |

|---|---|---|

Home Appliances | Low noise, energy efficiency, moderate torque and speed | Motors in fans, refrigerators, and air conditioners need to be quiet and save energy. This makes people comfortable and lowers costs. |

Drones | High power-to-weight ratio, high torque, efficient electronic commutation | Motors must be light and strong for stable flight and longer battery life. They need good speed control for easy movement. |

Automotive | Long life, quiet operation, precise speed and torque control, high torque density | Motors in cars need to last long, be quiet, and have good control for safety and comfort. |

Medical Equipment | Wide speed range, low noise, small size, light weight | Motors in medical tools must be quiet and work well at many speeds. They need to fit in small spaces. |

Precision Devices | High torque at low speeds, compact size, minimal volume and weight | Hard drives and direct drive systems use pancake motors for strong force in small spaces. |

Small brushless motors last a long time and need little care. You can use them in robotic arms, exoskeletons, and mobile robots. These places need motors that are small and light.

Home appliances use brushless motors to be quiet and adjust power.

Cars need motors that last long and are easy to control.

Precision devices use brushless dc pancake motors for strong force in tight spaces.

Drones use small brushless motors for steady flight and saving battery.

Medical equipment needs motors with many speeds and low noise.

Speed & Torque

You need to know how fast and strong your motor should be. Speed is how quickly the motor turns. Torque is how much force it gives. Robots may need motors that spin fast and give strong force. Small brushless motors come in many sizes and strengths. The right brushless dc pancake motor gives you a good mix of speed and torque.

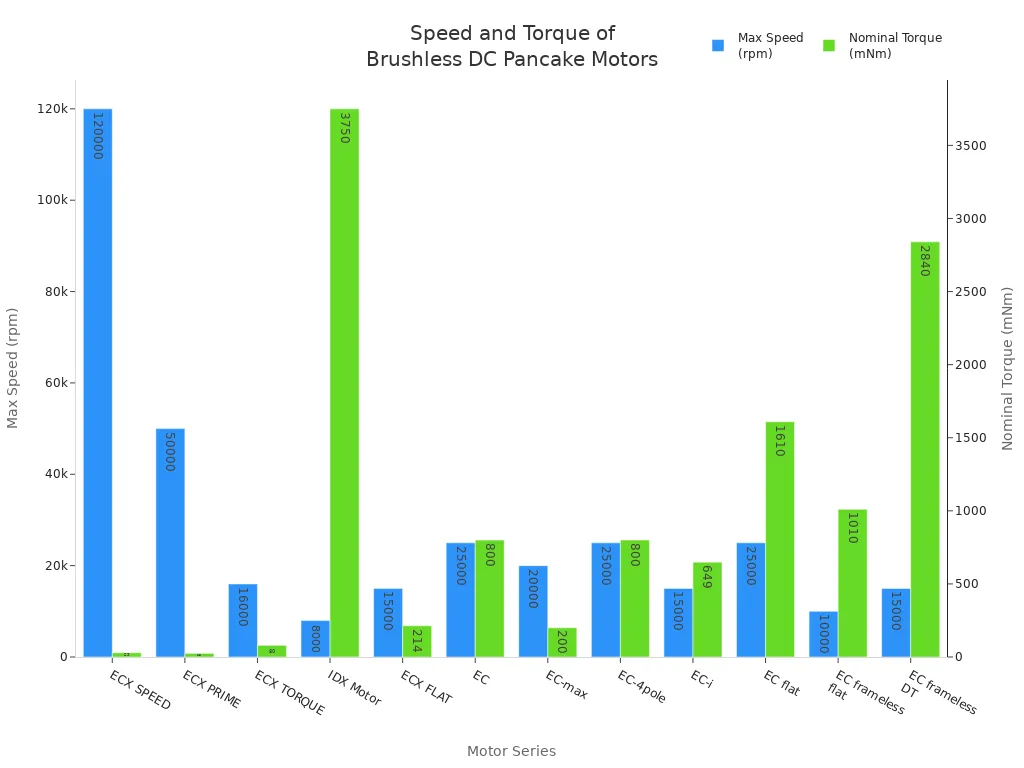

Here is a table that shows speed and torque for different motor series:

Motor Series | Diameter Range (mm) | Nominal Torque Range (mNm) | Max Speed Range (rpm) |

|---|---|---|---|

ECX SPEED | 4 ... 22 | up to 29 | up to 120,000 |

ECX PRIME | 6 ... 16 | up to 25 | up to 50,000 |

ECX TORQUE | 22 | up to 80 | up to 16,000 |

IDX Motor | 56 ... 70 | up to 3750 | up to 8,000 |

ECX FLAT | 22 ... 42 | up to 214 | up to 15,000 |

EC | 22 ... 60 | up to 800 | up to 25,000 |

EC-max | 16 ... 40 | up to 200 | up to 20,000 |

EC-4pole | 22 ... 32 | up to 800 | up to 25,000 |

EC-i | 30 ... 52 | up to 649 | up to 15,000 |

EC flat | 9.2 ... 90 | up to 1610 | up to 25,000 |

EC frameless flat | 43 ... 90 | up to 1010 | up to 10,000 |

EC frameless DT | 42 ... 90 | up to 2840 | up to 15,000 |

Check how often your motor will run. If it runs all the time, pick a brushless motor that can handle it. If it runs sometimes, you can use a smaller motor.

Space & Environment

Space is a big problem for many projects. Most devices have little room for motors. Pancake motors help because they are flat and small. You can put a brushless dc pancake motor in tight spots. You still get good power and force. Their design uses a printed armature on a disc. This makes them slimmer than regular motors. It helps you build smaller and lighter devices.

Note: Pancake motors are great for gimbals in drones and UAVs. They give strong force, smooth movement, and are light. You can use them in direct drive systems and precision devices. Every millimeter matters in these places.

Here is a table that shows why pancake motors are good for small spaces:

Reason / Feature | Explanation |

|---|---|

Compact, flat design | Pancake motors are flat and light, so they fit in small spaces. |

High torque and efficiency | They give strong force and work well even though they are small. |

High torque-to-weight ratio | They are made to give lots of force for their weight. This is important when space and weight matter. |

Direct-drive simplicity | Brushless motors can connect straight to loads. This makes things simpler. |

Ease of integration | Hollow shafts let you run cables and mount them easily. |

Customization options | You can get them in different sizes and shapes for your needs. |

Long lifespan and reliability | Brushless motors last long and need less fixing. |

Suitability for battery-powered systems | They work well with batteries and keep devices light. |

Application examples | Used in robotic arms, exoskeletons, OEMs, and mobile AGVs where space and weight are important. |

Think about where your motor will be used. Will it face dust, water, or very hot or cold places? Many brushless motors have special ratings to protect them. Some are dust-proof, waterproof, or made for clean rooms. Here is a table that shows common protection types:

Environmental Protection Type | Description | Typical IP Rating Range |

|---|---|---|

Dust-proof | Stops dust from getting in with seals | IP6x |

Drip-proof | Stops drops of liquid or particles from getting inside | IPx1 to IPx9 |

Waterproof | Keeps water out, from drops to full immersion | IPx1 to IPx8 |

Open Frame / Frameless | Has little or no casing | N/A |

Totally Enclosed | No air gets in; types include TEFC and TENV | N/A |

Clean Room Use | Rated for tiny particles in the air | Various standards |

Cryogenic Use | Works in very cold places (like 20 K and below) | N/A |

Explosion-proof | Can handle explosions inside and keeps outside safe | UL governed ratings |

Radiation-hardened | Made to stand up to strong gamma radiation | Expressed in RADs |

Vacuum Use | Built for low vapor pressure and vacuum | N/A |

Some brushless motors, like Sensata's DII-15-60, work in very hot places up to 205°C and high pressure. Frameless small brushless motors can be built into machines for extra protection. This helps against moisture or tough conditions. Always check the motor’s rating before you pick one.

Brushless DC Pancake Motor Specs

Voltage & Current

You should look at voltage and current before picking a brushless dc pancake motor. Voltage shows how fast the motor spins. Current tells you how much force the motor gives. Most brushless motors in electronics use 8 to 36 volts. The usual voltage is about 24 volts. Here is a table with common values:

Specification | Value |

|---|---|

Nominal Voltage (V) | 24 |

Input Voltage Range (V) | 8 to 36 |

Nominal Current (A) | 7.45 |

Nominal Power (W) | 200 |

Motor Type | Brushless DC Pancake Motor |

You need to match the motor voltage with your battery or power supply. For battery-powered devices, voltage and current are very important. More voltage means faster speed. More current means more force. If you choose a motor with too much current, it can get hot and waste energy. Brushless motors help save battery because they use less power and make less heat.

Tip: Always check voltage and current for your motor and controller. This keeps your device safe and stops damage.

Brushless motors change how much current they use depending on the load. If your device needs less force, the motor uses less current. This saves energy and makes your system work better. For example, in fans or pumps, the controller changes speed and force to fit the load. You do not need extra gears or belts, so your design is simpler.

Power & Efficiency

Power is how much work the motor does. Efficiency is how well the motor turns electricity into movement. Brushless motors are very good at saving energy. In robots, these motors can be 85% to 90% efficient. Some special motors can reach up to 96%. Here is a table with efficiency rates:

Feature | Efficiency Range |

|---|---|

Efficiency Rate of Brushless DC Motors in Industrial Robotics | 85% - 90% |

Maximum Output Efficiency for Brushless Motors in Industrial Equipment | Up to 96% |

Brushless motors use strong magnets and smart controllers. This design helps stop wasted energy and heat. You get more work from the same electricity. If you use brushless motors in battery devices, they run longer and stay cooler. This helps your device last more years.

Brushless motors are better than regular AC motors for saving energy. You get 1-2% more efficiency at full power and 10-15% more at lower power.

Smart designs like more pole pairs and pancake shapes give more power.

Brushless motors keep high efficiency even when power goes up. The rotor does not get very hot, so cooling is easier.

Small brushless motors can give strong force and power in tight spaces.

New magnet materials and better controllers make brushless motors work even better.

Note: If you want your device to save energy and last longer, pick brushless motors with high efficiency.

Torque & Rotor Size

Torque is the force that turns the motor shaft. Rotor size, especially diameter, changes how much torque you get. In brushless motors, bigger rotors give more torque. If you double the rotor diameter, you get four times more torque. This happens because the force works farther from the center, giving more leverage.

Torque goes up with motor length but even more with rotor diameter.

Bigger rotors give more leverage and higher force.

Pancake motors use thin rings for copper and magnets to boost force.

More pole pairs and stronger magnets also increase torque.

You can find stall torque in the motor specs.

Brushless motors let you balance speed and force for your project. If you need strong force for heavy loads or careful control, pick a motor with a bigger rotor. If you need high speed, you might lose some force. In jobs like robotics or medical tools, you need to balance force and speed. More force means slower speed. More speed means less force.

Tip: Use torque-speed graphs to match the motor to your needs. This helps you choose the right brushless motors for steady and accurate work.

Here is a simple list to help you remember the trade-offs:

More force = slower speed

More speed = less force

Bigger rotor = more force

Higher current = more force, but watch for heat

Use gears if you need more force without losing speed

Brushless motors give you many choices for force and speed. You can pick the right size and shape for your project. Always check the specs and think about your load and speed needs.

Small Brushless Motors: Application Fit

Sizing & Selection

Pick a small brushless motor that fits your project. First, check how much space you have. These motors are flat and fit in tight places. You see them in floppy disk drives and hard drives. They also work in dc brushless fans. Small brushless motors go inside small electronics and give steady power.

Think about what you want the motor to do. If you need low torque and careful control, these motors are good. You find them in computer fans and CD/DVD players. Their shape saves space and energy. Also, look at how fast and strong the motor needs to be. Choose a brushless motor that matches your speed and force needs.

Tip: Write down your device’s size and power needs before picking a motor.

Controller Compatibility

Check if your controller works with small brushless motors. The electronic speed controller (ESC) needs three wires for the motor. The ESC voltage should match the motor’s power supply. The current rating must be higher than the motor’s max draw. This keeps things safe. The motor’s KV rating changes how fast the ESC switches. Sensored ESCs use sensors to know rotor position. Sensorless ESCs guess position using back-EMF. Pick the right ESC for your motor.

ESCs for brushless motors have three wires.

Sensored ESCs work with motors that have sensors.

Sensorless ESCs fit motors without sensors but may not work well at slow speeds.

ESCs use PWM to control speed.

Advanced controllers help with torque, speed, and position. They protect the motor from getting too hot or overloaded.

Controllers can use Modbus and CANopen protocols. This lets you connect your brushless motors to other devices for remote checks.

Cost & Availability

Think about price and where to buy small brushless motors. High-performance brushless motors cost more than regular ones. They use rare earth materials to last longer, but this can change prices. Motors for tough places need special parts like sealed bearings. Strong materials make them last longer but cost more.

Aspect | Explanation |

|---|---|

Cost Premium | High-performance small brushless motors cost more than regular ones. |

Advanced Materials | Rare earth elements make motors last longer but raise prices. |

Durability | Motors must handle shocks, vibration, and heat. |

Long-term Benefits | You save energy and need less fixing over time. |

Innovations | Modular designs help lower costs and keep quality high. |

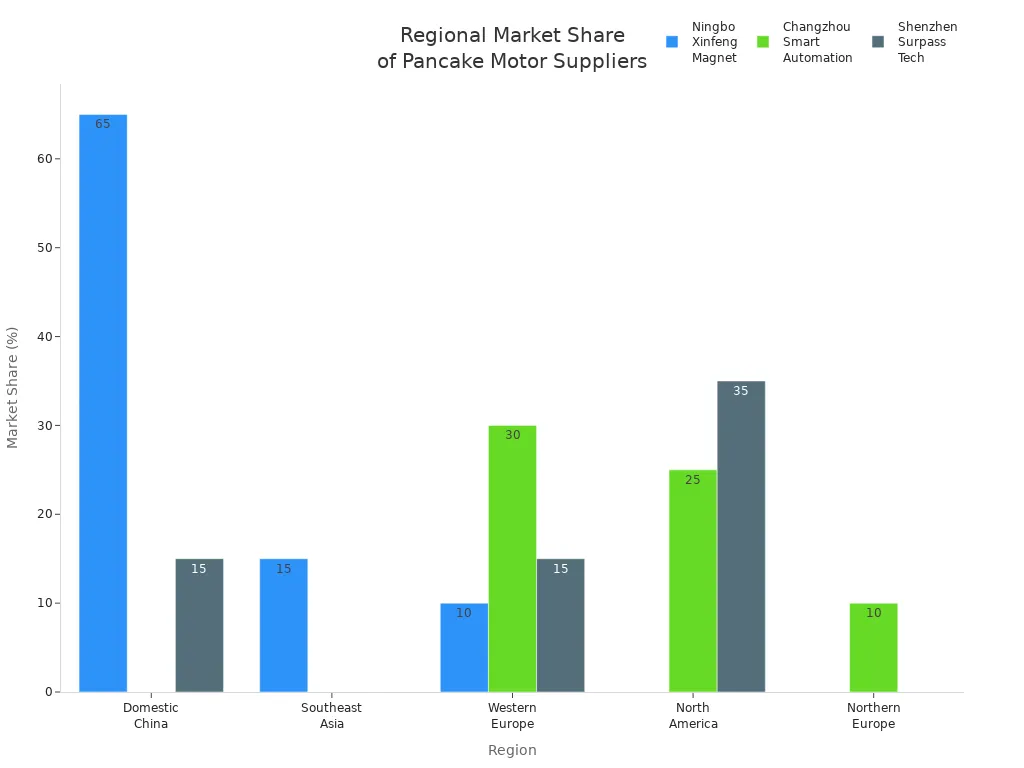

Asia-Pacific, especially China, has many small brushless motor suppliers. China exports to Europe and North America. There are over 1200 companies to choose from. The chart below shows market share by region.

Supplier Name | Country | Main Regional Markets | Market Share by Region (%) | Revenue Range (USD) | Response Rate (%) |

|---|---|---|---|---|---|

Ningbo Xinfeng Magnet Industry Co., Ltd. | China | Domestic China, Southeast Asia, Western Europe | 65%, 15%, 10% | 10M - 50M | 47.6 |

Changzhou Smart Automation Motor Manufacturing Co., Ltd. | China | Western Europe, North America, Northern Europe | 30%, 25%, 10% | 2.5M - 5M | 78.7 |

Shenzhen Surpass Tech Co., Ltd. | China | North America, Western Europe, Domestic China | 35%, 15%, 15% | 2.5M - 5M | 57.7 |

You can buy small brushless motors for many things, like dc brushless fans and electronics. Always balance price, durability, and supplier choices to get the best motor for your project.

Picking the right brushless DC pancake motor means matching its specs to your project. You should look at every part before you choose. Here is a checklist to help you:

Make sure the voltage is right.

Know how much torque and load you need.

Pick the speed (RPM) that fits your project.

Check how long the motor will run.

See if the size and mounting work for your space.

Look at the power ratings.

Think about the load type.

Pick a motor with high efficiency.

Make sure it is tough and can handle the environment.

Check if your controller works with the motor.

Think about price and if you can get the motor easily.

If your project is hard, talk to motor suppliers or experts. They can help you and stop you from making mistakes.

FAQ

What makes a pancake motor different from a regular motor?

Pancake motors have a flat, disc-like shape. You can fit them into tight spaces where regular motors will not work. They also give you high torque for their size.

How do I know if my controller works with a brushless DC pancake motor?

Check your controller’s voltage and current ratings. Make sure they match your motor’s needs. Most brushless motors need a three-phase controller. You should also check if your motor uses sensors.

Can I use a brushless pancake motor in wet or dusty places?

Many pancake motors have protection ratings like IP65 or IP67. You should look for these ratings if you need to use your motor in tough environments.

Why do I need to match torque and speed to my project?

If you pick the wrong torque or speed, your device may not work well. You could get overheating, wasted energy, or poor performance. Always check your project’s needs before you choose a motor.

See Also

Choosing The Best Vibrating Motor For Your Project Needs

How To Pick The Ideal 3 Volt DC Motor For Projects

Finding The Perfect Mini DC Motors For Industrial Use

Tips For Choosing Planetary Gear Motors For Accurate Screwdrivers

Why Investing In Mini Brushless Motors Benefits Precision Tasks

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry