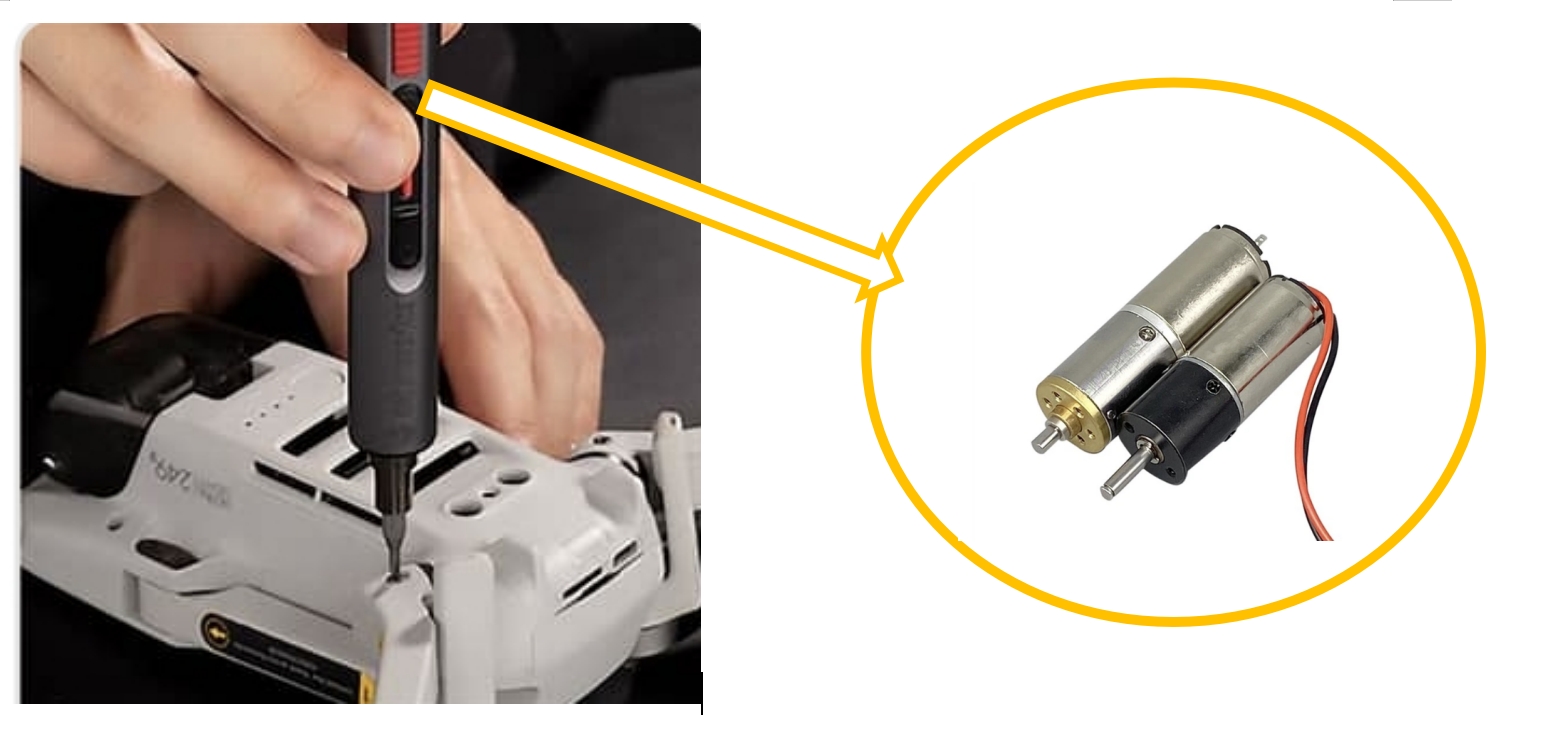

How to choose a planetary gear motor for precise screwdriver

A planetary gear motor is great for accurate screwdrivers. It gives strong power, works well, and fits small spaces. These motors help with problems like staying accurate under pressure and working in tight spots. For example, planetary gears can give 30 to 50% more power than spur gears. A three-stage gear system can boost power up to 125 times, making it very reliable for tough jobs. Small designs with DC motors make them perfect for machines needing space-saving and accuracy.

Key Takeaways

Planetary gear motors give strong power to tighten screws properly.

Their small size helps them fit in tight spots easily.

Picking the right power and speed improves accuracy and tool use.

Strong materials make motors last longer, even in tough jobs.

Saving energy is important; efficient motors lower costs and help nature.

Benefits of Using a Planetary Gear Motor in Precision Screwdrivers

Strong torque for accurate fastening

Planetary gears give strong torque, which helps tighten screws correctly. This system ensures screws are not too tight or too loose. Torque checks are important to get this balance right. The table below shows why torque matters:

Test Result Type | Meaning |

|---|---|

Pass/Fail Results | Shows if torque meets the needed level, avoiding poor performance. |

Over-Torque Results | Warns about too much torque, which can break parts or cause safety issues. |

Under-Torque Results | Points out weak tightening, which might lead to parts coming apart under pressure. |

Planetary gears help control torque, lowering the chance of damage or failure in screwdrivers.

Small design for tight spaces

Planetary gears are small, making them great for tight screwdriver spaces. Unlike other gears, they use a straight shaft and round casing to save space. Here are some design benefits:

They create lots of torque for their size.

Their small size fits well in space-saving screwdriver designs.

This design lets you work in small areas without losing power or accuracy.

Reliable and efficient for tough jobs

Planetary gear motors are great for hard tasks because they are reliable and efficient. They share the load across many gears, which reduces wear. This design keeps them working well even with heavy use. They save energy while giving the torque needed for tough jobs.

Choosing planetary gears gives you a strong and long-lasting option for precise screwdrivers. They are built to handle tough tasks and last a long time.

Key Factors to Consider When Picking a Planetary Gear Motor

Torque needs for screwdriver tasks

Knowing torque needs is key when picking a planetary gear motor. Torque decides how tight screws are, avoiding loose or over-tightened screws. Planetary gears give steady torque, making them great for precise jobs.

Check these torque details:

Aspect | Specification |

|---|---|

Target Torque | |

Clutch Control | +/- 7% |

Current Control | +/- 5% |

Transducerized | +/- 3% |

Multiple Torque Capability | Up to 100 with Kolver’s K-Ducer line |

These points help match the gear motor to your screwdriver. Regular torque checks keep performance good and prevent fastening mistakes.

Speed and accuracy for exact work

Speed and accuracy are important for precise results. Planetary gears control these well, making them good for tough tasks. Torque tests help keep screws tight without errors.

Good accuracy also makes tools last longer and need less fixing. Picking the right speed and accuracy boosts work quality and tool reliability.

Size and fit for screwdriver design

The motor size should match your screwdriver's design. Small planetary gears work well in tight spaces. Check the motion details like speed, torque, and cycle rate for a good fit.

Gear ratios matter too. Single-stage planetary gears usually range from 3:1 to 10:1. Ratios between 4:1 and 8:1 balance size and power best. Adjusting for heavy use can make them last longer. By checking these things, you can find a motor that fits your screwdriver perfectly.

Durability and material quality for long-term use

When picking a planetary gear motor, durability is very important. The materials used in the gears affect how long the motor lasts. Strong materials like hardened steel or tough alloys resist damage better. This makes the motor work well even in tough conditions.

Certifications help check the quality and durability of the motor.

You should also check if the motor can handle heavy torque for a long time. Torque tests show if the gears stay strong under pressure. A good motor spreads torque evenly, lowering the chance of breaking. This makes it a reliable choice for precise screwdrivers.

Energy efficiency and power consumption considerations

Energy efficiency is key when choosing a planetary gear motor. Efficient motors waste less energy and work better. Good planetary gears turn most electrical energy into mechanical energy. This lowers costs over time. For example, 12V DC motors are more efficient than AC motors, making them great for precise tasks.

Think about how the motor works with different torque levels. Motors are most efficient at certain torque points. Running the motor near these points saves energy. Torque tests can help find the best settings for efficiency.

Performance Factor | What It Means |

|---|---|

Gearbox Efficiency | Reduces energy waste and helps the motor last longer. |

Energy Conversion | 12V DC motors turn more electricity into power than AC motors. |

Operational Costs | Efficient motors cost less to run over time, even if they cost more upfront. |

Load and Efficiency | Motors work best at specific torque levels, saving energy. |

By focusing on energy efficiency, you save power and make the motor last longer. This ensures your screwdriver works well and is better for the environment.

Getting expert advice makes choosing a motor easier and more reliable. Whether for a small tool or a big machine, their help ensures great results.

Exploring the IND-GM1625-500 Planetary Gear Motor

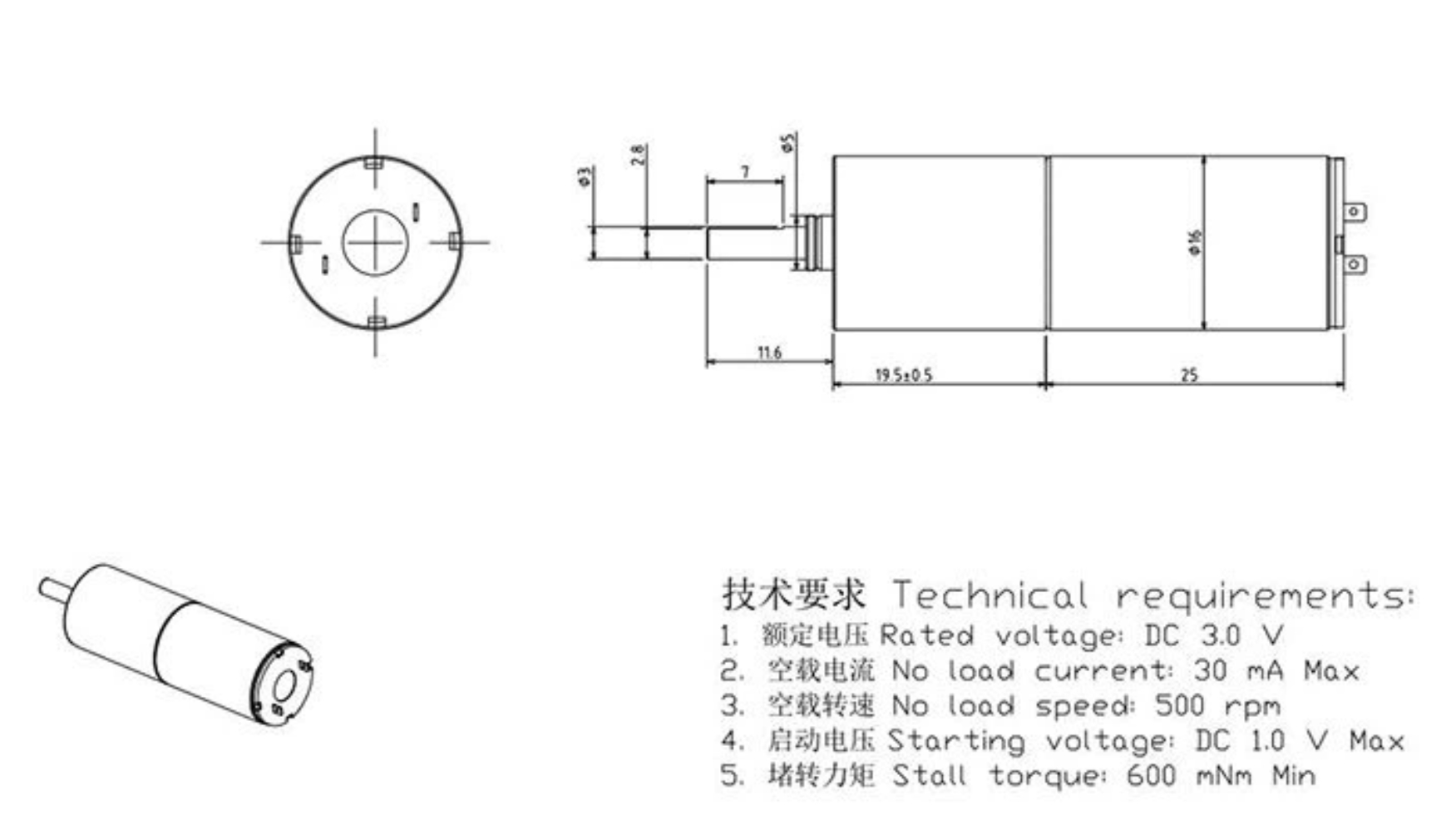

Features and specifications of the IND-GM1625-500

The IND-GM1625-500 planetary gear motor is small but strong. Its 16mm size fits tools like screwdrivers needing compact designs. It runs on 3.0 V DC power and gives 500 rpm speed. This motor reduces speed while increasing torque, making it work efficiently.

It has a tough metal gearbox and gears for better durability. The motor allows flexible movements, including counterclockwise and vertical directions. With a torque range of 0.5-10kgf.cm and an IE 1 efficiency rating, it changes electrical energy into mechanical energy well. It works reliably even in tough conditions, making it great for hard tasks.

Customization options for specific screwdriver needs

The IND-GM1625-500 offers many ways to customize it. You can change things like shaft size, voltage, speed, and torque to fit your needs. Other options include connectors, wires, gears, and encoders.

This flexibility helps match the motor to unique screwdriver designs or tough environments. For example, you can pick a silver gearbox for precision or a black one for extra strength. These choices make sure the motor fits your project perfectly.

Applications and advantages of the IND-GM1625-500

This motor works well in many areas, like smart home devices, car tools, communication gadgets, and medical machines. Its small size and efficient energy use make it great for tight spaces.

Main benefits include:

Increased torque: The design boosts torque, handling tough jobs easily.

Reduced speed: The gears control speed, ideal for precise screwdrivers.

Durable performance: Built to last, it handles heavy use and frequent tasks.

Energy efficiency: It saves energy, cutting costs over time.

Choosing the IND-GM1625-500 gives you a dependable, adjustable, and efficient motor for screwdriver tasks.

To ensure its liability, we could also equip this motor with carbon brushes instead of metal brushes.

FAQ

Why are planetary gear motors good for precise screwdrivers?

Planetary gear motors give strong torque and accuracy in small sizes. They spread the load across gears, lowering wear and boosting precision. This makes them great for tasks needing careful fastening and dependability.

How can you find the right torque for your screwdriver?

Know your screwdriver's torque needs. Test torque to avoid screws being too tight or loose. Match the motor's torque ability to your task for the best results.

Can planetary gear motors handle tough jobs?

Yes, they are made to last. Their design spreads stress across gears, handling heavy loads and frequent use. Regular care keeps them working well for a long time.

Are planetary gear motors energy-saving?

These motors turn most electricity into power, wasting little energy. Running them at their best torque levels saves more energy and cuts costs.

Can planetary gear motors be customized?

Yes, many makers let you customize them. You can change things like shaft size, voltage, speed, and torque. Extra features like connectors and gears can also be adjusted for your project.

See Also

A Comprehensive Guide to 3V Motor Applications and Specs

Five Innovative Devices Utilizing 3V DC Motors Effectively

Brushed Versus Brushless: A Look at 3 Volt Motors

Vibration Motors: Key Applications Across Various Industries Today

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry