Why Brushless DC Motors Are the Top Choice for Compact Spaces

Brushless dc motors are the best choice when space is tight. They give strong performance in a small size. These motors have high power for their size and use energy well. Look at the table below to see why bldc motors are used in small spaces:

Feature | Value/Explanation |

|---|---|

Efficiency | 90–95% |

Torque-to-weight ratio | Higher than other motor types |

Frame sizes | As small as 5 mm, up to 52 mm |

Market share (inner rotor) | Over 60% in 2024 |

Motor applications | Automotive, electronics, robotics, medical devices |

With bldc motors, you get a light design, fast speed, and less wasted power. You can count on these motors to work well, even in small spaces where every bit of room matters. Many people who build robots and electronics use brushless dc motors. They do this because these motors work well and last a long time.

Key Takeaways

Brushless DC motors give strong power and torque. They are small and light. This makes them great for small spaces. Brushless DC motors have fewer moving parts. They last longer than brushed motors. They also need less fixing. You can mount these motors in many ways. This helps them fit in many projects. It saves space and makes them work better. Brushless DC motors run smoothly and quietly. They are very reliable. They are good for wearable devices, robots, medical tools, and portable devices.

Compact Size Advantages

Smaller Size

You need strong drivers in small spaces. Brushless dc motors help with this. They give a lot of power for their weight. These motors also make strong torque in a small size. The inner rotor design puts the rotor inside the stators. This makes the motor lighter and smaller. You can use these motors where space is very tight.

Inner rotor bldc motors are popular because they are small and work well.

These motors run at 2,000 to 10,000 RPM. This speed is good for robots, cars, and machines.

BLDC motors are 85-90% efficient. This is better than brushed motors.

The smallest brushless dc motor is only 5 mm diameter and 1.8 mm thickness. It's weigh just 0.3 grams but still give strong power and quick response.

This table shows you get lots of power and torque from a small motor. When you need strong torque and power in a small space, brushless dc motors are the best choice.

Tip: Using a smaller motor saves room for other parts in your project.

Lightweight Design

You need drivers that are small and light. BLDC motors are lighter than brushed motors. They do not have brushes or commutators. This makes them weigh less and easy to put in.

Frameless bldc motors give more power for their weight.

In drones and robots, lighter motors work better and move smoother.

Some motors use aluminum matrix composites to make the rotor lighter by 40%. Taking out extra rotor core can cut weight by 25% and make power density 57% higher.

Military UAVs and new drones use these light motors for better flight and control. Lighter motors make your drivers work better and easier to use. That is why many engineers pick bldc motors when every gram is important.

Note: Light motors help you meet size and weight rules in robots, medical tools, and electronics.

Brushless DC Motors Performance

Power Density

You want a lot of power in a small space. That is why bldc motors are special. In the last twenty years, engineers made these motors stronger but not bigger. Now, you get over ten times more power density than old motors. This happened because of better magnets like neodymium and smarter designs. You can see this in new drivers like the MC-5000 series. This controller puts control and power in one small box. It fits in tight places, handles high current, and keeps your motor fast.

The MC-5000 controller works with many feedback types. This helps you tune your motor for the best results.

Four-quadrant drive lets you brake and move both ways. This helps you control speed and hold torque.

The small design makes it lighter and smaller. It is great for robots, actuators, and self-driving vehicles.

You get more power and better speed control in less space. This lets you build smaller and lighter machines without losing strength. When you need drivers that work well in small spaces, bldc motors help you win.

Heat Dissipation

You want your motor to stay cool in small spaces. Good heat dissipation keeps your motor safe and working right. Engineers check this by seeing how heat moves from the coil to the outside. They look at thermal resistance, coil temperature, and the highest safe temperature to stop overheating.

Thermal Parameter | What It Means | Why It Matters |

|---|---|---|

Thermal Resistance | How well heat flows out of the motor | Lower values mean better cooling |

Steady-State Coil Temperature | Coil temp during long use | Shows if the motor stays safe |

Maximum Admissible Temperature | Highest safe temp for motor parts | Prevents damage |

Rated Current | Max current for safe operation | Keeps motor from overheating |

Thermal Time Constant | How fast temp changes in the coil | Important for short bursts of speed |

You can see how airflow and cooling change how well the motor works. Engineers use test tools with sensors to check temperature and speed inside and outside the motor. They also try different cooling tricks, like special coatings or radiators, to help heat move out. These steps help you get the best from your drivers, even when there is not much room for big cooling systems.

Tip: Good heat dissipation lets your motor run fast and strong for longer, even in small spaces. This is why bldc motors are used in robots, electronics, and cooling systems.

Reliability in Limited Spaces

Fewer Moving Parts

You want a motor that works well for a long time. This is very important when you do not have much space. Brushless DC motors are special because they have fewer moving parts than brushed motors. There are no brushes or commutators inside these motors. This design takes away the main things that break down. Instead, these motors use electronic switching and ball bearings. These parts help the motor run smooth and quiet.

Motors with fewer moving parts break less often. For example, a factory in Shenzhen used brushless motors. Their monthly failure rate dropped from 4.3 to 0.7. That is an 83% drop. In medical devices, tests show 90% of brushless motors last over 10,000 hours. You can trust these motors to work for many years without stopping.

Aspect | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

Moving Parts | Brushes, commutator | No brushes, no commutator |

Lifespan | 1,000–3,000 hours | 10,000–25,000 hours |

Maintenance | Frequent | Minimal |

Failure Rate | Higher | Much lower |

Tip: Having fewer moving parts means less noise and less heat. This is great for small and sensitive machines.

Low Maintenance

You want a motor that does not need much care. This is important if you put it in a hard-to-reach place. Brushless DC motors help you avoid lots of repairs. You do not have to change brushes every 1,000 to 3,000 hours like with brushed motors. Instead, you can wait up to 8,000 hours or more before service.

This low maintenance is good for places you cannot check often. In robots or medical pumps, you want the motor to keep working without stopping. In factories, using brushless motors has lowered repair costs. Machines also run longer before needing service.

You pick brushless DC motors because they are reliable and last a long time. Their design is perfect for small spaces where you need strong and steady work with less downtime.

Size and Mounting Constraints

Flexible Mounting

When you build things for small spaces, you often have size and mounting problems. Brushless DC motors help because they fit many ways. You can pick from many frame sizes. Some are as small as 12 mm wide. Others are bigger, over 70 mm. This means you can put the motor right where you need it.

Some motors, like the IEC Food Safe series, give you more ways to mount them. They come in many sizes and power levels. Their smooth, steel cases are easy to clean and last a long time. You can mount these motors in different ways. This helps you follow safety and cleaning rules in food or medical places.

How you mount the motor changes how well it works. If you fasten it tight, it shakes less and stays steady. Some motors use cantilevered mounting. This helps cool the motor and stops shaking. When you mount the motor well, it works better and lasts longer.

Design Feature | Benefit for Mounting and Integration |

|---|---|

Frameless motor design | Easy system integration, compact fit |

PCB stator design | Better cooling, sealed for harsh settings |

Direct-drive mounting | Saves space, reduces complexity |

Tip: Flexible mounting helps you put machines together easier. It also helps you build strong machines in small spaces.

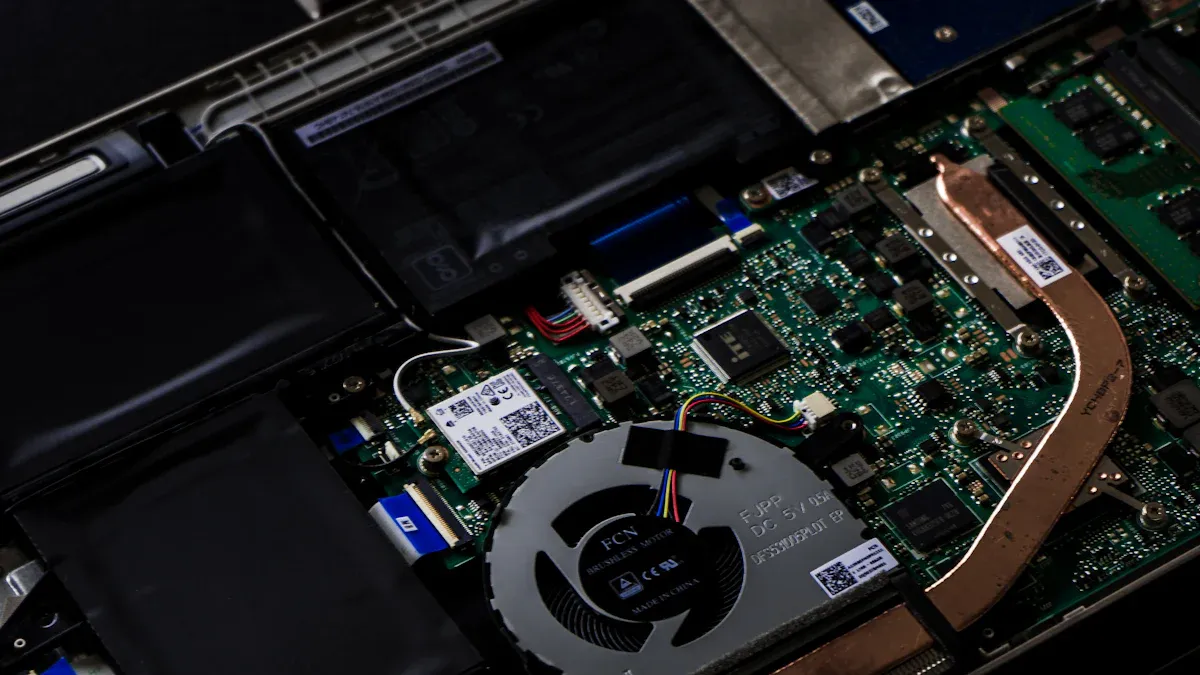

Application Fit

You want your motor to fit just right in your project. Brushless DC motors make this possible. You see these motors in many things. In electronics, they move printer heads and cool computers with small fans. In games and drones, they make things run smooth and quiet.

You also find these motors in small medical tools. They help pumps and surgery tools move just right. These places need small size and motors that always work. In robots, you use brushless DC motors because they are small and easy to control. They help robots move with care and do the same job again and again.

You can use modular designs that mix motors with fans, gears, or controllers. This gives you more power in the same space or saves room without losing strength. When you need to fit in tight spots, brushless DC motors help you build smaller and smarter systems.

You pick brushless DC motors for small spaces because they work really well and save space.

These motors use permanent magnets and smart controls. This gives you strong torque and smooth movement in a small size.

Real-time checks and smart controls help the motor work better. They also make your projects last longer with less noise and fewer mistakes.

With new designs and AI controllers, motors will get even stronger and more efficient for future small devices.

FAQ

Why do brushless DC motors last longer in small spaces?

You get longer life because brushless DC motors have no brushes to wear out. Fewer moving parts mean less friction and less heat. This helps your motor run for years, even in tight spots.

Why should you choose brushless DC motors for portable devices?

You should pick brushless DC motors because they are light and small. These motors give you strong power without adding much weight. Your portable device works better and lasts longer with less maintenance.

Why do brushless DC motors work well in robots and medical tools?

You need motors that fit in small places and run quietly. Brushless DC motors give you smooth movement and high control. This helps your robots and medical tools work safely and accurately.

Why is heat management better with brushless DC motors?

Brushless DC motors use efficient designs that move heat out fast. You avoid overheating, so your motor stays safe. This is important when you have little space for cooling.

Why do engineers prefer brushless DC motors for compact projects?

You get high power in a small size.

You save space for other parts.

You spend less time on repairs.

These reasons make brushless DC motors the top choice for compact projects.

See Also

Investing in Mini Brushless Motors For Accurate Performance Needs

Top Battery Operated Electric Motors For Small Devices In 2025

How To Choose The Best Mini DC Motors For Industry Use

Design Tips For Small Vibrating Motors In Tight Spaces

Picking The Ideal Battery Electric Motor Setup For Peak Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry