Comparing Brushed and Brushless 3 Volt Motors

Brushed and brushless 3 Volt Motors are utilized in small devices. Brushed motors feature brushes that facilitate the movement of electric current, while brushless motors employ electronic controllers instead of brushes. Understanding their differences is essential for selecting the appropriate motor. For instance, brushless 3 Volt Motors have a longer lifespan in cordless tools and contribute to energy savings in HVAC systems. These motors play a crucial role in compact devices such as wearables and medical tools. INEED manufactures high-quality 3 Volt Motors for these applications, ensuring optimal performance and durability.

Key Takeaways

Brushed motors are simple and cheap, great for short projects like toys.

Brushless motors work better and last longer, ideal for precise devices like smartwatches.

Pick brushed motors if you want to save money, but use brushless motors for regular use to save energy and repairs.

Knowing how each motor works helps you choose the right one for your needs.

INEED offers many motors for different uses, giving good performance and reliability.

How Brushed 3 Volt Motors Work

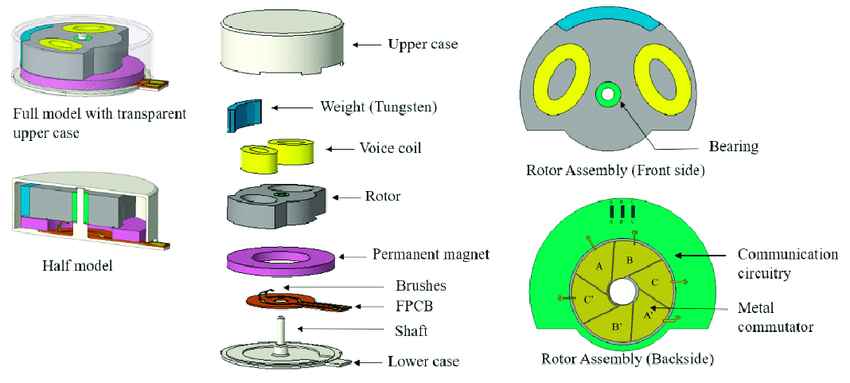

Structure of Brushed Motors

Main parts (like brushes, commutator, rotor, and stator)

Brushed motors have four key parts: brushes, commutator, rotor, and stator. The stator makes a magnetic field. The rotor has windings that work with this field. The commutator links the rotor to the brushes. Brushes send electric current to the motor. These parts work together to make the motor move.

How brushes send current

Brushes are important for sending electric current to the motor. They touch the commutator to let current flow into the rotor windings. This process helps the motor run smoothly and efficiently.

How Brushed Motors Work

How current makes the motor spin

When powered, current flows through brushes and the commutator. It enters the rotor windings inside the stator's magnetic field. This creates electromagnetic force, making the rotor spin. The rotor and stator working together make the motor move.

Why mechanical commutation matters

Mechanical commutation keeps the motor spinning. The commutator changes the current's direction in the rotor windings. This keeps the electromagnetic force steady. It helps the motor turn without stopping.

Features of Brushed 3 Volt Motors

Simple design and easy use

Brushed motors are simple and easy to use. They need little setup, so they’re great for small tasks. Their basic design makes them cheap and easy to fix.

Popular 3-volt motors

Brushed motors work with different voltages. 3-volt motors are common for small devices. Their low voltage is perfect for toys, tools, and gadgets.

How Brushless 3 Volt Motors Work

Structure of Brushless Motors

Main parts (rotor, stator, and electronic controller)

Brushless motors have three main parts: rotor, stator, and controller. The rotor has magnets attached to a shaft or hub. The stator holds windings arranged in three phases. The controller sends current to the windings for smooth operation.

Part | What It Does |

|---|---|

Rotor | Spins with magnets attached to a shaft or hub. |

Stator | Holds windings in a three-phase setup. |

Controller | Sends current to windings using sensor feedback, replacing brushes. |

No brushes or commutator

Brushless motors don’t use brushes or a commutator. This design lowers friction and wear, making them last longer. The rotor’s magnets spin around the fixed stator. The controller replaces the commutator to manage current flow.

How Brushless Motors Work

Role of electronic control

Electronic control is key in brushless motors. The controller sends current to the stator windings based on sensor data. This creates a magnetic field that moves the rotor’s magnets. Without brushes, the motor runs smoothly and reliably.

Magnetic fields create motion

The stator’s magnetic field interacts with the rotor’s magnets to make torque. The controller changes the current to rotate the magnetic field. This makes the rotor spin, giving smooth and efficient movement.

Features of Brushless 3 Volt Motors

High efficiency and accuracy

Brushless motors are very efficient and precise. They work at 85-90% efficiency, better than brushed motors. No brushes mean less energy loss and heat. Devices like power tools last longer with these motors. They also give steady performance at all speeds.

Popular 3-volt motors

Brushless motors work with many voltages, including 3 volts. These motors use little energy but give strong torque. They’re great for small devices like wearables and medical tools. Their long life and low maintenance make them valuable.

Comparing Brushed and Brushless 3 Volt Motors

Performance

Speed and torque differences

Brushed and brushless motors differ in speed and torque. Brushed motors give medium torque, but it drops at high speeds. Brushless motors keep steady torque even at fast speeds. This makes brushless motors better for devices needing constant power, like wearables or medical tools.

Motor Type | Efficiency (%) | Torque Characteristics |

|---|---|---|

Brushed DC motors | Varies | Medium torque, drops with speed |

Brushless DC motors | High | Steady torque at all speeds |

Responsiveness and control

Brushless motors are better at quick responses and control. Their controllers adjust speed precisely, making them reliable for accurate tasks. Brushed motors are simpler but lack this precision. For exact movements, brushless motors are the best choice.

Efficiency

Energy consumption

Energy use is important when picking a motor. Brushless motors work at 85-90% efficiency, while brushed ones are 75-80%. Brushless motors have no brushes, so they lose less energy and save battery life in gadgets like smartwatches or tools.

Motor Type | Efficiency (%) | Additional Notes |

|---|---|---|

Brushed Motors | 75 - 80 | Less efficient due to friction and heat loss. |

Brushless Motors | 85 - 90 | More efficient, saving battery power. |

Heat generation and dissipation

Brushed motors make more heat because of brush friction. This wastes energy and lowers performance over time. Brushless motors, with no friction, handle heat better. They stay cool and work well for long periods.

Durability

Wear and tear on brushes

Brushed motors wear out because of their brushes. Over time, brushes break down and need replacing. This adds maintenance and can stop your device from working.

Longevity of brushless designs

Brushless motors avoid this problem by having no brushes. Their design lasts longer and works more reliably. If you want a motor that needs little care and lasts longer, pick a brushless motor.

Cost

Starting price of brushed vs. brushless motors

When picking between brushed and brushless motors, cost matters. Brushed motors usually cost less at the start. Their simple design and fewer parts make them cheaper. If you have a small budget or need a motor for short use, brushed motors are a good choice.

Brushless motors, however, cost more upfront. They include electronic controllers and advanced parts, raising their price. Even though making brushless motors is simple, the extra electronics add to the cost. This makes them pricier than brushed motors most of the time.

Here’s a quick cost comparison:

Brushed motors are cheaper because they have a basic design.

Brushless motors cost more due to their advanced electronics.

Though brushless motors cost more at first, they save money later. They are efficient and last longer, cutting energy and repair costs. For devices that run a lot or need precision, brushless motors are worth the extra cost.

If your project needs frequent use or high efficiency, pick brushless motors. But for short-term projects or tight budgets, brushed motors are a smart and affordable option.

Applications of Brushed and Brushless 3 Volt Motors

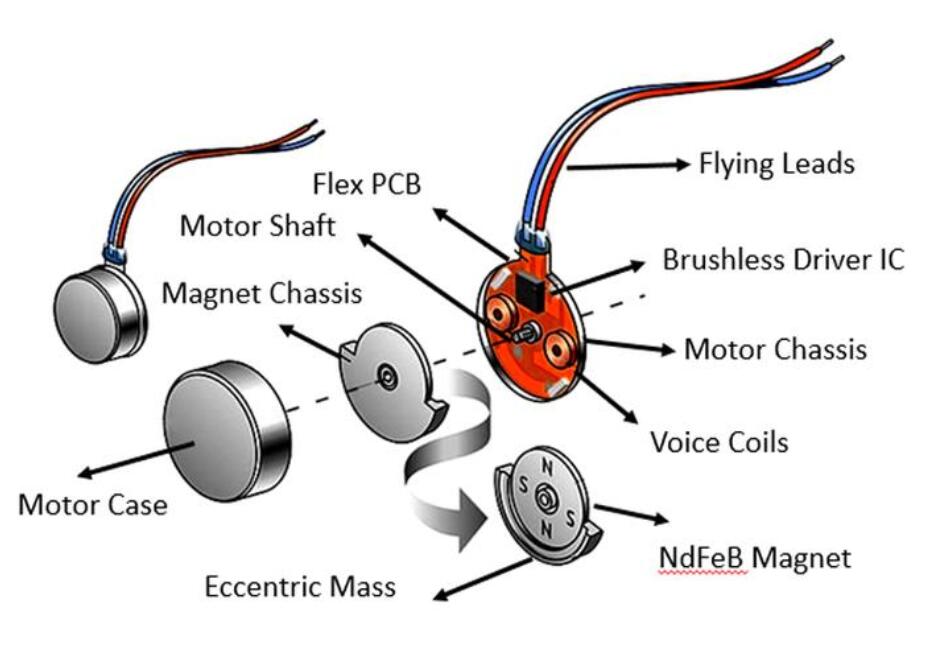

INEED's Coin Vibration Motor and Its Uses

Perfect for wearables, phones, and small gadgets

INEED's coin vibration motor works well in small devices. It is great for wearables, mobile phones, and portable gadgets. These motors give steady vibration feedback in tight spaces. They are tested to last about 72 hours under certain conditions. For example, the motor runs at 3V DC, turning on for one second and off for two seconds. This makes it perfect for devices needing gentle vibration feedback.

Small size and easy to install

The coin vibration motor is small and easy to use. Its size ranges from 7mm to 12mm, fitting into tight spaces. It has a sticky back and wires you can adjust, making setup simple. Whether for a fitness tracker or medical gadget, this motor is a smart and useful choice.

INEED's Coin Brushless BLDC Vibration Motors for Advanced Devices

Great for smartwatches and light gadgets

For light devices like smartwatches, INEED's brushless BLDC motors are ideal. These motors are small but use advanced technology for smooth performance. They have built-in ICs for precise control, making them reliable for important tasks.

Long-lasting and reliable

INEED's brushless motors last longer and work better over time. They don’t have brushes, so there’s less wear and tear. For instance, the 0820 mini motor can run up to 72 hours under specific conditions. This makes it a good choice for devices needing steady performance.

Picking the Right Motor for Your Project

Things to think about (like cost, performance, and lifespan)

When choosing a motor, think about cost, how well it works, and how long it lasts. Brushed motors are cheaper and good for short-term use. Brushless motors cost more but are more efficient and last longer. They’re better for devices used often.

Examples of when to use each motor

For a cheap project like a toy, a brushed motor works well. For a smartwatch or medical gadget, a brushless motor is better. It gives the accuracy and dependability you need. Think about your project’s needs to pick the best motor for it.

Brushed and brushless 3-volt motors are different in many ways. Brushed motors have brushes to move electric current. They are simple and cheap. Brushless motors use controllers instead of brushes. This makes them more efficient and last longer. INEED's Coin Vibration Motor works well in small gadgets. The Coin Brushless BLDC Vibration Motor is great for advanced devices needing precision. SMD Vibration Motors are easy to add to circuit boards. Encapsulated Vibration Motors work well in tough conditions. Pick a motor based on cost, performance, or how long it lasts. Check out INEED's smart motor options for reliable choices.

FAQ

What is the main difference between brushed and brushless motors?

Brushed motors have brushes and a commutator to move current. Brushless motors use an electronic controller instead. Brushless motors last longer and work better. Brushed motors are simpler and cost less.

Why are brushless motors more efficient?

Brushless motors don’t have brushes, so there’s no friction. This saves energy and makes less heat. They work at 85-90% efficiency, which is very high.

Which motor is better for small devices?

Brushless motors are best for small devices needing precision and durability. Brushed motors are good for cheaper or short-term projects. Pick based on your device’s needs.

How long do INEED’s coin vibration motors last?

INEED’s coin vibration motors can last about 72 hours. For example, they run with a 1-second-on and 2-second-off cycle at 3V DC.

Can you customize INEED’s motors for specific applications?

Yes, INEED lets you customize their motors. You can change wire lengths, connectors, and other parts to fit your device.

See Also

Understanding 3V Motors: Key Applications And Selection Criteria

Evaluating Linear Resonant Actuators: Finding The Right Fit

Vibration Motors In Today's Industries: Key Applications Explored

LRA Vibration Motors: Crucial For Advanced Haptic Feedback Solutions

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry