Brush vs Brushless Coin Vibration Motors

The main difference in the Brush vs Brushless debate lies in how the motors operate. Brushless coin vibration motors rely on electronics to function, while brushed motors use physical brushes to generate movement. This distinction significantly impacts motor performance. Brushless motors are more efficient, have a longer lifespan—often running over 10,000 hours—and produce less heat and noise. In contrast, brushed motors require more maintenance and tend to wear out faster due to friction. For those seeking quiet and precise vibration, brushless motors are the preferred choice. However, brushed motors remain a cost-effective option for budget-conscious projects.

Key Takeaways

Brushless motors last longer and are quieter than brushed motors. They use electronics instead of brushes.

Brushed motors cost less at first and react faster. They are good for simple and cheap projects that need quick vibration.

Brushless motors save money over time. They need less care and use less energy. They are best for devices that must work well for many years.

You should pick the right motor for your project. Think about how strong the vibration is, how loud it is, the size, and how long it should last.

Wearables and medical devices work best with brushless motors. These motors are quiet, last a long time, and give better vibration control.

How They Work

Brush Motors

Brush coin vibration motors have a simple design. Inside, there is a flat PCB with a 3-pole commutation circuit. This circuit wraps around a shaft in the center. The rotor has two voice coils and a small weight that is not centered. The weight sits in a flat plastic disc with a bearing. Two brushes under the disc touch the PCB pads. These brushes give power to the voice coils. When the coils get power, they make a magnetic field. This field pushes against a disc magnet attached to the motor’s body. The commutation circuit changes the direction of the magnetic field. This makes the disc spin. Because the weight is off-center, the spinning disc makes the motor shake.

The commutator has six parts linked to the two coils. This setup lets the motor have six different magnet states. It acts like a 6-pole machine. As the disc spins, the resistance through the brushes changes. This change affects how much current the motor uses. The motor needs a certain voltage to start because of the off-center weight. This design helps brush motors react fast and work well for haptic feedback.

Brushless Motors

Brushless coin vibration motors work in another way. They use an off-center spinning mass inside the motor to make vibration. These motors do not have brushes. Instead, they use built-in electronics called IC drivers. The IC driver controls how the motor works. It switches the current with electronics, not brushes. This design cuts down on friction and wear, so the motor lasts longer.

Brushless motors also spin more smoothly and make less noise. The commutation circuit inside keeps the motor running without brushes. This setup makes brushless motors more reliable and good for tough jobs. The table below shows the main differences between Brush and Brushless motors:

Feature/Aspect | Brushless Coin Vibration Motors (BLDC) | Brushed Coin Vibration Motors |

|---|---|---|

Rotor Contact | No brushes; uses IC to detect rotor position | Brushes contact rotor causing friction and wear |

Friction and Wear | Minimal friction, longer lifetime (10x longer MTBF) | Higher friction, shorter lifetime |

Control and Driving | Requires polarity observation; DC voltage only; no PWM driving | Standard DC operation, PWM possible |

Rise/Fall Time | Slower rise/fall times, less suitable for haptic feedback | Faster response, better for haptic feedback |

Reliability and Application | High reliability, suited for medical and high-use applications | Lower reliability, more general use |

Cost | Higher cost due to integrated driver IC | Lower cost |

Tip: Brushless motors are best for projects that need to last long and stay quiet. Brushed motors are better when you need quick action and low price.

Brush vs Brushless: Key Differences

Performance

Performance is a big reason people compare these motors. Brushless motors work better and run more smoothly. They also give more control. These motors can spin very fast, up to 15,000 rpm. They make strong vibrations, often stronger than 1.0G. Brush motors lose some power because of friction from the brushes. This makes them less efficient and louder. Brushless motors react faster, which is good for things like smartwatches. In tests, brushless motors reach top vibration in about 50 milliseconds. Brushed motors can take up to 200 milliseconds. The table below shows how they compare:

Performance Metric | Brushed Coin Vibration Motors | Brushless Coin Vibration Motors |

|---|---|---|

Efficiency | Lower due to brush friction and commutator losses | Higher (85-90%) due to absence of brushes and friction |

Lifetime | Shorter, brushes wear out | Longer, no brushes to wear out |

Noise | Higher noise from brushes and commutator | Less noise due to brushless design |

Rated Speed | Lower and less consistent | Ranges from 9,000 to 15,000 rpm |

Amplitude of Vibration | Moderate, less precise | Higher amplitude (1.0G+ to 1.4G+) |

Control Precision | Limited due to mechanical brushes | High precision via electronic controllers |

Note: Brushless motors are better for devices that need strong, quiet, and exact vibration.

Reliability

Reliability is important when picking a motor. Brushless coin vibration motors last much longer. They do not have brushes that wear out. Data from makers shows brushless motors can work for up to 1,000,000 cycles. Brushed motors may only last about 100,000 cycles. No brushes means fewer things can break. Brushless motors fail less often in real life. This makes them great for things that must work for years, like medical devices. Brushed motors might stop working sooner because their brushes wear down.

Motor Type | Operational Lifespan (cycles) | Test Conditions |

|---|---|---|

Brushless (BLDC) | 1,000,000 | 0.5s on / 0.5s off cycle |

Brush (Double Magnet) | 100,000 | Minimum lifetime stated |

Maintenance

How much care a motor needs can change its cost and ease of use. Brushless coin vibration motors need very little care. They do not have brushes or commutators to replace. Brushed motors need to be checked often. Their brushes must be replaced to keep working well. Users should look at brushed motors every few months. They should clean them and listen for odd sounds. These extra steps take more time and money. Brushless motors help save time and lower the chance of surprise problems.

Brushless motors:

Need almost no care

No brushes to change

Less chance of breaking

Brushed motors:

Need regular checks

Brushes wear out and must be changed

Cleaning and checking alignment is needed

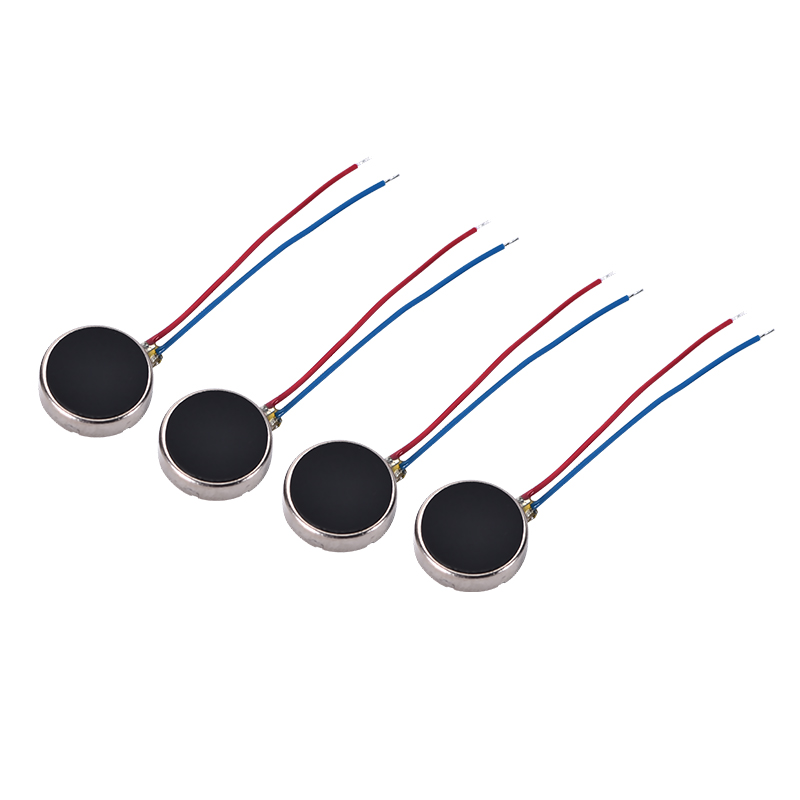

Size and Design

Size and design matter when picking a motor. Both types are small and shaped like coins. They are often less than 12mm wide. This small size helps them fit in thin devices like phones and watches. Brushless motors have built-in drive ICs. This lets them use features like PWM control. Designers can change how strong or fast the vibration is. Brush motors are simple and light. But they cannot handle high heat, so they cannot be used in some ways. Brushless motors come in very small and bigger sizes. They give stronger vibration and more design choices for advanced uses.

Tip: For tiny devices or products that need exact vibration, brushless motors give more choices and work better.

Cost

Cost is a big part of picking a motor. Brushed coin vibration motors cost less at first. This makes them good for cheap or throwaway products. But they do not last as long and need more care. This can make them cost more over time. Brushless motors cost more at first, but they last longer and use less energy. Over time, you save money because you fix them less and pay less for power. For products that need to last and work well, brushless motors can save money in the end.

Feature | Brushless (BLDC) Motor | Brushed (DC) Motor |

|---|---|---|

Initial Cost | Higher upfront cost | Lower upfront cost |

Long-term Cost | Lower due to less maintenance and energy savings | Higher due to maintenance and energy inefficiency |

Picking the right motor depends on if you want to save money now or later and how much you need it to last.

Pros and Cons

When picking between brush and brushless coin vibration motors, people want to know which is better for them. The Brush vs Brushless question is about what each motor is good at and where it is not as good. Knowing the differences helps people pick the right motor for their project.

The table below lists the main good and bad points for each motor type:

Feature/Aspect | Brushed Coin Vibration Motors (ERM) | Brushless Coin Vibration Motors (BLDC) |

|---|---|---|

Price | Low cost, good for budget projects | Higher initial cost |

Installation | Easy to install, compact size with adhesive backing | Small size, fits in compact devices |

Noise | Low noise, but can increase as brushes wear | Very quiet operation |

Technology | Mature and simple technology | Advanced electronics, steady and precise vibrations |

Lifetime | Limited, usually does not reach 1 million cycles | Long lifespan, durable in harsh environments |

Vibration Power | Less powerful than cylindrical motors or LRAs | Adjustable strength, strong and precise vibrations |

Maintenance | Brushes wear out, needs regular checks and cleaning | Almost no maintenance needed |

Customization | Limited options for vibration control | Many options for adjusting vibration strength, speed, and duration |

Application Suitability | Good for simple, low-cost devices where high power is not needed | Ideal for wearables, healthcare, and automotive uses needing reliability |

People pick brushed motors when they want something simple and cheap. These motors are good for projects that do not need to last long or shake very hard. Brushless motors are better for people who need quiet, reliable, and adjustable vibration in small spaces. They last longer and use less energy, so they are better for advanced devices.

The Brush vs Brushless comparison shows why people should think about what their project needs. Brushed motors cost less and are easy to put in, but they do not last as long and are not as strong. Brushless motors cost more at first, but they last longer, are quieter, and give more control. That is why brushless motors are used in wearables and medical tools, while brushed motors are still used in simple, cheap gadgets.

Application Suitability

Wearables

Wearable tech needs motors that are small and strong. Coin vibration motors are good for this because they are flat and easy to stick in place. Their shape lets them fit inside smartwatches and fitness bands. Most wearables use ERM coin vibration motors since they are thin and not expensive. These motors give soft and exact haptic feedback for things like alerts. The closed design keeps out dust and sweat, which is important for things you wear.

Brushless coin vibration motors are now used a lot in wearables. They are quiet and last a long time. They also use less power, so batteries last longer. This is very important for smartwatches and health trackers. Brushless motors do not lose power as they get older. This makes them great for wearables that need steady vibration and to last a long time.

Note: Picking brush or brushless motors for wearables depends on how long the battery should last and how reliable it needs to be.

Consumer Devices

Consumer gadgets use vibration motors to make them better to use. Things like game controllers, barcode scanners, and smart badges use coin vibration motors for haptic feedback. These motors let people feel alerts or actions without needing sound. Both brush and brushless motors are found in these products. Brushless motors are quieter and give more exact feedback. This is important for things like the Muse S headband or WHOOP 4.0 wearable. Brushed motors are still used in cheaper gadgets because they are simple and cost less.

Popular uses include:

Game controllers and joysticks

Smart badges and ID cards

Handheld barcode scanners

Security cameras

Industrial Uses

Factories and tough jobs need motors that can work hard and last. Brushless coin vibration motors are good for things like hobby planes, ground vehicles, and special tools. They do not need much care and last a long time, so machines stop less often. Brushed motors are still used in toys, home gadgets, and car parts. They give good power at low speeds and are cheaper.

Heat and wet air can change how motors work in factories or outside. Motors with covers or special coatings last longer in rough places. Picking the right motor for where it will be used helps it work well and not break early.

Tip: Choosing the right motor for the job and place helps it work better and last longer in factories and other tough spots.

How to Choose

Assessing Needs

To pick the right coin vibration motor, you must know what your project needs. Engineers think about many things before they choose. They look at how strong the vibration should be and how long the device will work. For example, brushless coin vibration motors are great for medical devices. They last over 500,000 cycles and give steady, strong feedback. These motors also use less energy and need almost no care. Devices that run all day, like health trackers, do better with brushless motors.

Size is important, too. Some projects need a tiny motor to fit in small spaces. Brush coin motors are small and fit well in little gadgets. But they wear out faster and need more fixing. Engineers also check how loud the motor is and if it gets hot. Brushless motors are quieter and stay cooler, which is good for sensitive places.

The table below shows which features match each motor type:

Motor Type | Key Features | Applications and Suitability |

|---|---|---|

Brush Coin Motors | Use brushes, lower durability, need maintenance, compact | Good for small devices, not ideal for long-term or harsh use |

Brushless Coin Motors | No brushes, longer lifespan, higher efficiency, reliable performance | Best for long-lasting, strong vibration needs in medical, automotive, and high-end wearables |

Making the Decision

After looking at what is needed, engineers compare the good and bad points. Brush coin motors cost less at first, so they help with cheap projects. But they need more care and do not last as long. Brushless motors cost more, but they last longer and need less fixing. They also work better in devices that need top performance.

A cost-benefit table helps show why the choice is important:

Feature | Brush (PMDC) Motor | Brushless (BLDC) Motor |

|---|---|---|

Initial Cost | Lower, good for simple uses | Higher, complex design |

Maintenance | Needs brush replacement | Almost no maintenance |

Operational Cost | Moderate, due to upkeep and shorter life | Lower, thanks to efficiency and long life |

Performance | Good for basic needs | Best for precision and quiet operation |

Lifespan | Shorter | Longer |

Best Use | Budget, simple devices | High-performance, critical devices |

Tip: When picking between Brush and Brushless, engineers should ask: Does the device need to last a long time? Is strong, quiet vibration needed? If yes, brushless motors are better. For simple, cheap gadgets, brush motors might be enough.

Picking the right coin vibration motor depends on what your project needs. The choice between Brush and Brushless changes how well the motor works, how long it lasts, and how much it costs. You should think about things like steady voltage, keeping cool, and saving energy. You can also change things like how strong the vibration is or how long the wires are. This helps the motor fit the device better. Brushless motors are best for wearables and medical tools that must last a long time and stay quiet. Brushed motors are good for simple and cheap gadgets. To get the best results, engineers should check how much power is needed, how much space there is, and how often the device can be fixed.

FAQ

Why do brushless coin vibration motors last longer than brushed ones?

Brushless motors do not have brushes that rub against parts. This design reduces friction and wear. The motor runs cooler and does not need brush replacements. As a result, brushless motors work for many more hours.

Tip: Longer life means fewer repairs and less downtime.

Why do engineers choose brushed motors for low-cost devices?

Brushed motors cost less to make and buy. They have a simple design and work well for basic tasks. Engineers pick them when they want to save money and do not need long-lasting performance.

Why does noise differ between brush and brushless motors?

Brushed motors create noise because the brushes touch moving parts. This contact causes sound and vibration. Brushless motors use electronics instead, so they run much quieter.

Why do wearables often use brushless coin vibration motors?

Wearables need motors that last a long time and use little power. Brushless motors fit these needs. They also stay quiet and give steady vibration, which improves the user experience.

Why is maintenance lower for brushless motors?

Brushless motors do not have brushes that wear out. The electronic parts inside need little care. This design means users spend less time fixing or checking the motor.

See Also

Differences Between Brushed And Brushless 3V Motors Explained

Why Mini Brushless Motors Are Ideal For Precision Use

Top Ten Vibration Motors To Enhance Your Arduino Builds

Engineering Basics Of Frequency For Coin Vibration Motor Design

Five Essential Specs Every Coin Vibration Motor Needs To Meet

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry