Battery Powered Electric Motors: Choosing the Right Configuration for Optimal Performance

Choosing the right motor setup affects how well your system works. It changes energy use and performance. For example:

Motor type 1 uses the least energy, but motor type 2 uses 6.5% more energy.

Using setups like gearboxes or multi-mode systems can save up to 18.86% on energy.

Battery powered electric motors work best when chosen for specific tasks. This helps them last longer and lowers costs over time.

Key Takeaways

Pick the right motor for your needs. Brushed motors are cheaper but less powerful. Brushless motors last longer and work better for tough jobs.

Learn about duty cycles to use motors well. Continuous duty is good for steady work. Intermittent duty saves power for short tasks.

Keep motors at a safe temperature of 15–20 °C. This keeps them working well and helps them last longer.

Match power needs with battery life. Use layered battery systems to charge faster and keep batteries healthy.

Test motors before deciding. Check how they work and if they are safe for your project.

Types of Battery Powered Electric Motors

Brushed DC Motors

Brushed DC motors are simple and affordable. They use brushes to send electricity to the rotor, making it spin. Their basic design keeps costs low and makes them easy to use. If you're on a budget, these motors are a good choice.

But, the brushes wear out over time. You’ll need to replace them regularly. This adds to long-term costs, especially if the motor runs all the time. If your system has planned maintenance, replacing brushes might not be a big problem.

These motors are less efficient than brushless ones. The brushes cause friction, which wastes energy and creates heat. Still, brushed motors are dependable for jobs where saving money matters more than efficiency.

Brushless DC Motors

Brushless DC motors are newer and don’t use brushes. Instead, they use electronic controllers to move electricity. This makes them much more efficient, with over 90% efficiency compared to about 60% for brushed motors.

They also last longer. Brushless motors can run for over 10,000 hours, while brushed motors usually last 3,000–5,000 hours. They are quieter, smaller, and lighter, which is great for tight spaces or quiet environments.

The downside is their higher price. Brushless motors need advanced electronics, which makes them cost more. But their low upkeep and better performance often make them worth the extra money.

Comparing Pros and Cons

Here’s a simple comparison to help you choose:

Property | Brushed Motor | Brushless Motor |

|---|---|---|

High | Low | |

Lifespan | Short (brushes wear out) | Long (no brushes) |

Efficiency | Medium | High |

Noise Levels | Loud | Quiet |

Cost | Cheapest | Higher |

Think about what matters most for your project. If saving money is key, brushed motors are a smart pick. If you need efficiency and durability, brushless motors are the best choice.

Duty Cycles and Their Importance

What Are Duty Cycles?

A duty cycle shows how long a motor runs versus rests. It is written as a percentage. For example, if a motor works for 30 seconds and rests for 30 seconds, its duty cycle is 50%. This helps us use motors wisely.

The IEC (International Electrotechnical Commission) made the IEC 60034-1 standard. It explains 10 duty types, named S1 to S10. These types show how motor use affects its performance, efficiency, and life.

Duty Type | Description |

|---|---|

Continuous Duty | Runs non-stop under normal conditions for steady work. |

Short-Time Duty | Works briefly, then cools down to avoid overheating. |

Intermittent Duty | Switches between running and resting to save energy and last longer. |

Continuous vs. Intermittent Use

Continuous use means the motor runs without stopping. It stays cool and works steadily. This is great for things like fans or conveyor belts.

Intermittent use means the motor works, then rests. It can handle heavy loads for short times without overheating. This is good for lifting or tools that don’t run all the time.

Aspect | Continuous Use | Intermittent Use |

|---|---|---|

Current Ratings | Stays within normal limits | Can go above normal briefly |

Thermal Limits | Keeps cool during use | May get hotter during short bursts |

Load Holding | Not made for holding loads | Made to hold loads for short times |

Control Type | Often uses simple control | Uses advanced control systems |

Picking the Right Duty Cycle

Choosing the right duty cycle helps motors work better and last longer. For constant use, pick a motor made for continuous duty. For short tasks, choose an intermittent duty motor to save energy and reduce wear.

Battery-powered motors depend a lot on duty cycles. A motor’s power comes from speed, torque, and duty cycle. Matching the duty cycle to the job improves battery life and efficiency.

Power and Torque Basics

Figuring Out Power Needs

Knowing how much power your motor needs is important. Power comes from speed and torque. It is measured in kilowatts or horsepower. You can find mechanical power using this formula:

Power (kW) = Torque (Nm) × Speed (RPM) ÷ 9.5488

This formula shows how much power your motor needs for a job. For AC systems, use this formula instead:

Power (W) = Voltage (V) × Current (A) × Power Factor (PF)

Temperature affects how well motors work. Motors work best between 15–20 °C. Efficiency is highest at 16 kWh/100 km. If it’s hotter than 30 °C or colder than 7 °C, efficiency drops by 12.5%. Keep motors in the right temperature range to save energy and make them last longer.

Learning About Torque-Speed Curves

Torque-speed curves show how motors act with different loads. When torque goes up, speed goes down. This helps you pick the right motor for your needs.

Parameter | What It Means |

|---|---|

Speed (N) | Speed slows as torque increases. |

Efficiency (η) | Best at low torque, showing where the motor works best. |

Torque (T) | The load the motor can handle, shown on the X-axis. |

Current (I) | Grows with torque, showing how much energy the motor uses. |

Output Power (P) | The motor's power output, measured in Watts. |

Looking at these curves helps you find the best working range. This keeps the motor running well without overloading it.

Balancing Power and Battery Use

It’s important to balance power and battery life. A multi-level battery system can help. This setup uses batteries of different sizes and charge rates. It makes charging faster and keeps batteries healthy.

For example, tests show this system charges quickly without hurting the battery. Managing power well can make batteries last longer and lower costs. Always match your motor’s power needs to your battery’s size for the best results.

Efficiency and Performance Trade-Offs

Key Factors Affecting Efficiency

How well battery-powered motors work depends on many things. These include the materials used, how the motor is built, and how it is used. Good materials lower energy loss by reducing resistance. A well-designed motor moves energy smoothly, cutting down friction and heat. Conditions like temperature and workload also affect efficiency.

A study shows that 91% of companies care about energy efficiency when picking motors. Also, 94% focus on being eco-friendly, and 99% check long-term savings from efficient systems. These numbers prove how important efficiency is for saving money and improving performance.

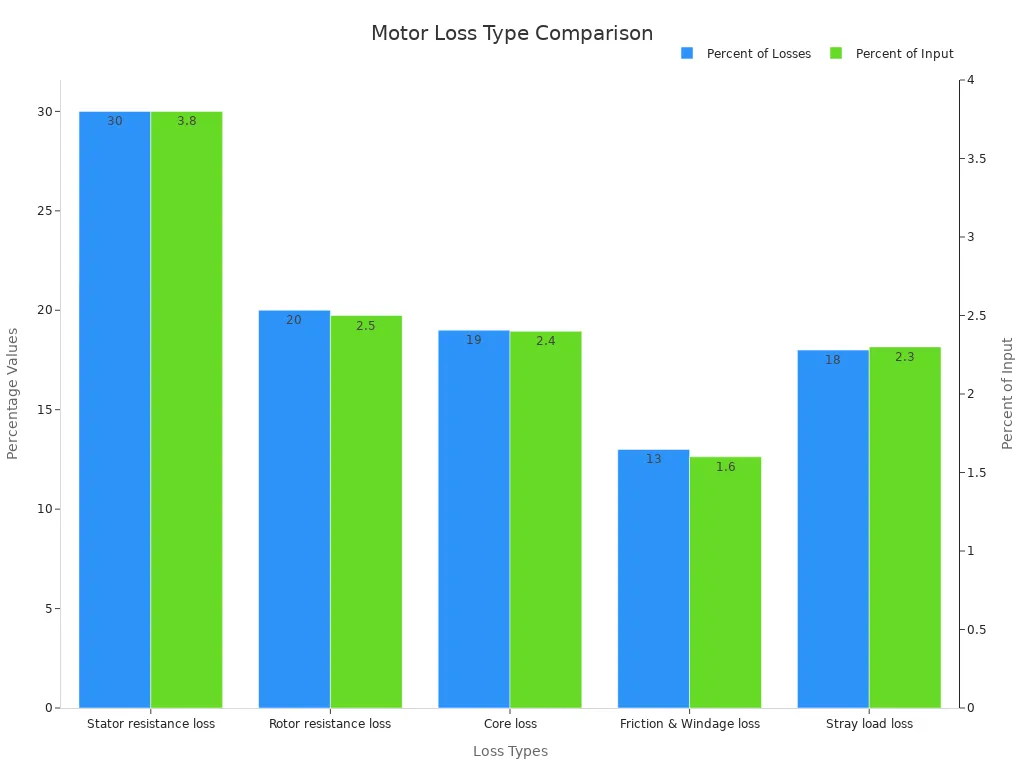

Motor losses show where energy is wasted. The table below explains the types of losses:

Loss Type | Percent of Losses | Percent of Input |

|---|---|---|

Stator resistance loss | 30 | 3.8 |

Rotor resistance loss | 20 | 2.5 |

Core loss | 19 | 2.4 |

Friction & Windage loss | 13 | 1.6 |

Stray load loss | 18 | 2.3 |

Total losses | 100 | 12.6 |

These losses show where motors can improve. For example, lowering friction and windage loss can boost how well a motor works.

Balancing Efficiency with Performance

Finding the right balance between efficiency and performance is important. A motor made for efficiency might lose speed or power. For example, studies show changing how fast electric cars speed up saves energy but wears out batteries faster. This trade-off needs careful thought.

Think about what your project needs. If you need strong power, focus on performance. If your motor will run for long hours, aim for efficiency. Balancing these factors helps get the best results without harming the battery.

Optimizing Efficiency for Applications

To make motors more efficient, match them to the job. First, check the workload and duty cycle. Pick a motor built for those tasks. For example, motors for short tasks save energy, while motors for steady work are better for long use.

Keeping motors at the right temperature also helps. Motors work best between 15–20 °C. If it’s too hot or cold, efficiency can drop by 12.5%. Keep motors in their ideal range for better performance.

Lastly, use advanced tools like multi-level battery systems. These systems charge faster and make batteries last longer. By choosing the right motor and tools, you can save energy and still get great performance.

Environmental and Operational Factors

How Temperature and Humidity Affect Motors

Temperature and humidity can change how well motors work. Motors perform best in mild conditions, between 15–20 °C. If it gets hotter than 30 °C or colder than 7 °C, efficiency can drop by 12.5%. High humidity can cause water to form inside the motor. This might lead to short circuits or rust on parts.

Engineers use formulas to study these effects. For example:

Aspect | What It Explains |

|---|---|

Functional Unit | Impact per kilometer traveled |

Power Loss Formula | $EL_{be} = D_{v} \times CEL_{drm} \times (1 - \eta_c)$ |

Extra Power Formula | $EL_{ex} = \frac{W_{b}}{W_{v}} \times CEL_{w} \times \frac{CEL_{drm}}{\eta_c} \times D_{v}$ |

Energy Used Formula | $EL_{u} = CA_{b} \times INT(\frac{D_{v}}{D_{r}})$ |

Regional Study | Looks at five areas: Global, China, Japan, Europe, US |

Environmental Impact | Changes in resource use, pollution, and ecosystem damage |

These tools help predict how weather affects motor efficiency and energy use.

Handling Vibrations and Shocks

Motors often deal with vibrations and shocks, especially in factories or vehicles. These forces can break parts, lower reliability, and shorten motor life.

Important factors to check for vibration and shock resistance are:

Speed: Measures how fast the motor moves during operation.

Acceleration: Tracks how quickly the motor’s movement increases.

Distance: Shows how far the motor moves from its position.

Strength: Measures how much force the motor can handle.

Repetition: Checks how often vibrations happen in a set time.

Resonance: Happens when outside forces match the motor’s natural frequency.

Knowing these factors helps you pick motors that can handle tough conditions. This improves reliability and makes them last longer.

Following Environmental Rules

Environmental rules make sure motors are safe and eco-friendly. These rules differ by region but focus on saving energy, cutting pollution, and working safely in various settings.

For example, standards like ISO 14001 or RoHS show that a motor is better for the environment. Motors meeting these rules use fewer resources and create less pollution.

When buying a motor, check if it follows these rules. This ensures good performance and avoids legal or safety problems.

Steps to Select the Right Motor

Understanding What Your Application Needs

To pick the right motor, know what your project needs. Start by figuring out the motor’s tasks. Will it run all the time or take breaks? Does it need to lift heavy things or work in tough conditions? These questions help you decide the motor’s duty cycle, power, and torque needs.

Think about the environment too. If the motor will face high heat or wet air, choose one built for those conditions. Matching the motor to the job makes it work better and last longer.

Comparing Motor Features

After knowing your needs, compare motor features to find the best one. Focus on important details like:

Power Requirements: Make sure the motor gives enough power for the job.

Torque: Check if the motor can handle the needed force.

Duty Cycles: Match the motor’s running time to your project’s needs.

Thermal Limits: Ensure the motor works in your environment’s temperature range.

Efficiency: Pick motors that save energy and lower costs.

Environmental Factors: Think about how heat, humidity, or other conditions affect the motor.

Comparing these features helps you choose wisely. For better results, use tools like the JAYA algorithm, which balances performance and design needs. The table below shows ways to improve motor choices:

Evidence Type | What It Explains |

|---|---|

Optimization Design | Study parts like stator size and magnetic strength. |

Algorithm Application | Use the JAYA algorithm to make smarter motor choices. |

Parameter Selection | Pick the right settings to get better results. |

Testing Before You Decide

Before choosing a motor, test it to see if it works well. Functional tests check basic things like starting, stopping, and speed control. Performance tests measure how efficient it is and how much power and torque it gives. Standards like IEC 60034 and IEEE 112 guide these tests.

Important testing steps include:

Checking if the motor handles changes in load.

Measuring efficiency and power during real-world use.

Watching temperature to keep it safe.

Testing makes sure the motor works as expected and meets safety rules. This step helps avoid mistakes and ensures the motor lasts a long time.

Picking the right motor setup helps your system work well. Matching the motor type, duty cycle, power, and environment to your needs boosts performance and helps the planet. For example:

Research on electric race cars shows that using the right parts improves efficiency and lowers harm to the environment.

Better motor designs use fewer rare materials like aluminum and lithium, making them more eco-friendly.

Start by knowing exactly what your project needs. For tricky tasks, ask experts for advice to get the best outcome. This way, you can make the most of battery-powered motors and achieve lasting success.

FAQ

What matters most when picking a battery-powered motor?

Think about what your project needs. Check the motor’s power, torque, duty cycle, and environment. Choosing the right match improves how well it works.

How can I figure out the power my motor needs?

Use this formula:

Power (kW) = Torque (Nm) × Speed (RPM) ÷ 9.5488

This shows how much power the motor needs based on torque and speed.

Can a brushed motor run all the time?

Brushed motors can run non-stop, but their brushes wear out quickly. Brushless motors are better for long use. They last longer and need less fixing.

How does heat or cold affect motor efficiency?

Motors work best between 15–20 °C. If it’s hotter than 30 °C or colder than 7 °C, efficiency drops by 12.5%. Keep motors in this range for better results.

What’s the difference between continuous and intermittent duty cycles?

Continuous duty means the motor runs without stopping. Intermittent duty means it runs, then rests. Pick the right one to save energy and avoid overheating.

See Also

Choosing Electric Motor Batteries: Performance, Uses, and Selection

Types of Small Battery Motors: Applications and Power Efficiency

Investing in Mini Brushless Motors for Precision Applications

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry