Small Battery Operated Motors: Types, Applications, and Power Optimization for ERM Vibration Systems

Battery Operated Motors are widely utilized in numerous small gadgets, including smartphones and wearable devices. These motors play a crucial role in keeping devices compact while ensuring optimal performance. In gadgets that feature touch feedback, ERM vibration systems are essential as they generate vibrations that enhance user experience and interaction. Optimizing power usage in these systems not only improves their functionality but also conserves battery life. For example, studies indicate a 24% improvement in performance when resistance is adjusted. Additionally, tests reveal a 19% boost in efficiency. These advancements enable devices to operate effectively without unnecessary energy consumption.

Key Takeaways

Learn about three small battery-powered motor types: brushed, brushless, and coreless. Each has special features and works best for certain uses.

Save power by picking the right motor for your device. This helps it work better and makes the battery last longer.

Add vibrations to gadgets for a better user experience. Small motors make devices more fun and easier to use.

Use good batteries like lithium-ion or nickel-metal hydride. These batteries last longer and charge faster for small gadgets.

Try advanced control methods like PWM to improve motor use. These techniques save energy and make devices work better.

Types of Small Battery Operated Motors for ERM Systems

Brushed DC Motors

Brushed DC motors are very common in ERM systems. These motors use brushes and a commutator to move electricity. This electricity makes the motor spin. Their simple design keeps them cheap and easy to fix. These motors work well when cost and simplicity are important.

Brushless DC Motors

Brushless DC motors (BLDC) are newer than brushed motors. They don’t use brushes. Instead, they use electronics to control movement. This makes them last longer and need less fixing. These motors save energy and fit well in small devices.

They use less energy, so they can be smaller and cheaper.

Built-in controls make switching from brushed motors easier.

BLDC motors act like brushed motors, so upgrades are simple.

These features make brushless motors popular for advanced ERM systems in gadgets like wearables.

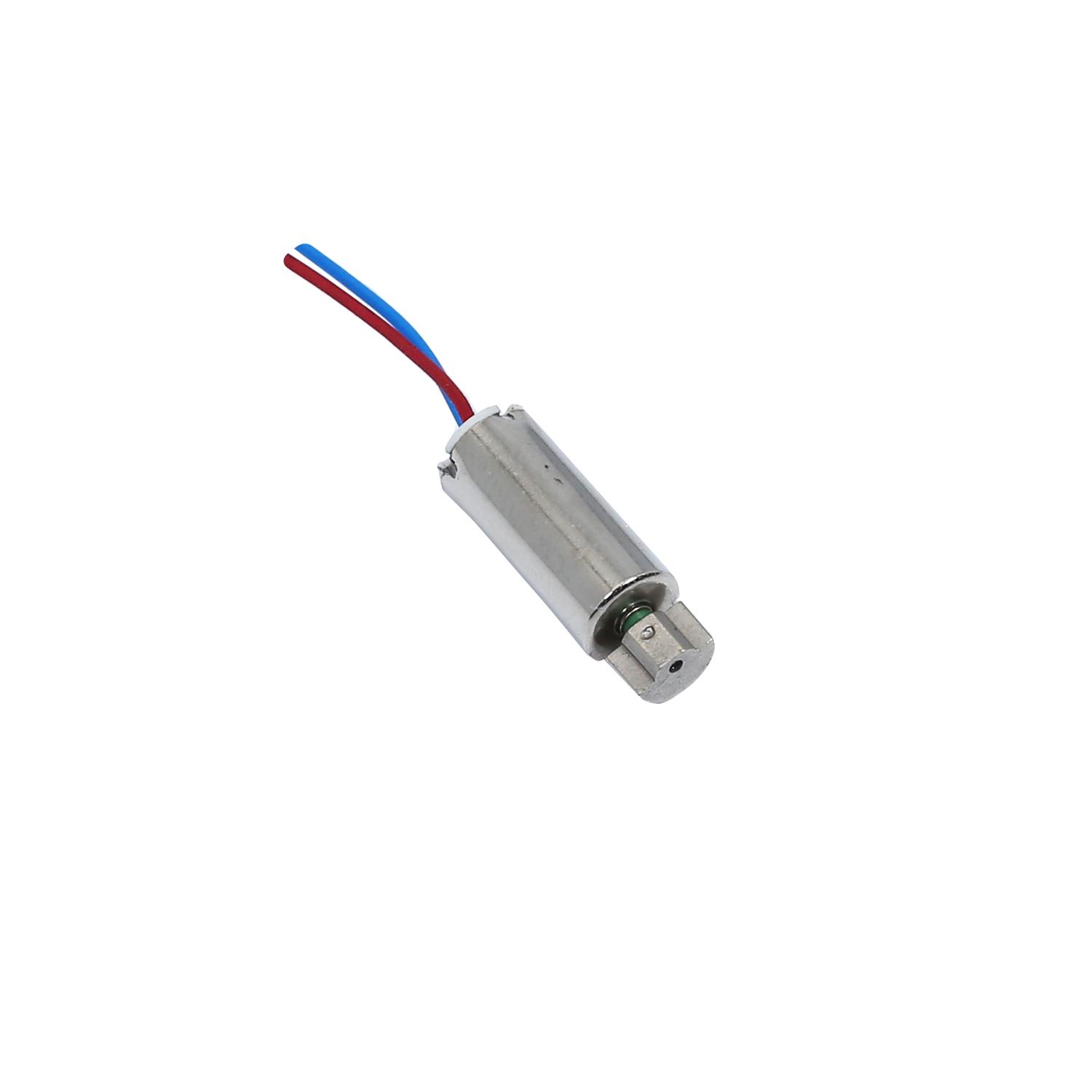

Coreless Motors

Coreless motors are another good choice for ERM systems. They don’t have an iron core in the rotor. This makes them spin faster and use less energy. These motors are great for devices needing quick movement and lightweight parts.

Coreless motors work well in portable gadgets like fitness trackers. Their small size and low energy use are perfect for tight spaces. They also help batteries last longer, improving device performance.

Comparing Motor Types for ERM Systems

Choosing a motor for ERM systems needs careful thought. Each motor type—brushed, brushless, and coreless—has pros and cons. Knowing these differences helps you pick the best one.

Brushed DC Motors

Brushed DC motors are simple and cheap. They use brushes to move electricity, making repairs easy. These motors give strong power, great for high-energy tasks. But, brushes wear out, so they don’t last as long. If you want low cost and easy use, this motor is a good choice.

Brushless DC Motors

Brushless DC motors are more advanced. They don’t have brushes, so they last longer. Fewer parts mean less fixing is needed. These motors are quiet and save energy, perfect for modern gadgets like smartwatches. They cost more at first but are worth it for long-term use in high-tech systems.

Coreless Motors

Coreless motors are small and light. They spin quickly and use less power. This makes them great for small devices where space and battery life matter. They respond fast, improving how gadgets like fitness trackers work. If you need a motor for tiny, energy-saving devices, coreless motors are a smart pick.

Motor Type | Main Benefits | Downsides | Best Uses |

|---|---|---|---|

Brushed DC | Cheap, easy to fix | Wears out faster | Simple ERM systems |

Brushless DC | Long-lasting, quiet, efficient | Costs more | Wearables, advanced systems |

Coreless | Light, fast, energy-efficient | More expensive than brushed | Small, portable devices |

Each motor type fits different needs. Match the motor to your device for better performance and energy use.

Applications of Small Battery Operated Motors in ERM Vibration Systems

Haptic Feedback in Consumer Electronics

You feel haptic feedback daily in gadgets like phones and smartwatches. Small motors create vibrations for alerts and better interactions. These vibrations mimic touch, connecting digital actions to real sensations. For example, a text message vibration lets you know silently, making it more convenient.

In gaming, vibration motors make games feel more real. They give feedback during play, making virtual worlds more exciting. By adding these motors, devices become easier and more fun to use.

Key Benefits of Haptic Feedback in Consumer Electronics:

Makes devices more engaging with touch-like sensations.

Alerts are clear without needing sound.

Adds realism to games with accurate vibrations.

Wearable Devices and Medical Equipment

Wearables use small motors for precise vibrations in alerts. Fitness trackers buzz when you hit goals, like steps. Smartwatches vibrate for alarms, waking you up quietly. These motors are tiny and save energy, perfect for battery-powered wearables.

Medical devices also depend on vibration motors. Insulin pumps and health monitors use them for important alerts. Their dependability helps these devices work well, improving patient safety.

Why Small Motors Are Essential in Wearables and Medical Equipment:

Small size fits tight spaces in devices.

Energy-saving design helps batteries last longer.

Reliable vibrations ensure important alerts are noticed.

Industrial and Automotive Applications

In factories, vibration motors check machine health. They spot unusual vibrations, warning about possible problems early. This helps avoid costly repairs and downtime.

Cars also use these motors for safety. They give feedback through steering wheels or seats. For example, a vibrating wheel warns if you drift from your lane. This helps drivers react faster and stay safe.

Segment | Market Share | Importance in Industry |

|---|---|---|

Vibration Sensors | > 45% | Helps find motor issues early by tracking vibrations. |

Micro Motors | N/A | Powers small gadgets with precise motion and energy-saving features. |

Small motors improve safety, efficiency, and user experience in many industries.

Emerging Use Cases in IoT and Robotics

Small motors are changing IoT and robotics. They are compact, efficient, and reliable. These motors help improve automation, connectivity, and precision.

Application Area | Description |

|---|---|

Robotics | Small motors are cleaner and safer than fluid-powered systems. |

Automation | IoT lets you monitor and control systems remotely. |

Medical Devices | FDA rules push for smarter motors with cloud features. |

Robots use these motors instead of fluid systems. This makes them cleaner and safer. You can find them in robotic arms, drones, and self-driving cars. In factories, IoT motors allow remote control, making work faster and easier. For medical tools, FDA rules require connected motors. These motors help track devices and improve patient care.

These motors are versatile and useful. They save energy, improve precision, and connect to real-time data. As technology grows, they will be used in even more ways.

INEED Solutions for Wearable Smart Devices and Barcode Scanners

INEED creates special motors for wearables and barcode scanners. Their motors solve problems like power use and durability. For wearables, INEED’s LRA motors give accurate vibrations. This improves how users feel the device. Flexible circuit boards make assembly faster and more reliable. These motors work well in smartwatches and pass tough tests.

For barcode scanners, INEED’s 4mm motor gives strong feedback. It fits into designs without big changes. Its coils are stronger, so it lasts longer. The motor meets strict rules for vibration and power, perfect for busy stores.

Choosing INEED means better motors for modern devices. Their designs boost performance and make users happy.

Power Optimization Strategies for Small Battery Operated Motors

Voltage Regulation and Power Management

Keeping voltage steady helps batteries last longer. Stable voltage stops energy waste and keeps motors working well. Power systems, like energy-sharing tools, spread power smartly across devices. This cuts down on wasted energy, which is vital for portable gadgets.

Studies show ways to save energy:

Making motors more efficient lowers energy use in electric cars. These ideas can work for small motors too.

Smart energy tools, like fuzzy logic and planning, save power and extend battery life.

Using these methods makes motors work better and saves energy.

Efficient Motor Design and Material Selection

A motor’s design and materials affect how well it works. Light materials, like aluminum, make motors weigh less. Lighter motors need less energy to run. Strong magnets and good copper wires help motors work better by moving energy efficiently.

Coreless motors are a great example of smart design. They don’t have an iron core, so they spin faster and use less energy. Picking strong and conductive materials makes motors last longer and work better. A well-made motor saves energy and stays reliable.

Advanced Control Techniques (e.g., PWM, Feedback Systems)

Special control methods, like PWM and feedback systems, improve motor performance. PWM changes power by turning it on and off quickly. This gives better control and saves energy. Feedback systems check motor performance and adjust it to stay efficient.

Tests show these methods work well:

Test Type | Improvement Seen |

|---|---|

Constant speed with closed-loop control | 39% better performance |

Frequency response tests | Faster and smoother results |

Also:

Better current control tools help motors handle power changes.

Observers track changes and improve motor response under heavy loads.

These techniques make motors run smoother and help batteries last longer.

Battery Selection and Energy Storage Solutions

Picking the right battery helps small motors work better. Batteries should give steady power and stay small in size. Lithium-ion batteries are a top choice for devices with small motors. They last long, charge fast, and store lots of energy. These features make them great for wearables and medical gadgets.

Nickel-metal hydride (NiMH) batteries are another good option. They are safer and greener than older nickel-cadmium batteries. NiMH batteries are good for devices needing medium power and frequent charging. Alkaline batteries are cheaper and work well for low-power devices, though they are less common in advanced gadgets.

Energy storage is also important. Supercapacitors store energy quickly and release it in short bursts. This makes them useful for motors needing quick power boosts. Using both batteries and supercapacitors together can save energy and make devices last longer. Solar panels and other energy-harvesting tools can also recharge batteries as you use them.

INEED's Coreless Vibration Motor and LRA Electrical Motor LRA2024A-1088F

INEED makes smart motors for vibration systems. Their coreless vibration motor is light and reacts fast. Its design reduces energy waste, making it perfect for small gadgets like fitness trackers. This motor works well and saves battery life.

The LRA Electrical Motor LRA2024A-1088F is another great choice. It gives accurate vibrations and works across many frequencies. It uses little power but creates strong vibrations, ideal for VR systems and gaming controllers. This motor is tough and lasts through one million uses, making it a smart, long-term option.

Both motors show INEED’s focus on quality and new ideas. They work for many devices, improving performance and user experience.

Picking the right motor for ERM systems is important. It helps your device work well and satisfy users. Different motors have unique advantages, so choose one that fits your needs. Saving power is key to better performance and longer battery life. Devices with small motors benefit from using energy wisely. This improves how they work and last. Check out INEED's vibration motors for options that match your device. They offer solutions to boost performance and meet your goals.

FAQ

What is an ERM vibration motor, and how does it work?

An ERM motor makes vibrations by spinning a weight that’s off-balance. This spinning creates the shaking you feel as feedback. These small motors are common in gadgets like phones and smartwatches.

How do I choose the right motor for my device?

Think about your device's size, power, and purpose. For small gadgets, coreless or brushless motors are great. If you need strong and lasting motors, pick brushless ones. Choose a motor that fits your device for the best results.

Why is power optimization important for small motors?

Saving power helps batteries last longer and motors work better. It keeps your device running without needing to charge often. Using steady voltage, good materials, and smart controls saves energy and boosts performance.

Can vibration motors be customized for specific applications?

Yes, vibration motors can be made to match your needs. You can adjust their strength, speed, and size. INEED offers custom motors to fit your device perfectly. Custom motors improve how devices work and feel.

What industries benefit most from vibration motors?

Vibration motors are used in electronics, wearables, medical tools, and cars. They give feedback, alerts, and safety features. Motors are also helpful in IoT and robots for better control and accuracy.

💡 Tip: Check out INEED’s custom motors for solutions made for your industry.

See Also

Understanding 3V Motors: Uses, Features, And Choosing Guide

A Comprehensive Overview Of Vibration Motors: Varieties And Selection

Investigating Vibration Motor Uses Across Contemporary Industries

Choosing Electric Motor Batteries: Efficiency, Use Cases, And Performance

LRA Vibration Motors: Key Elements Driving Today's Haptic Feedback Technology

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry