Understanding Back EMF in ERM Vibration Motors: How It Enhances Performance

Back EMF means the voltage a motor makes while running. This voltage moves opposite to the voltage powering the motor. In ERM vibration motors, back EMF is very important for better performance. It controls speed, keeps the motor steady, and saves energy. Knowing how back EMF works helps make motors run smoother and use less power. This is useful for improving motor performance in many different uses.

Key Takeaways

Back EMF is important for how motors work. It controls speed, keeps motors steady, and saves power.

Knowing about back EMF helps motors run smoothly. It stops quick speed changes and lowers vibrations, making them better to use.

Back EMF makes motors use less energy. It slows down electric flow, stops overheating, and helps motors last longer.

In gadgets like smartwatches and vibration systems, back EMF keeps vibrations steady. This improves how they work and saves battery life.

Improving back EMF makes motors more reliable. It keeps them stable and efficient, so they work well in many devices.

What Is Back EMF?

Definition and Basic Principles

Back EMF is the voltage a motor creates while running. It pushes against the voltage you give to the motor. This happens because of electromagnetism rules. Faraday’s Law says changing magnetic fields make voltage. Back EMF resists the current flowing in the motor. Lenz’s Law explains that this current fights the magnetic change that made it. These laws help back EMF stop the motor from using too much power.

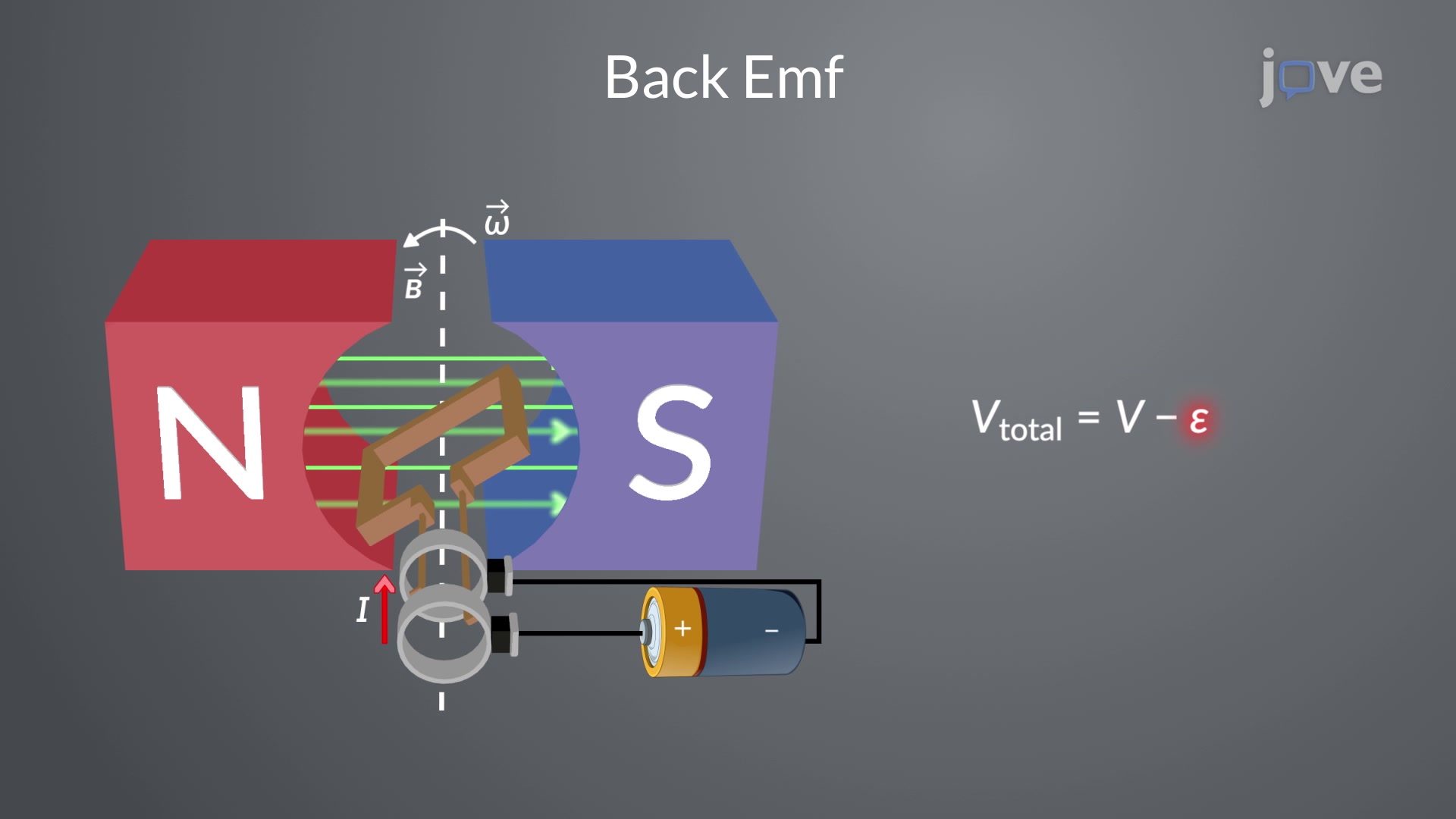

The formula for back EMF is:

[ \epsilon_i = \epsilon_S - I(R_f + RE_a) ]

This shows how back EMF comes from the voltage you supply and resistance losses. Another formula, (V = L * (dI/dt)), shows back EMF depends on how fast current changes. These ideas make back EMF very important for motors.

How Back EMF Is Generated in ERM Vibration Motors

In ERM motors, back EMF happens when the armature spins. The armature moves inside the magnetic field made by the coils. This movement changes the magnetic field, creating voltage opposite to the applied voltage.

Think of back EMF as the motor’s way to stay balanced. When the armature spins faster, the magnetic field changes quicker, making more back EMF. This helps the motor use less power and work steadily. Without back EMF, the motor would waste energy and overheat.

Relationship Between Back EMF and Motor Speed

Back EMF and motor speed are connected. When the motor spins faster, the magnetic field changes faster. This makes more back EMF.

This connection helps control how the motor works. If you give the motor more voltage, it spins faster and makes more back EMF. The back EMF then limits the current, stopping the motor from overloading. This keeps the motor safe and efficient, even at high speeds.

By knowing this, you can make ERM motors work better. Whether for wearables or haptic systems, understanding back EMF helps motors run smoother and save energy.

How Back EMF Works in ERM Vibration Motors

Interaction Between Back EMF and Applied Voltage

When voltage powers an ERM motor, the armature starts spinning. As it spins, it creates Back EMF, which pushes against the voltage. This balance helps the motor work smoothly. Faster spinning makes stronger Back EMF. This reduces the current the motor uses, saving energy.

Think of Back EMF as the motor's way to protect itself. It stops the motor from using too much power, even with higher voltage. This keeps the motor safe and helps it last longer. Without Back EMF, the motor could overheat and get damaged.

Role in Speed Regulation and Torque Control

Back EMF helps control how fast the motor spins. When speed increases, Back EMF also increases. This limits the current, keeping the speed steady. This self-control makes the motor work well, even with changing loads.

Torque, or the force that makes things spin, is also affected by Back EMF. If the motor faces a heavier load, it slows down a bit. This lowers Back EMF, letting more current flow. The extra current boosts torque to handle the load. This adjustment keeps the motor running smoothly.

Here’s a table showing how Back EMF and torque work together:

Parameter | What It Shows |

|---|---|

Back EMF | How magnetic fields and temperature affect motor performance. |

Torque | How torque changes with different magnet setups and temperatures. |

Temperature Variations | How Back EMF and torque respond to 20 °C, 85 °C, and 150 °C. |

This table shows how Back EMF helps the motor adapt to changes in load and temperature.

Contribution to Energy Efficiency and Stability

Back EMF makes motors more energy-efficient. It pushes back against voltage, lowering the current as speed increases. This means the motor only uses the energy it needs, reducing waste and heat.

Back EMF also keeps the motor steady. It helps the motor stay at the same speed, even if the load changes. This is important for things like haptic systems, where steady vibrations are needed. Back EMF ensures smooth operation, better performance, and a longer motor life.

Benefits of Back EMF in Enhancing Performance

Smoother and More Stable Motor Operation

Back EMF helps motors run smoothly and stay steady. As the motor spins, it controls the current flow. This stops sudden speed changes and reduces vibrations. Even with different loads, the motor works consistently. For example, when starting, back EMF slows down speed changes. This helps the motor reach a steady speed faster.

Here’s a table showing how back EMF improves motor stability:

Evidence Description | Findings |

|---|---|

EKF used for back EMF estimation | Reduces speed changes and improves current use. |

Adjusting electrical angle frequency | Lowers speed changes and boosts current efficiency. |

Adding damping torque component | Cuts speed changes during the start process. |

These benefits make back EMF important for devices needing steady motors, like wearables with haptic feedback.

Improved Control and Responsiveness

Back EMF helps control motors and react to changes better. It works like feedback, adjusting current based on motor speed. If the motor has a heavier load, back EMF lowers. This lets more current flow, increasing torque. The motor adjusts quickly without needing help.

For example, in phones or game controllers, back EMF keeps vibrations smooth. It adapts instantly to changes, giving steady and responsive feedback. This makes the motor work better and feel consistent.

Reduced Power Consumption and Heat Generation

Back EMF saves energy by limiting current as speed increases. This lowers power use and stops extra heat from building up. At high speeds, back EMF pushes against voltage. This ensures the motor only uses needed energy. It also reduces wear, making the motor last longer.

This means devices stay cooler and work longer. Whether it’s a fitness tracker or medical tool, back EMF helps save energy. It makes devices more reliable and better for long-term use.

Practical Uses of Back EMF in ERM Motors

Everyday Gadgets and Wearables

ERM motors are found in gadgets like phones and smartwatches. Back EMF helps these devices vibrate smoothly and steadily. For example, when your smartwatch buzzes, Back EMF keeps the vibration even. It also saves energy, which is important for battery life. By using less power, Back EMF makes wearables last longer and work better.

Car Haptic Feedback Systems

Cars use haptic systems to improve driving. These systems make steering wheels or seats vibrate for alerts. Back EMF ensures these vibrations are clear and quick. For example, if your car warns you about lane drifting, Back EMF helps you feel the vibration clearly. It also saves energy, which is very important for electric cars.

Tools and Medical Equipment

Back EMF is important in tools and medical devices. In factories, it helps machines vibrate steadily, reducing wear. In medical tools, it keeps vibrations smooth for accurate results. This is important for patient comfort and safety. Back EMF also stops devices from overheating, helping them last longer in critical jobs.

Knowing back EMF helps ERM vibration motors work better. It acts like a built-in controller, making motors run smoother and use less energy. Back EMF pushes against the voltage you give the motor. This reduces extra current, saving power and stopping overheating.

Here’s a simple table showing how back EMF affects motors:

Feature | What It Means |

|---|---|

Torque | More back EMF usually means less torque at the same voltage. |

Speed | Higher back EMF makes the motor spin faster. |

Efficiency | Back EMF controls current to stop wasting energy. |

Using back EMF helps devices like wearables and tools work well. It makes motors last longer and perform steadily in many situations.

FAQ

Why is back EMF important for ERM vibration motors?

Back EMF helps the motor keep a steady speed and torque. It stops energy waste and keeps the motor from overheating. Without it, the motor would use more power and wear out quickly. Back EMF makes the motor run smoother and last longer.

Why does back EMF increase with motor speed?

When the motor spins faster, the magnetic field changes more. These changes create stronger back EMF. This helps the motor use less current and stay efficient at high speeds.

Why does back EMF improve energy efficiency?

Back EMF pushes against the voltage, lowering extra current flow. This means the motor only uses the energy it needs. Using less power creates less heat and makes batteries last longer.

Why do wearables rely on back EMF for vibration control?

Back EMF keeps vibrations steady in devices like smartwatches. It adjusts the motor’s current to match speed changes. This makes vibrations smooth, improves user experience, and saves battery life.

Why should you optimize back EMF in motors?

Optimizing back EMF makes motors work better. It keeps them stable, saves energy, and stops overheating. For haptic systems or medical tools, it ensures motors are reliable and efficient.

See Also

Understanding Motor Brushes: Key Elements for ERM Vibration Efficiency

Exploring Motor Diagrams: Types, Uses, and Key Components

Resonant Systems Explained: Impact on Vibration Motor Efficiency

Battery-Powered Motors: Varieties, Uses, and Power Efficiency Insights

Maintaining Electric Vibration Motors: Tips for Longevity and Efficiency

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry