Top Methods to Analyze and Solve Motor Vibration Problems

Motor vibration causes big problems in industries. It can break machines, stop work, and cost money. When motors fail without warning, it delays production and may lead to fines. For example:

Important machine failures raise repair costs and slow down work.

Many industries lose a lot of money from sudden shutdowns.

Fixing problems early has saved companies up to $16 million in lost profits.

By fixing motor vibration early, you can avoid delays and keep things running smoothly.

Key Takeaways

Checking motors often stops vibration problems. Look for loose bolts, old bearings, or parts not lined up to avoid expensive fixes.

Vibration tools can find issues early. Tools like VIBGUARD and VIBSCANNER check motor health and stop breakdowns.

Fixing misalignment with accurate tools is important. Use laser alignment systems to make sure shafts and couplings fit correctly.

Balancing spinning parts lowers vibrations. Find unbalanced pieces and use balancing methods to make motors work better.

Predictive maintenance saves time and money. Watch vibrations regularly and plan fixes to stop sudden shutdowns.

Common Causes of Motor Vibration

Mechanical Imbalances in Rotating Components

When parts like rotors have uneven weight, they wobble. This wobbling causes vibrations during spinning. You might notice strange noises or shaking. Special tools can balance these parts to stop vibrations. Checking these parts often helps avoid bigger problems.

Misalignment of Shafts or Couplings

If shafts or couplings don’t line up, motors vibrate. This misalignment slows the motor and reduces power. It also changes vibration patterns, which can show the problem. Bad misalignment can break parts like bearings. Tools for alignment can fix this and make the motor run smoothly again.

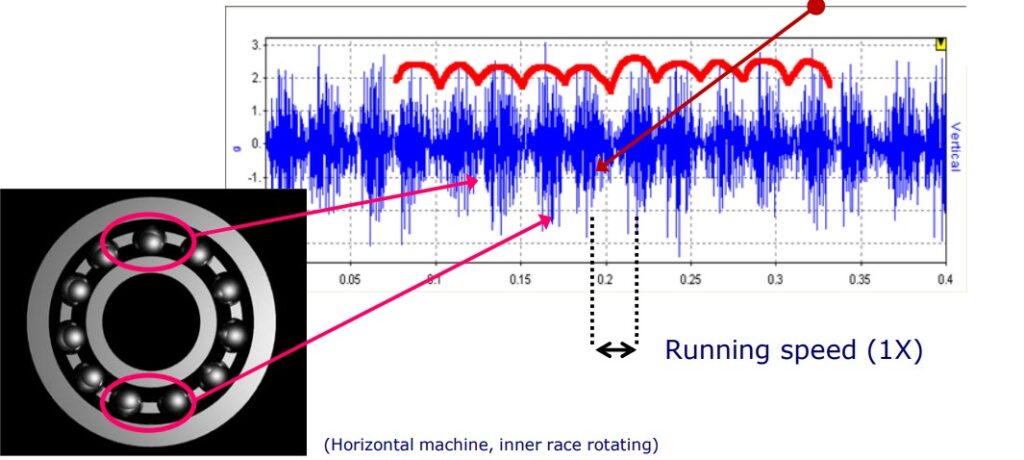

Bearing Wear and Damage

Bearings help parts spin smoothly, but they wear out. Worn bearings can make noise, overheat, or lower efficiency. This wear increases vibrations in the motor. Replacing or oiling bearings keeps them working well. Watching for early wear saves money on repairs.

Electrical Causes (e.g., Rotor Bar Defects, Air Gap Variations)

Electrical problems can make motors vibrate a lot. Issues like rotor bar defects or air gap variations often go unnoticed until damage happens. You can find these problems by learning their effects and using special tools.

Rotor Bar Defects: Broken rotor bars mess up the motor's magnetic field. This causes uneven spinning and vibrations. Overheating or stress often breaks these bars. Tools like current analysis and the Hilbert transform can spot these problems early.

Air Gap Variations: An uneven space between the rotor and stator creates imbalance. This imbalance makes the motor vibrate more and work less efficiently. Finding air gap issues is tricky, but regular checks and accurate measurements can help fix them.

By solving these electrical problems, you can avoid damage and keep motors reliable.

Improper Mounting and External Vibrations

Bad mounting and outside vibrations often cause motor problems. If a motor isn’t mounted well, it can move during use and become unstable. Vibrations from nearby machines can also affect the motor and make things worse.

Watch for these signs:

Stronger vibrations or unusual vibration patterns.

Loud noises that happen with vibrations.

Loose mounts or shaky foundations that make the motor unstable.

To fix this, mount the motor on a solid, flat surface. Use pads or mounts to block outside vibrations. Check the motor’s base and nearby machines often to find problems. Fixing these issues lowers vibrations and helps the motor work better.

Methods to Analyze Motor Vibration

Using Vibration Monitoring Tools

Vibration tools help find motor problems early. These tools detect unusual vibrations, like bad lubrication or worn bearings, before they cause damage. In the past, people checked vibrations manually. Now, advanced systems monitor motors all the time. These systems track motor health and let you fix issues quickly.

Here are some useful tools for vibration monitoring:

VIBGUARD IIoT: Tracks important machines online.

VIBSCANNER 2: A handheld tool for quick checks.

VIBXPERT II and III: Finds detailed vibration problems.

These tools keep motors working well and prevent breakdowns. Regular checks make sure machines run smoothly and avoid sudden failures.

Conducting Frequency Analysis

Frequency analysis helps understand motor vibration better. It changes vibration signals into frequencies to find the problem's source. This method is great for spotting unbalanced parts, misaligned shafts, or gear issues.

Steps for frequency analysis:

Use Fast Fourier Transform (FFT) to change the signal.

Find key frequencies causing the vibration.

Study patterns to check for weak spots or possible failures.

For example, a global level vibration meter measures all vibrations. Adding a filter focuses on important parts for better results. Frequency analyzers use small filters for detailed checks, making them great for tough problems.

Frequency analysis shows how motors behave. This helps fix problems and improve motor performance.

Selecting Appropriate Sensors and Transducers

Picking the right sensor is key for good vibration checks. Each sensor works best in certain situations. Choose based on what you need to measure.

Sensor Type | Advantages | Disadvantages |

|---|---|---|

Displacement Sensor | Good for slow vibrations | Not good for fast vibrations |

Velocity Sensor | Best for medium-speed vibrations | Limited for very slow or very fast ones |

Accelerometer | Works for many vibration speeds | Not great for very slow vibrations (<3Hz) |

Accelerometers are the most common choice. They work for many vibration types and speeds. But for slow vibrations, displacement sensors might be better.

Think about the motor’s conditions and what you need to measure. The right sensor gives accurate data to solve motor vibration problems.

Performing Visual Inspections and Physical Testing

Looking at the motor and testing it can help find problems. These simple methods show signs of wear, damage, or misalignment early. Fixing these issues quickly can save money and time.

Steps for Visual Inspections:

Check the Motor’s Outside: Look for loose bolts or cracked parts. Worn-out pieces can make the motor shake more.

Look for Leaks: Oil or grease leaks near bearings or seals may mean wear or bad lubrication.

Inspect Electrical Parts: Loose or rusty connections can cause uneven motor vibrations.

Watch the Motor Run: Look for strange movements, shaking, or noises while it works.

Physical Testing Techniques:

Feel for Vibrations: Touch the motor to sense unusual shaking. This quick test shows areas needing more checks.

Check Temperatures: Use a heat gun to find overheating, which often links to vibration problems.

Test Shaft Alignment: Use a ruler or laser tool to check if shafts are straight.

Tip: Always turn off and lock the motor for safety before checking it. Only watch it run when it’s safe to do so.

By combining looking and testing, you can find motor problems early. Fixing them fast stops bigger issues later.

Using Predictive Maintenance Techniques

Predictive maintenance uses tools and data to stop problems before they happen. This smart method saves time and money by avoiding sudden motor failures.

Main Predictive Maintenance Methods:

Vibration Checks: Use tools to track motor vibrations. These tools find patterns showing wear or imbalance.

Heat Imaging: Special cameras find hot spots from friction or electrical issues. Fixing these stops overheating and vibrations.

Ultrasound Testing: High-pitched sound tools find bearing wear or lubrication problems causing vibrations.

Data Tracking: Study data over time to see when parts might fail. This helps plan repairs early.

Why Predictive Maintenance Helps:

Less Downtime: Fixing problems early stops sudden shutdowns.

Save Money: Avoiding emergency fixes lowers repair costs.

Longer Motor Life: Regular checks keep motors working well for years.

Note: Predictive maintenance needs tools and training at first. But the long-term savings make it worth it.

Using predictive maintenance keeps motors running smoothly. It helps avoid problems and keeps work moving without delays.

How to Solve Motor Vibration Problems

Regular Maintenance and Inspection Practices

Regular maintenance helps reduce motor vibration and keeps it reliable. By checking motors often, you can find problems like misalignment or wear early. Maintenance also improves lubrication, which lowers vibration levels.

Key Benefits of Regular Maintenance:

Improved Reliability: Regular checks stop problems like misaligned shafts or worn bearings.

Reduced Vibration Levels: Monitoring helps fix issues early, reducing vibrations.

Longer Equipment Life: Good lubrication and repairs make motors last longer.

Evidence Description | Impact on Vibration Reduction |

|---|---|

Regular maintenance improves reliability and prevents chronic problems. | Fewer issues like imbalance and misalignment. |

Past reviews show training needs and fixes for better results. | Better lubrication and more reliable equipment. |

Monitoring finds problems early for quick maintenance. | Helps lower motor vibration levels. |

Tip: Make a schedule for inspections, lubrication, and vibration checks. This keeps your motor working well.

Correcting Misalignment with Precision Tools

Misaligned shafts or couplings often cause motor vibration. Precision tools help align these parts correctly, reducing stress and improving performance.

Steps to Correct Misalignment:

Find Misalignment: Use tools like vibration analyzers or laser alignment systems.

Fix the Problem: Adjust shafts and couplings with tools like dial indicators or lasers.

Check the Fix: Run the motor and see if vibrations are gone.

Tools for Shaft Alignment:

Dial Indicators: Check shaft positions and find angular misalignment.

Laser Alignment Systems: Give accurate readings and make alignment easier.

Note: Misalignment can damage bearings and couplings. Fix it early to avoid expensive repairs.

Balancing Rotating Components

Unbalanced parts, like rotors, cause motor vibration. Balancing these parts makes the motor run smoothly and last longer.

Types of Unbalance and Balancing Techniques:

Type of Unbalance | Description | Balancing Technique(s) |

|---|---|---|

Static Unbalance | Shaft axis and inertia axis are parallel. | 1. Add weight opposite the unbalance. 2. Balance weight at both rotor ends. |

Coupled Unbalance | Inertia axis crosses center of gravity but isn’t parallel. | Add weight in the same plane at both ends, 180° apart. |

Quasi Static Unbalance | Inertia axis crosses shaft axis but not at the center of gravity. | Fix it like coupled unbalance. |

Dynamic Unbalance | Inertia axis crosses both center of gravity and shaft axis. | Add weight in at least two planes. |

Steps to Balance Rotating Components:

Find the Problem: Use balancing machines or vibration tools to detect unbalance.

Fix the Balance: Add or remove weight based on the type of unbalance.

Test the Motor: Run the motor and check if vibrations are reduced.

Tip: Use balancing machines for accurate fixes, especially for tricky problems.

Replacing or Repairing Bearings

Bearings are important for keeping motors steady and quiet. When bearings wear out, they can cause loud noises, overheating, and more shaking. Fixing or replacing them quickly keeps the motor running well and avoids bigger problems.

Signs of Bearing Problems:

Strange sounds like grinding or squeaking.

Too much heat near the bearing area.

Worn-out or broken parts seen during checks.

Steps to Replace or Repair Bearings:

Find the Problem: Use tools to check for noise or shaking from bearings.

Take Out the Old Bearing: Turn off the motor and take it apart safely. Use special tools to remove the bad bearing.

Clean and Check: Look for damage or dirt on the shaft and housing. Clean everything before adding a new bearing.

Put in the New Bearing: Place the new bearing carefully and align it properly. Use a tool to secure it without breaking it.

Add Lubrication: Use the right oil or grease to make the bearing last longer.

Tip: Lubricating bearings often stops them from breaking and lowers vibration. Bearings that are cared for can last longer than the motor.

If vibration isn’t fixed, bearings wear out faster. Fixing these problems early stops damage, noise, and safety risks.

Installing Anti-Vibration Mounts and Isolation Pads

Anti-vibration mounts and pads help stop outside shaking from affecting motors. These tools keep the motor steady and stop vibrations from spreading to other machines.

Benefits of Anti-Vibration Mounts:

Less shaking makes motors work better.

Quieter motors improve the workspace.

Stable motors protect nearby machines from damage.

How to Install Anti-Vibration Mounts:

Pick the Right Mounts: Choose mounts that match the motor’s size and weight.

Prepare the Area: Make sure the motor’s base is flat and clean. Uneven spots make mounts less effective.

Attach the Mounts: Bolt or stick the mounts to the motor’s base. Follow the instructions for proper setup.

Test the Motor: Run the motor and check for shaking. Adjust the mounts if needed for better stability.

Isolation pads also help by soaking up vibrations. Put these pads under the motor to protect the floor and nearby machines.

Note: Check mounts and pads often for damage. Replace them when needed to keep vibrations under control.

Addressing Electrical Issues with Diagnostics

Electrical problems can make motors shake. Things like broken rotor bars or uneven air gaps mess up the motor’s magnetic field. Using diagnostics helps find and fix these issues.

Common Electrical Issues:

Rotor Bar Defects: Broken rotor bars cause imbalance and shaking.

Air Gap Variations: Uneven gaps between the rotor and stator lower efficiency.

Steps to Diagnose Electrical Problems:

Check Vibration Data: Use tools to measure how much and how fast the motor shakes. For example, a pump motor with 0.449 in/sec Peak at 29.75 Hz may have rotor bar issues.

Analyze Current: Look at the motor’s electrical current for problems. A reading of 29.83 amps below 45 dB amps suggests rotor bar trouble.

Measure the Air Gap: Use tools to check the space between the rotor and stator. Look for uneven gaps or wear.

Fix or Replace Parts: Repair broken rotor bars or adjust the air gap to balance the motor.

Tip: Regular checks stop electrical problems from getting worse. Fixing them early reduces shaking and keeps the motor reliable.

Diagnostics give helpful details about motor health. Fixing these problems keeps the motor running smoothly and lasting longer.

Importance of Proactive Vibration Management

Extending Equipment Lifespan

Managing vibration early helps your equipment last longer. Watching for motor vibration stops damage to important parts. Balanced rotors and aligned shafts lower stress on bearings. This keeps motors working well for many years.

Regular checks and fixes are also important. Look for loose bolts, worn bearings, or misaligned parts. Fixing small problems early avoids costly repairs later. Tools like vibration analyzers help find issues quickly. Motors with less vibration last longer and work better.

Tip: Check for vibration problems every month. This simple habit saves money on repairs.

Enhancing Operational Efficiency

Fixing motor vibration makes your equipment work better. Vibrations waste energy by causing heat and friction. Solving these problems helps motors use energy more efficiently. This lowers electricity costs.

Efficient motors give steady power. This means fewer work delays and better results. For example, a motor with little vibration powers machines smoothly. This keeps your work running without interruptions.

Note: Vibration tools may cost more at first. But they save money by improving energy use and efficiency.

Minimizing Downtime and Repair Costs

Unexpected breakdowns stop work and cost money. Managing vibration early avoids these problems. Finding issues like misaligned shafts early stops bigger damage.

Fixing a broken motor costs more than regular maintenance. Solving vibration problems quickly avoids emergency repairs. This saves money and keeps your equipment ready when needed.

Tip: Use predictive maintenance to track vibrations. Plan repairs during scheduled downtime to avoid surprises.

Improving Workplace Safety

Motor vibration can harm both machines and workers. Fixing vibration problems makes the workplace safer and lowers accident risks.

How Motor Vibration Affects Safety

Too much vibration can loosen bolts and break parts. This can cause falling objects, machine failures, or even fires from overheating. Vibrating motors also make loud noises that can hurt workers' hearing over time.

Tip: Check vibration levels often to stop dangers early.

Steps to Improve Workplace Safety

Check Equipment Often

Look for loose bolts, cracks, or worn-out bearings. These problems can lead to sudden failures and hurt workers. Use tools to find hidden issues before they get worse.Add Safety Guards

Put guards around motors and moving parts. These guards protect workers from flying pieces if something breaks.Lower Noise Levels

Vibrating motors are noisy. Use mounts and pads to reduce noise. If it’s still loud, give workers ear protection.Teach Workers

Show workers how to spot signs of vibration, like strange noises or shaking. Tell them to report problems right away.Stick to Maintenance Plans

Follow a regular maintenance schedule. Lubricate parts, check alignment, and replace worn pieces to keep motors safe.

Why Safety Matters

A safe workplace helps workers feel confident and work better. When equipment is cared for, risks are lower, and operations run smoothly. Managing motor vibration protects your team and keeps everything on track.

Remember: Safety means more than rules—it’s about keeping everyone safe and comfortable.

Motor vibration can be handled with the right steps. Finding the causes and solving problems helps machines work better. Managing vibration early brings big benefits like less downtime, longer machine life, and better performance.

For instance, smart systems use sensors to check vibration and heat. These tools warn you about problems before they get worse. Fixing issues early stops expensive repairs and sudden breakdowns. In power plants, these systems have delayed big expenses, saving lots of money.

Benefit | Improvement Percentage |

|---|---|

Less Downtime | |

Longer Machine Life | 20–40% |

Using smart plans keeps machines running well, lowers risks, and helps businesses succeed for years.

FAQ

What are the first signs of motor vibration problems?

You may hear strange noises, feel heat, or see shaking. These signs often mean misalignment, unbalanced parts, or worn bearings. Regular checks can help find these issues early.

How often should you check for motor vibration?

Check motors every month or during planned maintenance. Using tools like vibration analyzers often helps find problems before they get worse.

Can improper lubrication cause motor vibration?

Yes, bad lubrication causes friction, overheating, and shaking. Use the right lubricant and amount to keep parts working smoothly.

What tools are best for diagnosing motor vibration?

Vibration analyzers, laser alignment tools, and accelerometers work well. These tools find problems like misalignment, unbalance, or worn bearings.

Tip: Use these tools with visual checks for better results.

How do anti-vibration mounts help?

Anti-vibration mounts reduce shaking and absorb shocks. They keep motors steady, protect nearby machines, and lower noise. Place them on a clean, flat surface for the best results.

Emoji Reminder: 🛠️ Check mounts often to keep them working well.

See Also

Exploring Various Techniques for Measuring Vibrations Effectively

A Comprehensive Overview of Vibration Motors and Their Uses

An In-Depth Resource for Accurate Vibration Measurement

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry