How 5V Electric Motors Power Modern Electronics: Efficiency, Performance, and Design Considerations

When you use gadgets like phones or smart home tools, you might not notice how 5V electric motors help them work. These motors provide just the right amount of power for small tasks, ensuring your devices operate smoothly. Their low voltage consumes less energy, which is better for the environment. Additionally, they function steadily, making your devices reliable and efficient every day.

Key Takeaways

5V electric motors save energy by using low voltage. This helps devices work while being better for the environment.

Changing motor speed with Variable Frequency Drives (VFDs) saves more energy in many uses.

Keeping motors clean and cool makes them last longer. It also stops overheating and other problems.

Picking the right motor for the job, like for speed or strength, helps devices work better.

Strong materials make motors tougher and need fewer repairs. This keeps them working well for a long time.

How to Achieve Efficiency with 5V Electric Motors

Optimizing Energy Use

To save energy, focus on how the motor works with its power system. A good design makes sure the motor uses only what it needs. This reduces waste and boosts efficiency. For example, Variable Frequency Drives (VFDs) help control motor speed and torque. They adjust the motor to match the actual work needed, cutting down extra energy use.

This method has improved efficiency in real-world examples. Pumping systems with VFDs change pump speeds to match water flow. This removes the need for throttling valves and lowers wear. HVAC systems also adjust fan and compressor speeds for better heating and cooling. These examples show how smart power designs can make energy use more efficient and eco-friendly.

Supporting Sustainability

Using 5V electric motors helps the planet by saving energy and lowering environmental harm. These motors use low voltage, which needs less energy than higher-voltage ones. This makes them perfect for devices that need efficient power without losing performance.

Many industries use these motors for their green benefits. Conveyor systems use VFDs for smooth starts and exact speed changes, saving energy. Cranes and hoists use careful control for lifting, making them safer and less power-hungry. Adding 5V motors to modern devices supports energy savings and eco-friendly habits.

Improving Efficiency with Smart Controls

Smart controls can make 5V motors work even better. Techniques like pulse-width modulation (PWM) and closed-loop systems help a lot. PWM switches the motor’s power on and off quickly to control speed and torque. Closed-loop systems watch the motor’s work and adjust it for best performance.

Industries use these methods to improve motor efficiency. Machine tools adjust spindle speeds to make better products and last longer. Extruders and mixers keep steady torque and speed for even results. In tough places like mines, controlled motor use improves reliability and saves energy.

Application | How Efficiency Improves |

|---|---|

Pumping systems | VFDs match pump speeds to flow needs, reducing wear and skipping throttling valves. |

HVAC systems | Adjusts fan and compressor speeds for better heating and cooling. |

Conveyor systems | Smooth starts and exact speed changes save energy and fit different loads. |

Cranes and hoists | Careful control makes lifting safer and uses less power. |

Machine tools | Changes spindle speeds for better products and longer tool life. |

Extruders and mixers | Keeps torque and speed steady for even results in factories. |

Mining and quarrying | Uses VFDs for controlled work in tough conditions, saving energy. |

Energy savings | VFDs cut energy use by matching power to actual needs, saving a lot. |

By using these smart methods, 5V motors can give reliable power while staying efficient in many uses.

How to Maximize Performance of 5V Electric Motors

Improving Speed and Torque

To make a 5V electric motor work its best, focus on its speed and torque. Speed shows how fast it spins, and torque is its turning strength. Both are important for different tasks.

Pick the right motor for your device. A small motor made for fast spinning works well in fans or drones. For stronger tasks like robotic arms or small conveyor belts, choose one with more torque.

You can also improve speed and torque by adjusting the power supply. A steady 5V power source gives stable energy. This avoids drops that can hurt performance. Adding gears can help too. Gears let you swap speed for torque or the other way around, depending on what you need.

Tip: Don’t overload the motor. Too much load slows it down and wears it out. Keep the load within its limit for better results.

Ensuring Reliability in Operation

A reliable motor is key, especially for devices that run often or do important jobs. To keep your 5V motor reliable, take care of it and use it properly.

First, keep it clean. Dust and dirt can block parts and lower performance. Use a soft brush or air to clean it often.

Second, watch its temperature. If it gets too hot, it can break inside and not last long. Make sure it has good airflow to stay cool. In hot places, add a cooling system if needed.

Lastly, use strong parts. Good materials make the motor last longer. For example, stainless steel ball bearings reduce friction and wear.

Note: A reliable motor works better and saves money on repairs and downtime.

Adapting Motors for Diverse Applications

5V motors can power many devices. To get the most out of them, match them to the job.

For light devices like drones or small robots, pick a small, efficient motor. It gives enough power without adding extra weight. For tools like drills or mixers, choose a motor with more torque and strength.

You can also change the motor’s controls. A programmable controller lets you set speed, torque, and direction for each task. For example, in automated systems, you can program it to repeat tasks perfectly.

Example: In a smart home, a 5V motor can move blinds up and down. With a sensor, it adjusts blinds based on sunlight, saving energy at home.

By customizing the motor for your needs, you can make it work better while staying efficient and reliable.

Key Design Considerations for 5V Electric Motors

Small and Lightweight Design

When using 5V electric motors, focus on keeping them small and light. These motors are great for gadgets where space is tight or portability matters. Their tiny size and low weight make them easy to fit into modern devices without losing power.

Here’s a simple look at what makes these motors useful:

Feature | What It Means |

|---|---|

Small size | Fits in tight spaces. |

Lightweight | Easy to carry and handle. |

Strong torque | Gives good power in a small motor. |

Quiet operation | Runs quietly for better user comfort. |

Choosing motors with these features helps save energy and boosts efficiency. Small designs also let heat escape better, keeping the motor cool and working well.

Picking Strong Materials

The materials in your motor affect how long it lasts and works. Strong materials like stainless steel or tough aluminum handle wear and tear well. For example, stainless steel bearings lower friction, saving energy and making the motor last longer.

Think about materials that won’t rust, especially if the motor will be outside or in wet places. Using good materials makes the motor stronger and cuts down on repairs. This way, your motor stays powerful and reliable for a long time.

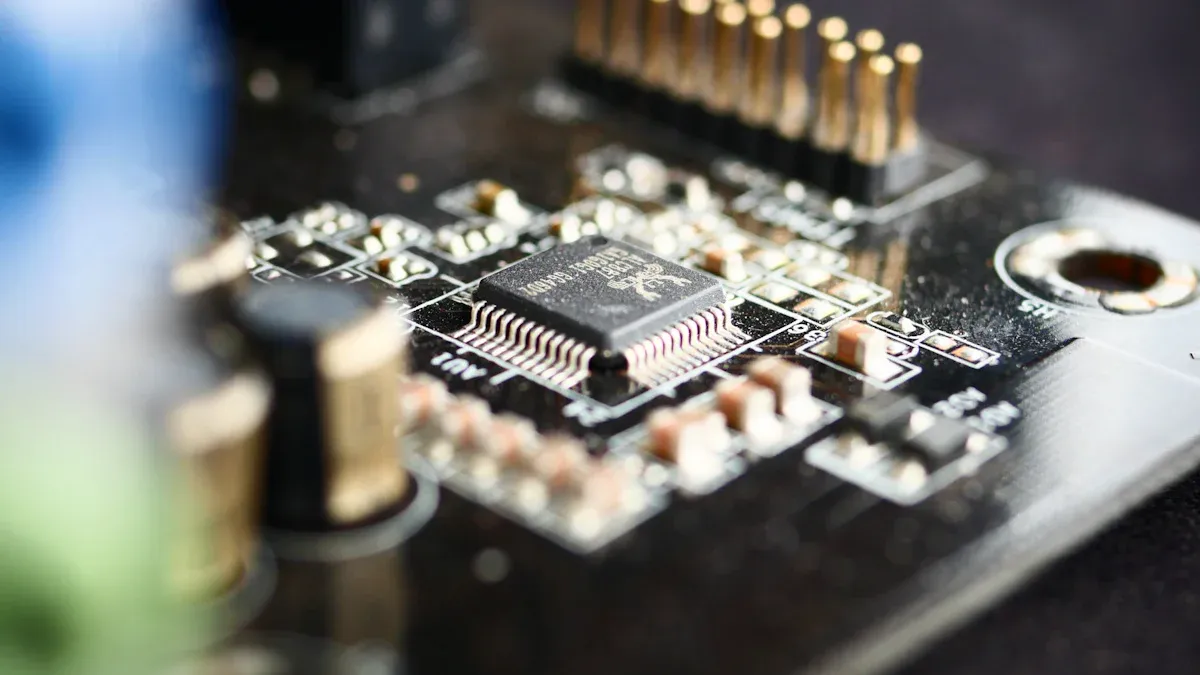

Connecting Motors to Electronics

To get the best from 5V motors, connect them properly to your electronics. First, make sure the motor’s power matches the system’s needs. A steady 5V power source stops problems like power drops that can hurt the motor.

You can also use smart controls, like microcontrollers, to adjust speed and torque. These controls help the motor do specific jobs better and save energy. For example, in robots, good motor control makes movements smoother and tasks easier.

Good connections also stop energy waste. Use quality wires and connectors to move power efficiently. This keeps the motor cool and running well. By focusing on good connections, your motor will work better with the rest of your system.

5V electric motors are important for running today’s electronics. Using them efficiently helps save energy and protect the environment. Better performance makes devices work dependably, and smart designs keep motors small, strong, and simple to use.

Key Takeaway: These motors help create smarter, greener, and more useful devices.

In the future, they could change robotics, IoT, and renewable energy. Learning how they work can open up new ways to innovate.

FAQ

Why are 5V electric motors good for modern gadgets?

They use low voltage, saving energy and fitting small devices. These motors work well with electronics, giving steady performance in tight spaces. Their light and simple designs suit portable tools perfectly.

How can you install a 5V electric motor correctly?

Follow the maker’s instructions. Use good connectors to stop power loss. Attach the motor tightly to reduce shaking. Make sure the power supply fits the motor’s needs, like using stable power sources.

Can 5V electric motors handle tough jobs?

Yes, they can. With changes like adding gears or smart controls, they work great. They are strong and can handle many tasks, from robots to small machines.

Why are simple designs helpful for 5V electric motors?

Simple designs make setup and fixing easier. You can swap or upgrade parts without changing the whole motor. This saves time and money.

How do 5V electric motors save energy?

They use smart controls like pulse-width modulation to use power wisely. This makes sure they only use energy when needed, cutting waste and boosting efficiency.

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry