5 Quick Steps to Connect 3V DC Motor Safely

You want to connect a 3 v dc motor to a battery with safety in mind. Using the right dc motor and following instructions matters. INEED motors help you avoid common issues like overloads, bad installation, or skipping instructions. Many beginners use the wrong battery, which can burn out your motor or drain power too fast.

The most common causes of damage include:

Overloading motor windings

Improper installation

Ignoring manufacturer’s instructions

Mistake Description | Implication |

|---|---|

Using a 9V battery on a 3V motor | Motor can fuse or spin too fast, leading to quick depletion or failure |

Key Takeaways

Always match the battery voltage to your 3V DC motor. Using the wrong voltage can damage the motor or cause it to fail.

Secure all connections to prevent overheating and fire risks. Loose wires can lead to dangerous situations.

Regularly monitor your motor during operation. Look for unusual noises or heat to catch potential issues early.

Gather Materials

Essential Items

Before you start connecting your 3V DC motor, you need to gather a few key items. Here’s a quick checklist to help you get ready:

3V DC motor

Battery (make sure it matches the motor’s voltage)

Wires with secure connectors

Switch for easy control

Voltage converter (if your battery is higher than 3V)

Large electrolytic capacitor to stabilize your dc power supply

Soldering iron or tape for strong connections

You want to make sure your battery can deliver enough current for your motor. If you use a battery with too little capacity, your motor might not run smoothly or could stop suddenly. Motors also draw more current when they start, so keep that in mind when choosing your battery.

Tip: Always double-check the voltage and current ratings before you connect anything. Using the right dc power supply helps prevent damage and keeps your project safe.

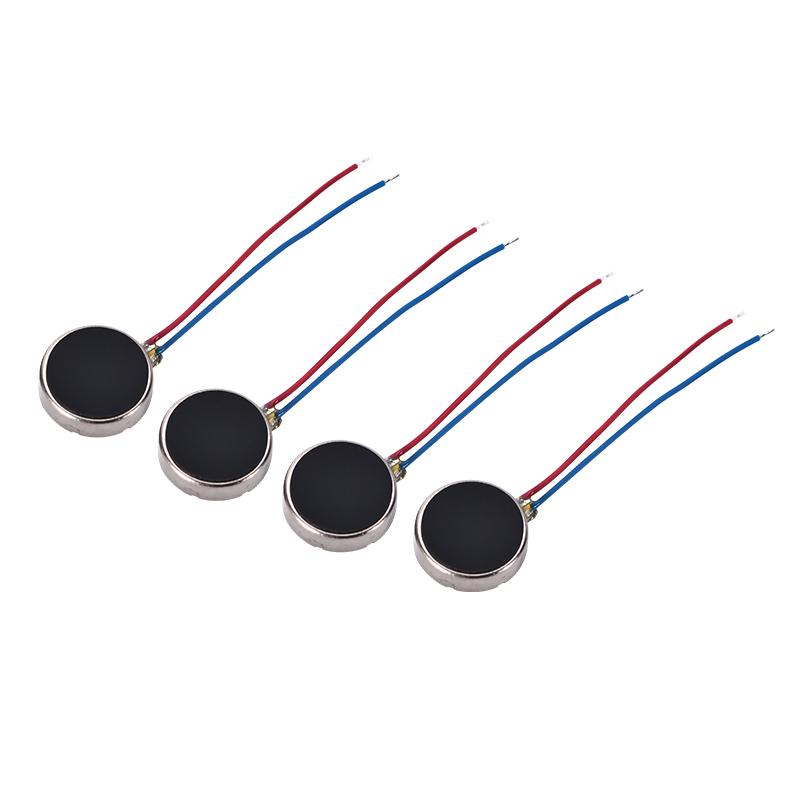

INEED Coin Brushless BLDC Vibration Motors

If you want a motor that lasts and runs efficiently, INEED Coin Brushless BLDC Vibration Motors are a great choice. These motors use electronic commutation, so you don’t have to worry about brush wear. You get quieter operation, less heat, and lower electromagnetic interference. Brushless motors can last up to ten times longer than traditional brushed motors.

INEED Coin vibration motors

INEED Coin vibration motors work well for lightweight devices. They offer stable performance and fit into small spaces. You can use them for wearables or medical devices where reliability matters.

INEED Brushed Coreless motors

INEED Brushed Coreless motors give you a compact option for projects that don’t need brushless technology. They’re easy to set up and work for simple applications.

Factor | Description |

|---|---|

Torque Requirements | Make sure your motor can handle the job’s demands. |

Feedback Handling | Smooth feedback is important, especially at high speeds. |

Manufacturer Compatibility | Using parts from the same brand makes setup easier. |

Duty Cycle | Decide if your motor will run all the time or just sometimes. |

Efficiency and Energy Use | Efficient motors save battery life. |

Environment and Conditions | Think about where you’ll use your motor. |

Noise and Vibration Levels | Brushless motors are quieter for sensitive projects. |

Inspect 3V DC Motor & Battery

Check for Damage

Before you connect anything, take a close look at your 3 v dc motor and battery. You want to make sure both parts are in good shape. Damaged components can cause problems or even stop your project before it starts. Here’s what you should look for:

Swelling on the battery casing

Any signs of leakage

Corrosion around the terminals

If you spot any of these issues, do not use that part. Using damaged items can lead to short circuits or poor performance. Always choose clean, undamaged components for the best results.

Verify Voltage

Now, check the voltage on your battery. You want the battery’s voltage to match the rating on your motor. For a 3 v dc motor, a battery with a 3V rating works best. If you use a battery with a higher voltage, only do so for a short time. A small increase, about 20-25% above 3V, is usually safe for brief testing. Going above this range can make the motor overheat or wear out faster.

Tip: Use a simple voltmeter to check your battery’s voltage before connecting it. This step helps you avoid surprises and keeps your dc motor running smoothly.

Matching the right voltage keeps your project safe and helps your motor last longer. Take your time with this step, and you’ll set yourself up for success.

Connect Wires to Battery

Secure Connections

You want every connection to be solid when you wire up your 3 v dc motor. Loose wires can cause trouble, like overheating or even a fire risk. Here’s a simple way to make sure your setup is safe:

Turn off your dc power supply before you start. Safety first!

Inspect your wires. Look for any damage or exposed metal.

Use the right wire gauge for your motor’s current. Thin wires can overheat.

Attach the positive wire from your battery to the positive terminal on the motor. Tighten it so it doesn’t wiggle.

Connect the negative wire to the negative terminal. Make sure it’s snug.

Cover any exposed metal with electrical tape or heat shrink tubing.

Tip: If you want easy control, add a switch between your battery and motor. This lets you turn the motor on and off without disconnecting wires.

Loose connections can increase resistance and cause local heating. That heating can melt the junction and create a fire hazard. Always double-check your work before you connect batteries.

You can wire batteries in series connection for higher voltage or wire batteries in parallel connection for more current. Just make sure your total voltage matches your motor’s rating.

Polarity Check

Polarity matters every time you connect a dc motor. If you reverse the polarity, your motor will spin the other way. Sometimes, reversed polarity can cause erratic behavior or even damage your motor.

Impact of Incorrect Polarity | Description |

|---|---|

Direction Reversal | The motor runs in the opposite direction when polarity is reversed. |

Erratic Behavior | The motor may behave unpredictably if connected to incompatible circuitry. |

Potential Damage | Reversed polarity can damage the motor or speed controller if not designed to handle it. |

Always check the voltage and polarity before you connect batteries. If you use a switch, connect one wire from the battery holder to the switch, then from the switch to the motor. Make sure your switch can handle the voltage and current. You can add a capacitor in parallel connection with the switch to protect against voltage spikes.

Test Motor with Batteries

Safety Precautions

You want to keep safety first when you test your 3 v dc motor with batteries. Before you start, check your dc power supply and make sure your wires are secure. Use only one hand to hold the probes if you measure voltage or current. This simple trick lowers your risk of shock. Always inspect the insulation on your probes. If you see cracks or wear, swap them out. Spring clips help keep probes in place, so you don’t have to hold them. Treat your meter leads with care, just like the meter itself. Never use homemade probes. When you connect batteries, check for both AC and DC voltage. Sometimes, circuits surprise you.

Tip: Always check every pair of points in your series and parallel connections for hazardous voltage before you power up.

Avoid Short Circuits

Short circuits can ruin your project. Sparks may start fires, and exposed wires can cause electrocution. You want to avoid these risks. Inspect your motor and wires before you connect batteries. Install protective devices if you can. Clean and maintain your setup often. If you wire batteries in series or parallel, double-check every connection. A short circuit can shut down your equipment and damage your motor. You want your current to flow smoothly, not jump across a broken wire.

Here’s a quick checklist for safe testing:

Disconnect all power sources and record your motor’s voltage and current ratings.

Use a multimeter to measure resistance between armature terminals.

Test continuity between each terminal and the motor frame.

Power up and measure voltage across the terminals.

Perform insulation resistance tests.

Start the motor and monitor current, noise, and vibration.

Check polarity and brush conditions.

Feature | INEED Coin Brushless BLDC Vibration Motors | Traditional Micro Motors |

|---|---|---|

Longevity | Close to 500,000 cycles (5x longer) | 100,000 cycles |

Efficiency | 30% higher average speed | Standard speed |

Maintenance | Minimal care required | Frequent part changes |

Size | Ultra-thin (0.5mm thinner than previous) | Standard size |

INEED Coin Brushless BLDC Vibration Motors give you stable performance during testing. Their small size lets you design with more freedom. You get ultra-long life and reliable operation, even with series or parallel connection setups.

Monitor & Disconnect

Observe Operation

You want your 3V DC motor to run smoothly after you connect batteries. Start by watching how the motor behaves. Listen for odd noises or feel for extra heat. These signs can warn you about problems with current or voltage. If you use batteries in series or parallel, check that each battery has enough capacity to keep the current steady. Motors can draw more current when you use a series connection, so always keep an eye on the temperature.

Here’s a handy table to help you monitor your motor during operation:

Monitoring Method | Description |

|---|---|

Shock Pulse Method | Checks bearing health by amplifying and filtering signals. |

Insulation Resistance (IR) Test | Measures insulation; good if ≥ 10MΩ. |

Dielectric Absorption Ratio (DAR) Test | Looks at insulation over time; DAR > 1.6 is good. |

Winding Resistance Measurements | Finds high-resistance spots; should not exceed 10% of winding current rating. |

Winding Inductance & Capacitance | Compares values to spot unbalance. |

Motor Current Signature Analysis | Finds rotor issues by checking induced rotor currents. |

HighPot and Surge Testing | Tests insulation but use with care to avoid winding damage. |

If you use batteries in parallel connection, make sure each battery matches in voltage and current. This keeps the current balanced and avoids overload. Always check your series and parallel setups for loose wires or weak batteries.

Safe Disconnection

When you finish, disconnect the batteries safely. Turn off any switches first. Remove the batteries from the series or parallel connection one at a time. Never pull all batteries at once, especially in a series setup, because this can cause a sudden current spike. If you use a dc motor with high current, let it cool before you disconnect.

INEED Coin Brushless BLDC Vibration Motors give you peace of mind. These motors can last from 20,000 to over 50,000 hours if you follow good maintenance. Keep the bearings lubricated, monitor current, and avoid running the motor outside its voltage range. Use batteries with enough capacity and always double-check your series and parallel connections for safety.

You followed five steps to connect your 3 v dc motor to a battery with safety in mind. You checked every series and parallel connection for solid current flow. You used a multimeter to measure current at each series point and parallel junction. You watched for current spikes in series setups and balanced current in parallel groups. You made sure every series and parallel connection matched the motor’s current needs. You chose INEED Coin Brushless BLDC Vibration Motors for reliable current and long-lasting series and parallel operation.

Feature | BLDC Motors | Brushed Motors |

|---|---|---|

Lifetime | Exceeds 10 times longer | Shorter lifespan |

Application Suitability | High reliability applications | General use |

Maintenance | Lower maintenance required | Higher maintenance needs |

Use a multimeter to check the resistance of the motor before series and parallel connection.

Verify resistance at each series and parallel point to avoid current loss.

You kept current steady in every series and parallel setup. You double-checked each connection for safety. You watched current during operation and disconnected batteries from series and parallel groups safely.

FAQ

How do you choose the right batteries for a 3V DC motor?

You want batteries that match your motor’s voltage. Always check the label. If you use the wrong batteries, your motor might overheat or stop working.

Can you connect multiple batteries to increase power?

Yes, you can connect batteries in series for higher voltage or in parallel for more current. Always make sure the total voltage matches your motor’s rating.

What should you do if your batteries get hot during use?

Stop using the batteries right away. Hot batteries can mean a short circuit or overload. Let the batteries cool, then check your connections before trying again.

See Also

Utilizing 3V DC Motors Across Five Different Devices

Resolving Frequent Problems with 3 Volt Motors

Five Simple Steps to Excel with Arduino Vibration Motors

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry