3 Key DC Motor Components You Should Know

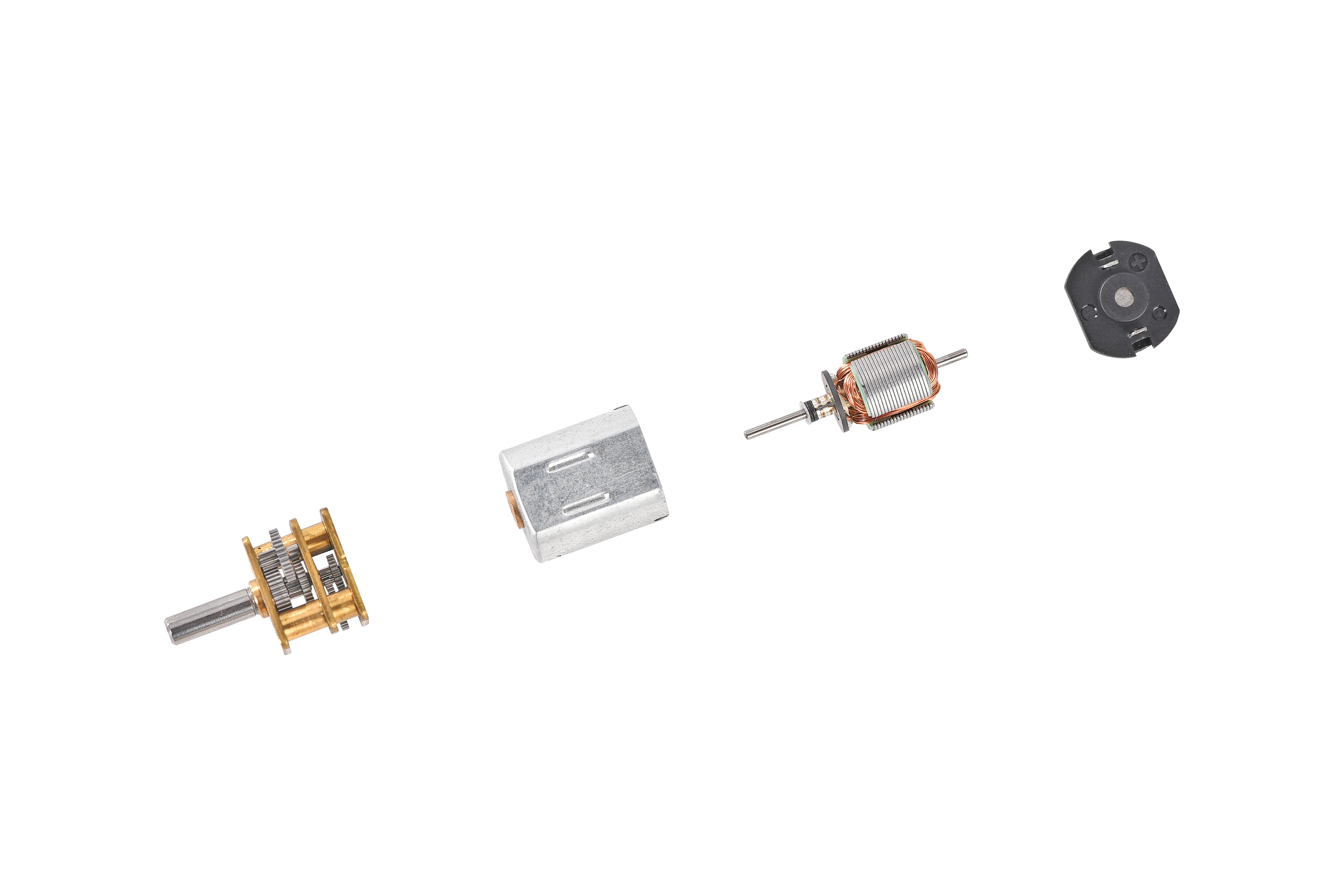

DC motor components utilize direct current to create movement. They require three main parts to function effectively. The rotor spins to generate motion, while the stator remains stationary and produces a magnetic field. The commutator aids the motor in operating smoothly by altering the direction of the current. These DC motor components collaborate to convert electricity into motion. Understanding how DC motors operate reveals how these components energize various machines.

Key Takeaways

The rotor turns inside the motor, making force to move things. It changes electrical energy into motion. Better rotor design makes motors work well.

The stator is around the rotor and makes a magnetic field. This field is needed for the motor to work. Its design affects how much energy the motor uses.

The commutator changes the current's direction in the rotor. This keeps the motor moving smoothly. It helps the motor keep steady force.

The rotor, stator, and commutator are all important parts. Knowing how they work together helps improve DC motors.

Making these parts better can save energy and make devices last longer. These motors are used in small tools and big machines.

Rotor

What is the Rotor?

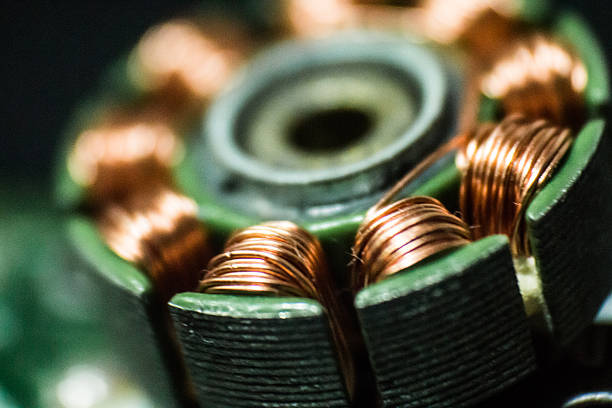

The rotor is a key part of a DC motor. It moves by spinning inside the motor. This happens because of the magnetic field and electric current working together. The rotor has three main parts: a core, windings, and a shaft. In brushed motors, brushes send current to the rotor windings. This makes the rotor spin and powers the motor's shaft. The spinning shaft helps the motor do mechanical work.

How Does the Rotor Work?

The rotor works using electromagnetic induction. When current flows through its windings, it creates a magnetic field. This field interacts with the stator's magnetic field. Together, they produce torque that makes the rotor spin. This process changes electrical energy into mechanical motion.

The rotor's design affects how well it works. Iron core rotors are heavier and less smooth. Ironless rotors are lighter and spin faster. Below is a table comparing the two designs:

Feature | Iron Core Rotor | Ironless Rotor |

|---|---|---|

Weight/Inertia | Heavy due to iron | Light without iron |

Smoothness | Less smooth | Very smooth |

Torque Changes | Big changes | Small changes |

Energy Losses | More losses | Fewer losses |

Speed | Slower | Faster |

Voltage Drop | High | Low |

Why is the Rotor Important?

The rotor is crucial for motor efficiency and performance. It creates torque, which turns electrical energy into motion. Studies show rotor losses, like heat from current, lower efficiency. Better rotor designs reduce these losses and improve motor performance.

Aspect | Explanation |

|---|---|

Rotor Loss | Energy lost as heat when current flows through the windings. |

Efficiency Impact | Rotor losses affect how well the motor works overall. |

Fixing Losses | Using bigger conductive parts can lower rotor losses. |

Knowing how the rotor works shows why it matters in DC motors. Whether brushed or brushless, the rotor keeps the shaft spinning smoothly for many uses.

Stator

What is the Stator?

The stator is the part of a DC motor that stays still. It surrounds the rotor and makes the magnetic field the motor needs to work. The stator is usually made of a steel core with wire windings. In brushed motors, it gives a steady magnetic field. In brushless motors, its windings work with the rotor's magnets. Without the stator, the motor can't create the force to spin the shaft.

How Does the Stator Work?

The stator works by making a magnetic field with its windings. When electricity flows through the wires, it creates an electromagnetic field. This field pushes the rotor, making it spin. The stator uses electromagnetic induction to turn electricity into motion.

The stator's design affects how well the motor works. For example, using silicon steel instead of solid iron lowers energy waste and boosts efficiency. The table below shows how stator design changes motor performance:

Stator Design Feature | Effect on Motor Performance and Reliability |

|---|---|

Topology | A 12S4P setup reduces torque ripple for better stability. |

Material Efficiency | The AYFA_Z core design gives the best efficiency. |

Materials | Switching to silicon steel cuts energy losses. |

Soft Magnetic Materials | Material choice affects weight and efficiency. |

Why is the Stator Important?

The stator is key to how the motor works. It creates the magnetic field that helps the rotor spin and produce force. This makes the motor run smoothly and use energy well. Improving the stator's design can make the motor more reliable. For example, using special materials can save energy but might cause noise or shaking.

Knowing how the stator works shows why it's so important. Whether in brushed or brushless motors, the stator keeps the motor running properly and is a crucial part of the system.

Commutator

What is the Commutator?

The commutator is a key part of a DC motor. It is a round piece made of copper sections on the rotor's shaft. Its main job is to switch the current's direction in the rotor windings. This switching helps the motor keep spinning smoothly. The commutator works with brushes that stay in contact as the rotor turns. Without it, the motor wouldn't create steady torque.

How Does the Commutator Work?

The commutator changes the current direction in the rotor windings. Brushes press against its copper sections while the rotor spins. These brushes send electricity from the power source to the rotor. When the rotor reaches certain spots, the commutator flips the current flow. This keeps the magnetic forces between the rotor and stator working together. It lets the motor spin nonstop.

Fun Fact: Even tiny misalignments in the commutator can stop the motor from working properly.

In high-power DC systems, special tools like R-SFCLs prevent commutator problems. Tests using PSCAD/EMTDC software show these tools improve system safety and lower risks during faults.

Why is the Commutator Important?

The commutator is vital for keeping a DC motor running well. It makes sure the rotor gets the right current direction to produce steady torque. This part also helps the motor handle different workloads easily.

Here’s why the commutator matters:

Continuous Motion: It keeps the rotor spinning without stopping.

Torque Generation: It ensures the motor creates steady torque for work.

Compatibility with Brushes: It works with brushes to keep electrical contact.

Learning about the commutator shows how DC motors work reliably. From small gadgets to big machines, this part is crucial for turning electricity into motion.

The three main parts of a DC motor—rotor, stator, and commutator—work together to change electricity into motion. Each part has a special job to make the motor run well. The rotor makes torque, the stator creates the magnetic field, and the commutator keeps the current flowing smoothly. Knowing about these parts can help you use DC motors better in things like robots, machines, and factories.

Studies show that understanding DC motor parts can save energy and make systems more reliable. The table below compares how advanced controllers and older ones manage motor performance:

Feature | POA-FOPD(1 + PI) Controller | Traditional Controllers |

|---|---|---|

Response Time | Very fast | Average |

Accuracy | Very good | Okay |

Robustness | Strong | Changes a lot |

Performance in Disturbances | Stays steady | Not steady |

Learning how DC motors work helps you see their importance in powering many devices. This knowledge is key to making motors more efficient and reliable for jobs like robotics and automation.

FAQ

How is a DC motor different from an AC motor?

A DC motor uses direct current to make things move. An AC motor uses alternating current instead. DC motors are great for jobs needing exact speed control, like robots or electric cars.

How do you take care of a DC motor?

Clean the motor often to get rid of dirt. Look at the brushes and commutator to see if they are worn out. Add oil to moving parts to stop friction and help the motor last longer.

Can batteries power a DC motor?

Yes, batteries can make a DC motor work. Batteries give direct current, which the motor needs. This makes DC motors good for gadgets you can carry or control from far away.

Why does a DC motor need a commutator?

The commutator makes sure the current flows the right way in the rotor. It switches the current to keep the rotor spinning, so the motor works well.

What are DC motors used for?

DC motors run things like fans, toys, and conveyor belts. They also work in big machines and electric cars because they are strong and dependable.

See Also

Identifying And Fixing Frequent Problems With 3 Volt Motors

Understanding The Mechanism Behind Vibrations In 3V Motors

Choosing The Best 3 Volt DC Motor For Your Needs

Typical Issues With 3 Volt Motors And How To Resolve

Learning To Interpret And Analyze Motor Diagrams Effectively

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry