12V Vibration Motors: Pros, Cons and Ideal Use Cases for Medium-Power Applications

You need small and efficient parts for medium-power gadgets. 12V vibration motors are perfect for this job. These tiny but strong motors help many devices work better. They create exact vibrations for tools like medical gear, wearables, and car systems. Their light weight and low energy use make them great for battery-powered devices. Whether for touch feedback or alerts, these motors are key to making easy-to-use gadgets.

Key Takeaways

12V vibration motors are small, light, and save energy. They work well in battery-powered gadgets.

These motors create precise vibrations, improving how gadgets like wearables, medical tools, and car systems feel to use.

Picking the right motor and battery can make batteries last longer and devices work better.

12V vibration motors can be used in many ways. They fit both home gadgets and big machines.

Adding these motors to projects can save money and improve how things work. They are a great choice for builders.

Understanding 12V Vibration Motors

What Are Vibration Motors

Vibration motors are small machines that turn electricity into vibrations. These vibrations happen when a weight inside the motor spins unevenly. You can find these motors in things like phones, smartwatches, and medical devices. They give physical feedback, like vibrations for alerts or notifications, to improve how users interact with devices.

A vibration motor has several parts: a rotor, an unbalanced weight, a case, terminals, and bearings. When electricity powers the motor, the rotor spins, moving the weight. This spinning creates vibrations that travel through the motor's case to the device. These vibrations are accurate and dependable, making them important for modern technology.

Key Features of 12V Vibration Motors

12V vibration motors are made for medium-power uses. They are small, light, and save energy, which makes them great for battery-powered gadgets. These motors run smoothly and spread vibrations evenly. This reduces damage to parts and helps them last longer while working well.

Here’s a comparison of two common 12V vibration motors:

Motor Model | NFP-RS-775DHV | ATO-MVB-20DC12-3 |

|---|---|---|

Voltage | 12V / 24V DC | 12V |

Speed | 4,000rpm – 8,000rpm | |

Power | 35W | 20W |

Force | - | 20 Kg, 0.2 kN |

Protection Level | - | IP65 |

Weight | 459g | 3kg |

These motors can do many jobs, like giving feedback in wearables or running small machines.

How 12V Vibration Motors Operate with Batteries

12V vibration motors work well with batteries, so they’re great for portable devices. When you connect a motor to a battery, it gets electricity. The rotor spins, and the weight creates vibrations. These motors use energy efficiently, helping batteries last longer.

To make batteries last, check the motor’s power needs. For instance, a motor using 0.3A and 35W will save energy and protect the battery. Using a good battery system also keeps the motor from draining too much power.

Picking the right motor and battery helps devices work well and keeps batteries lasting longer.

Advantages of 12V Vibration Motors

Small and Lightweight Build

12V vibration motors are great for small devices. Their tiny size and light weight make them easy to fit. They don’t add extra bulk to gadgets. This is helpful for wearables, medical tools, and robots where space matters.

These motors fit in tight spots, perfect for portable gadgets.

Brushless types need less care and last longer.

In robots, these motors give strong power without adding weight. This helps make smaller, smarter robots. You can pack more features into a compact design, which is key for modern tech.

Saves Energy in Battery Devices

12V vibration motors use little energy but work well. This helps batteries last longer in portable devices. They are a smart pick for gadgets that run on batteries.

Here’s a simple look at their energy use:

Metric | Range |

|---|---|

Efficiency | 2.2% - 3.5% |

Power Output | 1.3 W - 7.3 W |

Fuel Use | 4.6 g/h - 16.1 g/h |

Best Efficiency | 3.55% |

Choosing the right motor and battery setup saves power. This makes devices run longer without needing frequent charges. Good battery systems also stop overuse, keeping batteries healthy.

Useful for Many Medium-Power Tasks

12V vibration motors work in many different devices. They are used in electronics, cars, and industrial machines. Their flexibility makes them a popular choice.

For example, in cars, they give seat massages or send alerts. In medical tools, they create exact vibrations for tests. These motors work well in many places, showing their dependability.

Whether for wearables, robots, or medical tools, these motors fit the job. Their small size, energy-saving design, and custom options make them useful. They ensure great performance in all kinds of devices.

Cost-Effectiveness and Ease of Integration

12V vibration motors are a budget-friendly choice for medium-power tasks. They work well with different power sources, making them useful in many fields. These motors can be added to cars, portable gadgets, and solar-powered devices. For example, they match the voltage of solar panels, making designs simpler. This reduces extra parts, saving time and money during development.

Their small size and light weight make them easy to use. They fit into tiny devices without big changes. Whether for a wearable gadget or medical tool, these motors adjust to your needs. Installing them is simple, so you can focus on improving your device.

These motors also save money over time. They use less energy, helping batteries last longer in portable devices. This lowers costs and improves battery life. By picking 12V vibration motors, you get both affordability and good performance.

Better User Experience with Tactile Feedback

Tactile feedback helps users interact better with devices. 12V vibration motors give steady and accurate vibrations, perfect for haptic feedback. You see this in phones, game controllers, and medical tools. The vibrations respond to actions, making devices easier to use.

For example, in wearables, vibrations can alert users without sound. This is helpful in noisy places or when silence is needed. In cars, vibrations improve safety by warning about lane changes or parking.

You can also customize how the vibrations feel. Change the strength, speed, or length to fit your needs. This makes the feedback feel natural and matches the device’s purpose. Adding 12V vibration motors improves user experience, making products more enjoyable and easy to use.

Ideal Use Cases for 12V Vibration Motors

Consumer Electronics and Wearables

12V vibration motors are common in electronics and wearables. They improve how devices feel by adding vibrations. For example, smartwatches vibrate to alert you about calls or texts. Fitness trackers use vibrations to remind you of goals or activities.

In gaming controllers, these motors make games feel more real. Phones use them for quiet alerts, so you stay updated without noise. Their small size and light weight make them perfect for wearables where space is tight.

When used with battery packs, these motors save energy. They help batteries last longer, even in small devices. Their efficiency makes them great for portable gadgets.

Automotive Applications (e.g., Seat Massagers, Feedback Systems)

12V vibration motors are important in cars. They make rides more comfortable and safer. Seat massagers use these motors to give relaxing vibrations. You can change the strength to match what you like.

Cars also use these motors for safety alerts. Vibrations warn you about lane changes, parking issues, or blind spots. These signals help you stay aware without needing to look or listen. This makes driving easier and safer.

Car designers pair these motors with battery systems for steady power. Good battery setups save energy and keep the motors working well. This ensures they perform reliably in different car features.

Industrial Equipment and Small Machinery

In factories, 12V vibration motors help small machines work better. They are used in tools like sorting machines or vibrating feeders. These motors make manufacturing faster and more accurate.

You might see them in handheld tools for sanding or polishing. Their light weight makes them easy to use for long periods. They also work in portable testing tools, giving steady vibrations for accurate results.

With battery packs, these motors become portable for industrial tasks. Good battery management keeps them running longer and stronger. This makes 12V vibration motors a useful tool for small machines.

Medical Devices and Healthcare Equipment

12V vibration motors are important in medical tools. They give steady vibrations, helping devices work better. You can find them in health monitors, infusion pumps, and diagnostic tools. These motors ensure accurate results in critical tasks.

In health monitors, they alert users with vibrations. For example, they can warn about irregular heartbeats or remind you to take medicine. Vibrations are helpful for people who miss sound or visual alerts. Their small size fits well in tiny medical gadgets without adding weight.

Infusion pumps also use these motors. They help control the smooth flow of fluids. These motors save energy, making batteries last longer. This is important for portable medical devices. Lightweight motors make devices easier to carry and use.

These motors are tough and last a long time. They handle constant use and harsh conditions in medical settings. Whether in wearable devices or diagnostic tools, they improve healthcare by making equipment more reliable and user-friendly.

Robotics and Prototyping Projects

12V vibration motors are key in robots and prototypes. They create vibrations needed for movement, feedback, and sensing. Their small size and light weight make them perfect for compact robots.

Robots can use these motors for touch feedback. For example, a robotic arm can vibrate when it grabs something. This helps the robot work better and more precisely. These motors are easy to add to prototypes, so you can test ideas quickly.

Prototypes need parts that are flexible and affordable. 12V vibration motors fit these needs. They work with batteries and save energy, helping robots run longer. This is great for portable robots that need to work for hours.

You can also adjust these motors for specific projects. Change the vibration strength or how they are mounted to fit your design. This makes them popular for engineers, hobbyists, and researchers building new robots.

Adding 12V vibration motors to your robot projects improves how they work. These motors are reliable and help you get better results in your designs.

INEED's Role in 12V Vibration Motors

Overview of INEED's Vibration Motor Options

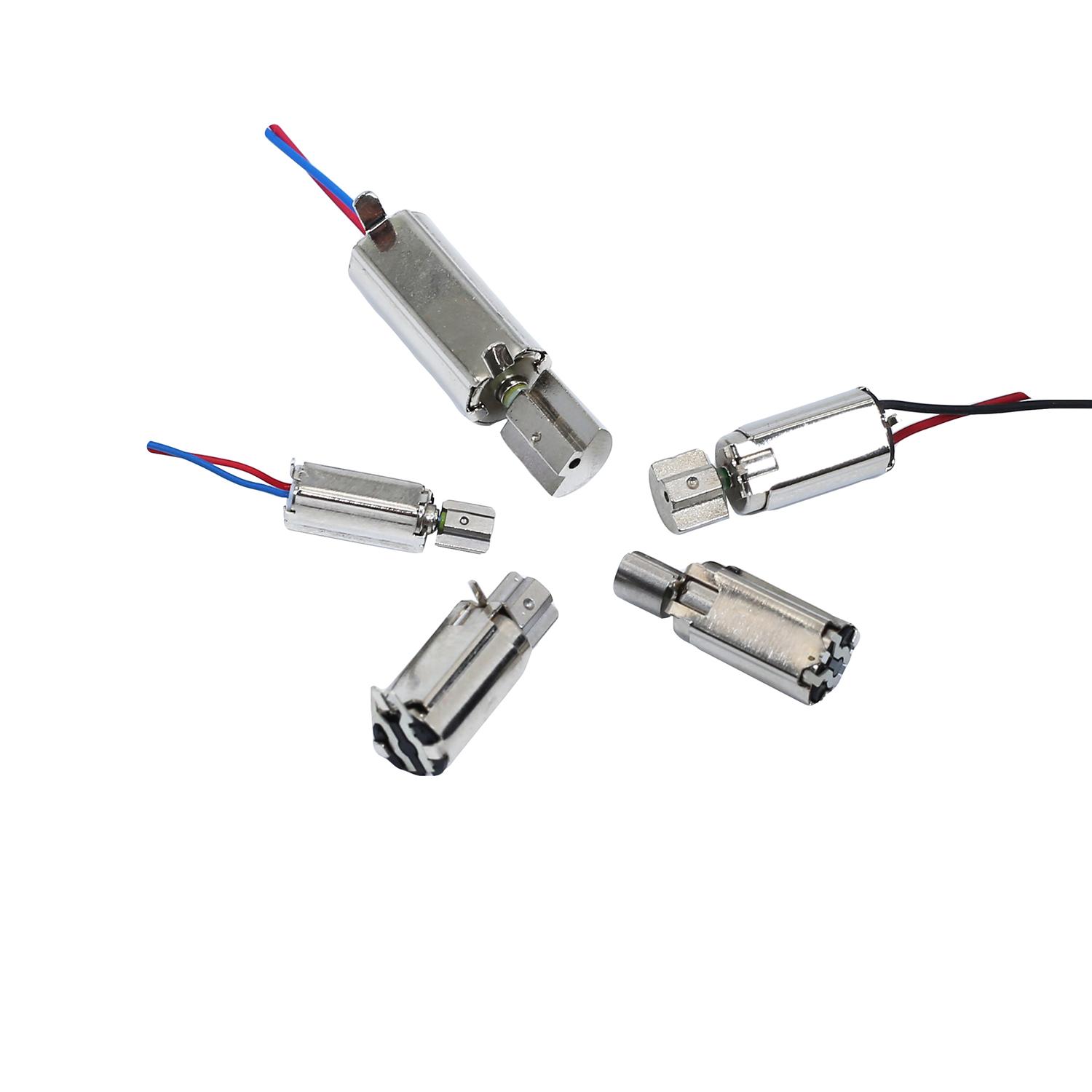

INEED makes many types of 12V vibration motors. These motors are great for medium-power devices. They include coin motors, coreless DC motors, and LRAs. Each type has a special use, like wearables or industrial tools. INEED focuses on making reliable and energy-saving products. Their motors are small, light, and perfect for portable gadgets.

You can also customize these motors. Choose wire lengths, mounting styles, or vibration strength. This makes sure the motor fits your device perfectly. Whether for medical tools or robots, INEED has the right motor for your needs.

Custom Features of INEED's Coreless Vibration Motors

INEED’s coreless motors are easy to customize. These 12V motors are small and work well in tight spaces. You can change wire length, mounting style, or vibration power. The coreless design makes them lighter and more efficient.

These motors are great for precise feedback. For example, they improve gaming controllers by adding vibrations. They respond quickly and last a long time, saving money. INEED lets you design motors that match your device’s needs.

Uses of INEED's Micro DC Motors in Medium-Power Devices

INEED’s micro DC motors are useful for medium-power gadgets. These 12V motors work in many industries. They are small but powerful, fitting into tiny devices easily.

In healthcare, they power pumps and testing tools. In robots, they give accurate movements and feedback. They save energy, helping batteries last longer in portable devices. INEED’s micro DC motors are reliable and flexible, making them great for your projects.

12V vibration motors are great for medium-power devices. They are small, save energy, and work in many gadgets. These motors are perfect for wearables, medical tools, and robots. They give accurate vibrations and work dependably.

INEED makes high-quality 12V vibration motors for your needs. You can customize them to fit your projects. Use them in healthcare, cars, or factory tools. INEED offers smart and reliable designs.

Check out INEED's 12V motors now. They are strong, efficient, and budget-friendly for your devices.

FAQ

Why are 12V vibration motors good for medium-power devices?

They are small, save energy, and work in many gadgets. You can use them in wearables, medical tools, and robots. They work well while using little power, helping batteries last longer. They also fit easily into different designs.

Can 12V vibration motors be customized for specific uses?

Yes, you can change them to fit your device's needs. You can adjust wire length, how they are mounted, or vibration strength. This makes them useful for healthcare, cars, or factory machines.

How do 12V vibration motors make devices better for users?

They give vibrations that improve how devices feel. For example, they vibrate for alerts in smartwatches or game controllers. This makes gadgets easier and more fun to use.

Are 12V vibration motors good for battery-powered gadgets?

Yes! These motors use very little energy, so they are great for battery devices. Their design helps batteries last longer, so you don’t need to charge often.

Where can INEED’s 12V vibration motors be used?

You can use them in electronics, cars, medical tools, and robots. INEED offers options you can customize to fit your project. Their motors are reliable and work well for many tasks.

See Also

Designing Small Vibrating Motors for Limited Space Environments

Types and Uses of Small Battery Motors in Vibration Systems

A Comprehensive Overview of Vibration Motors and Their Uses

Understanding Vibration Motors: Varieties, Uses, and Mechanisms

Investigating How Vibration Motors Are Used in Today's Industries

Get Custom Micro DC Motors from

INEED Motors!

Leading Brand in Vibration Motor Manufacturing Industry